A single-row automatic packing machine is designed to package products automatically in a single row. The demand for automatic packing machines has been increasing due to the demand for efficient and reliable packaging solutions in various industries such as food, beverage, pharmaceutical, and cosmetics. According to a report by MarketsandMarkets, the global packaging machinery market size is expected to grow from USD 46.4 billion in 2022 to USD 56.7 billion by 2027, at a CAGR of 4.1% during the forecast period. This growth can be attributed to the increasing demand for packaging machinery from various industries. In this article, we introduce the new product LFVS-01S of Pharmapack and present the 3-in-1 product features of this new product in detail.

Overview of Pharmapack’s New Product

Pharmapack LFVS-01S is a single-row automatic packing machine. As a new product of Pharmapack, this product has the functions of metering, filling, forming, sealing, cutting, and more. This machine is suitable for metering and packaging granules, powders, pills, and liquids, and it also can be widely used in food, daily chemical, and other industries.

The LFVS-01S usually consists of a film conveying system to convey the film to the packaging section that automatically packs the product into the required packaging. The packaging includes forming, vertical sealing, metering, filling, and horizontal sealing to ensure the product can be packaged more efficiently and accurately.

This new product has many outstanding features in terms of performance. For instance, it is equipped with a high-precision I-Mark remote control and servo drive, which can ensure accuracy when packing and reduce noise. The machine system has an industrial computer control system that allows operators to set parameters conveniently.

New 3-in-1 technology in LFVS-01S single-row automatic packing machine

The device consists of 12 main structures in total. In addition to the advantages mentioned above, its 3-in-1 technology is an important item as a functional breakthrough. The previous products were one machine with only one feeding method, but this newly developed single-row automatic packing machine designed by Pharmapack can carry out packaging in three ways on one machine. Here are the main introductions to the 3-in-1 LFVS-01S:

1. Liquid metering

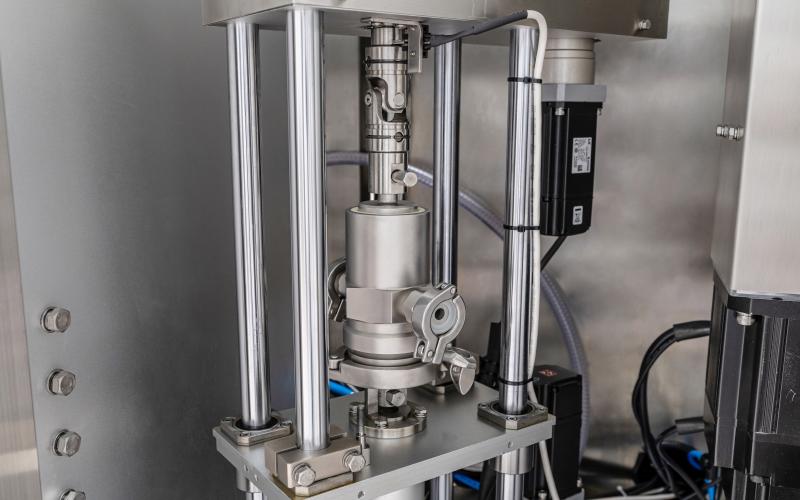

Liquid metering in single-row automatic packaging machines refers to measuring and distributing a predetermined amount of liquid product to each packaging unit. LFVS-01S uses a servo motor to drive a ceramic pump to complete the metering of materials. It can individually adjust the parameters of products in different specifications to make the products more convenient and quick to fill in.

