Discover Pharmapack's Efficient Cartoning Machine Solutions!

From flat carton blanks to sealed cartons packed with products, the magic lies in an integrated component on the packaging line: the cartoner machine. In Pharmapack, your diverse packaging needs can be satisfied with professional solutions. And in this page, we will focus on the cartoning machine.

Learn More

What is the Cartoning Machine?

A cartoning machine is a specialized piece of equipment that automates the process of placing products into cartons or boxes, ready for distribution. These machines come in various configurations, from semi-automatic to fully automated, and are for single-piece packing. Their working process might include carton forming, product insertion, leaflet insertion, closure and sealing, batch coding and marking, and quality control.

Types of Cartoning Machines

Vertical Cartoning Machines

Vertical cartoner machines are characterized by their ability to load products into cartons vertically, typically from the top. They are commonly employed for packaging products such as bottles, tubes, and pouches.

Horizontal Cartoning Machines

Horizontal cartoning machines load products into cartons horizontally, usually from the side. They are known for their versatility and ability to handle diverse product sizes and shapes.

For instance, Pharmapack's horizontal cartoning machines can pack bottles made of plastic or glass. Oral solution bottles, such as ampoules and vials, are acceptable. They are also ideal for blister pack cartoning and flexible packaging cartoning, like small sachets of herbal remedies and coffee sticks.

Continuous Cartoning Machines

Continuous cartoning machines operate with cartons moving through the machine at a constant speed. They are designed for high-speed production lines where efficiency and throughput are critical, making them well-suited for products with consistent packaging requirements.

Intermittent Motion Cartoning Machines

Intermittent motion cartoning machines operate in a start-stop manner. The carton is stopped and held in place while the product and the instruction manual (if there is any) are loaded into it. Once they are placed, the carton is then moved to the next station for closure, sealing, and labeling. These machines are often chosen for their ability to maintain accuracy and consistency in packaging, especially for products that require careful handling.

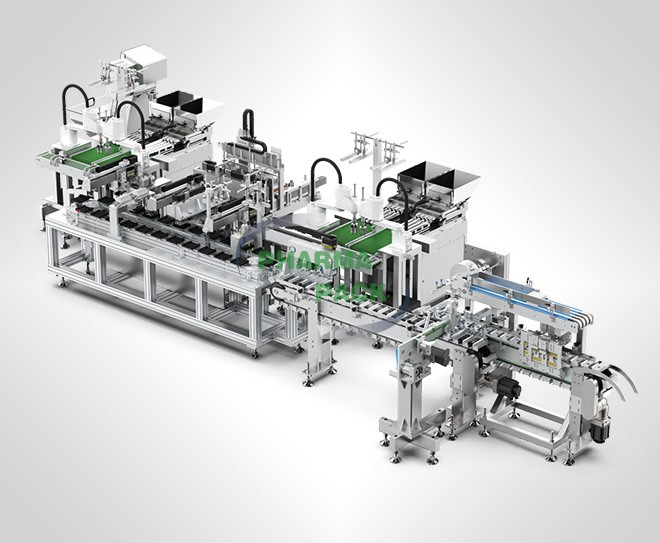

Pharmapack's Cartoning Machines

ALFBC-40 Continuous Horizontal Cartoner

This machine offers efficient cartoning with a maximum throughput of 400 cases per minute. Its alloy chain conveyors ensure stable, quiet operation. Servo motors enable flexible carton handling, while mechanical pushers ensure high-speed, stable insertion. A special flapping mechanism seals cartons effectively.

Driven by the main motor with overload protection, it features easy adjustment, suspended mounting for easy maintenance, and in-feeding detection sensors for optimized operation. User-friendly PLC and HMI enhance ease of use and troubleshooting. Ideal for streamlined packaging processes, it combines versatility with reliability.