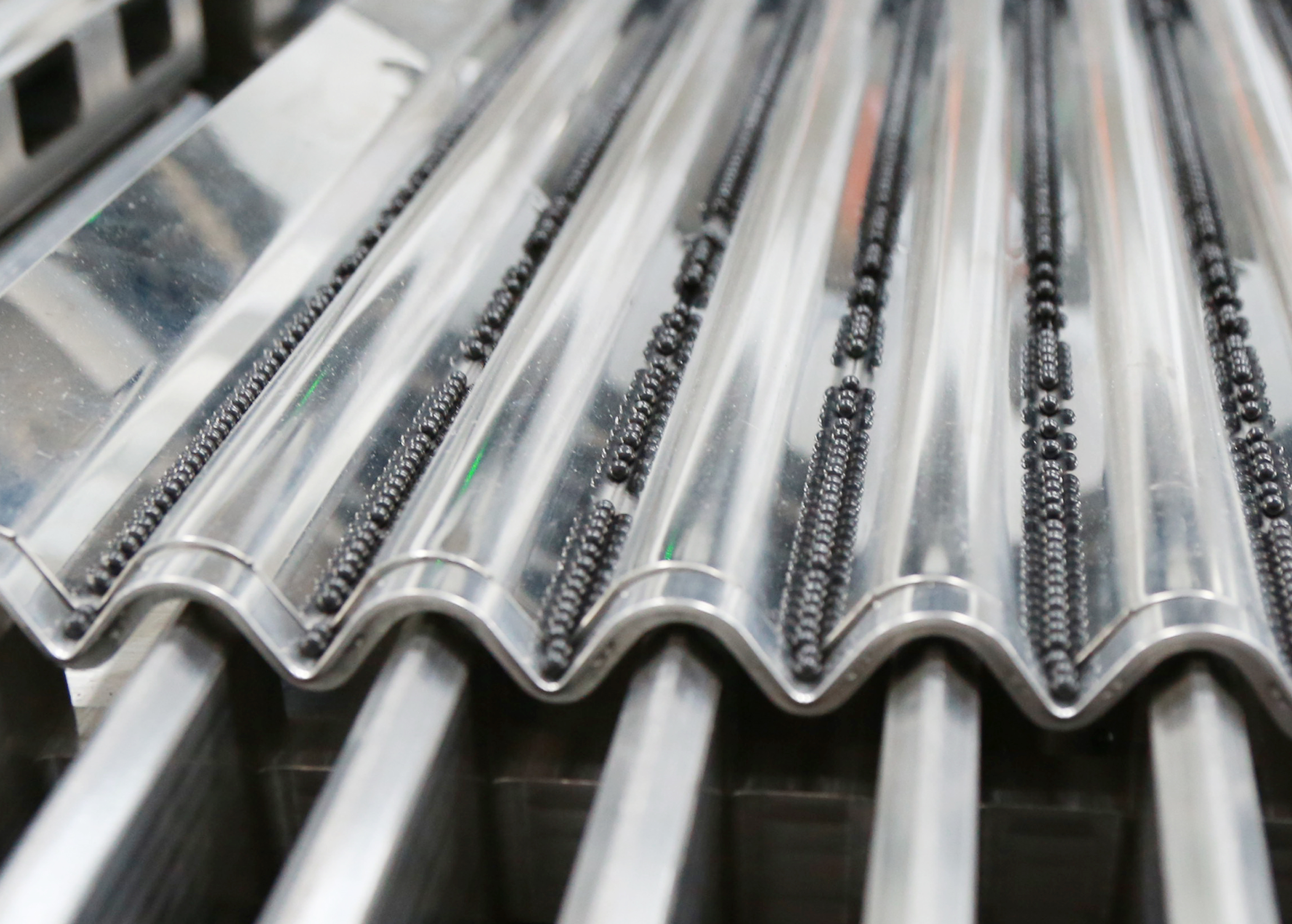

2. Granule counting metering

The counting mechanism is mainly used for granule counting. LFVS-01S can be widely used for counting granule preparations in food and pharmaceutical industries, such as pills, sugar-coated tablets, soft and hard capsules, and other shapes of medicine particles. A servo system controls the material gate, which can achieve faster speed and higher precision during operation. Furthermore, this device uses a servo motor to rotate and fill the blanking, reducing noise and avoiding the problem of tablet omission at the end of the material gate.

3. Servo-screw metering

Servo-screw metering is a method of accurately measuring and dispensing precise product quantities (usually powdered or granulated) into containers in single-row automatic packing machines. The process involves using a screw conveyor driven by a servo motor to transport the product from a hopper to a funnel-shaped container. The speed and rotation of the screw conveyor can be adjusted to precisely control the amount of product dispensed, ensuring each container is filled with the correct amount of product. Servo motors provide high precision and control, which helps reduce waste and increase productivity.

Pharmapack focuses on the R&D, manufacturing, and integration of intelligent packaging line production systems. Its new product LFVS-01S is widely applicable to granules, powders, pills, and liquids, and the measurement materials can be switched according to the required products. Through the 3-in-1 metering mechanism, one machine can be used for multiple purposes.

Additionally, all parts of this equipment that are in contact with the product are made of stainless steel and aluminum, and its higher hygiene design prevents the equipment from rusting and polluting after use. It is worth mentioning that LFVS-01S complies with GMP environmental requirements. All its control system components have international standardization certification and have undergone strict inspection and testing to ensure the reliability of various functions.

Contact us if you would like to know more information!

Related articles:

1. All You Need to Know about Automatic Case Packer (2023)

2. Why Investing in Stick Packaging Machines: Risks and Performance Evaluation

3. The Key Role of Artificial Intelligence in the Pharmaceutical Industry