Find Out More

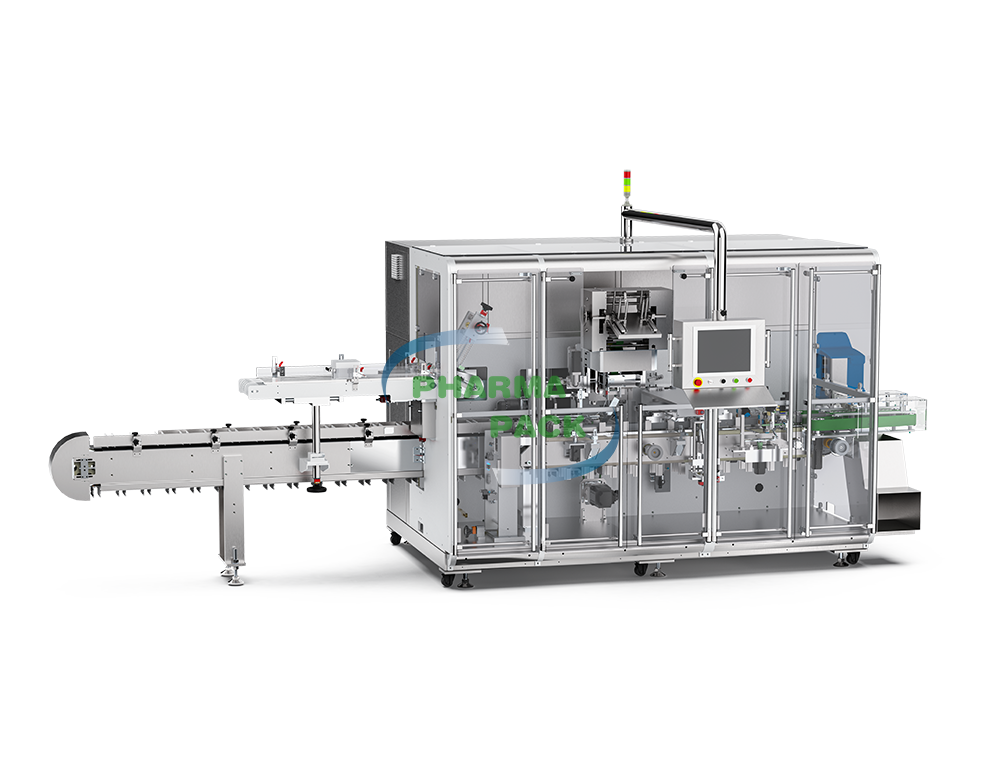

LFBI-10 Intermittent Horizontal Cartoner

This model is engineered with a peak production speed of 100p/min while meeting GMP standards. Its compact "Balcony" structure ensures easy maintenance and cleaning. Equipped with a scratch-resistant conveyor chain, it handles cartons gently, which is ideal for fragile products.

Featuring a sophisticated mechanical drive system and a user-friendly PLC controller with an intuitive touch interface, it offers seamless operation. With versatile sealing options, including hot melt glue, it's tailored for pharmaceutical and cosmetic packaging, delivering efficiency and reliability at high speeds.

Find Out More

ALFBC-25 Continuous Horizontal Cartoner

This option has a tank-construct design that houses driving and auxiliary parts, ensuring sanitation and easy maintenance. The utilization of the timing PU conveyor offers steady and quiet operation, while the unique servo motor system allows versatile adjustments for carton handling.

Meanwhile, the dual servo motors in the insertion part ensure swift and precise placement. Its smooth operation is further enhanced by a unified motor drive and the digital indicator for adjustments. Equipped with overload protection, manual and electrical jog functions, and a product inspection system, it ensures safe, efficient, and quality-controlled packaging at a maximum speed of 250 cartons/min.

Find Out More

Applications of Pharmapack's Cartoning Machines

Food Packaging

Pharmapack's cartoning solutions ensure efficient and hygienic packaging, maintaining product freshness and integrity. From erecting cartons to filling and sealing, they streamline food packaging, enhancing productivity and reducing labor costs.

Pharmaceutical Packaging

We concentrate on developing equipment that meets the stringent requirements of pharmaceutical packaging, ensuring accurate position and tamper-evident packaging for medications. Whether it's blister packs, bottles, or vials, Pharmapack's cartoner machines deliver consistent and uniform packaging, meeting the highest safety and compliance standards.

Personal Care Product Packaging

Our cartoning equipment is also helpful for personal care brands to achieve attractive and functional packaging. Their versatility and flexibility enable precise control and efficient operation, making them supportive allies to enhance product appeal and consumer satisfaction.

Some of Our Renowned Clients

Possessing over 400 patents and global application expertise of over 1500 production lines, we craft premium automatic packing machines that comply with CE, UL Certification, and CSA standards and adhere to GAMP, FDA (CFR21), cGMP, and TGA standards. Since 2002, our professionalism has led to partnerships with many renowned clients.