What is a counter machine?

The counter machine is used to calculate the quantity of items. It usually determines the quantity of items by using sensors, counters, weighing devices, or other technologies, and can be used for packaging, sorting, inspection, and other applications. Different types of counters can be used for different kinds of items, such as pills, coins, screw, etc.

The working principle of the counter machine:

Manually or automatically pour the drug particles into the top hopper. By adjusting the primary, intermediate, and final vibration feeders appropriately, the stacked drug particles in the hopper gradually evolve into continuous straight strips along the vibration groove plate and slide down to the feeding port. Then, the drop detection channel is used one by one, and the principle of photoelectric effect is adopted. When the drug particles fall, the working signal generated by the infrared dynamic scanning sensor is input to the high-speed microprocessor MCU, The counting function is achieved through the cooperation of electronics and machinery, which can ensure the accuracy of the number of pills. When the number of tablets filled in the bottle meets the set parameter value, all the set number of pills will be canned out of the bottle, and after completing the loading of pills, they will be transported to the next process.

Advantages of counter machines:

1. Improve the counting accuracy: using sensors, counters and other technologies can greatly improve the accuracy of item counting and avoid errors that may occur in the traditional manual counting process.

2. Increase work efficiency: The counter machine can quickly complete counting tasks faster than manual counting, thereby improving production efficiency.

3. Time and effort saving: Using a counter machine can reduce the time and labor costs of manual counting, thus allowing for the concentration of human resources on other important tasks.

4. Reduce waste: Through automatic counting, it is possible to reduce waste or defective products caused by human error in counting, and to better control the production process, thereby reducing waste and losses.

5. Can be tracked and recorded: The counter machine usually tracks and records the counting results, which can be used for quality control, inventory management, sales analysis, and other purposes.

Application scenarios of counter machines

The counter can be applied to the following industries and scenarios:

1. Pharmaceutical industry: counter machines can be used for drug packaging and packaging, improving production efficiency and ensuring accurate measurement.

2. Food industry: The counter machine can be used for food packaging and sorting, such as potato chips, chocolate, candy, etc.

3. Electronics industry: The counter machine can be used for counting and packaging electronic parts.

3. Toy industry: counter machines can be used for counting and packaging toys.

4. Automotive industry: The counter machine can be used for counting and inspecting automotive components.

5. Logistics industry: counter machines can be used in areas such as inventory management and order processing.

6. Other industries: The counter machine can also be applied to various other industrial fields, such as hardware manufacturing, pharmaceuticals, cosmetics, household products, etc.

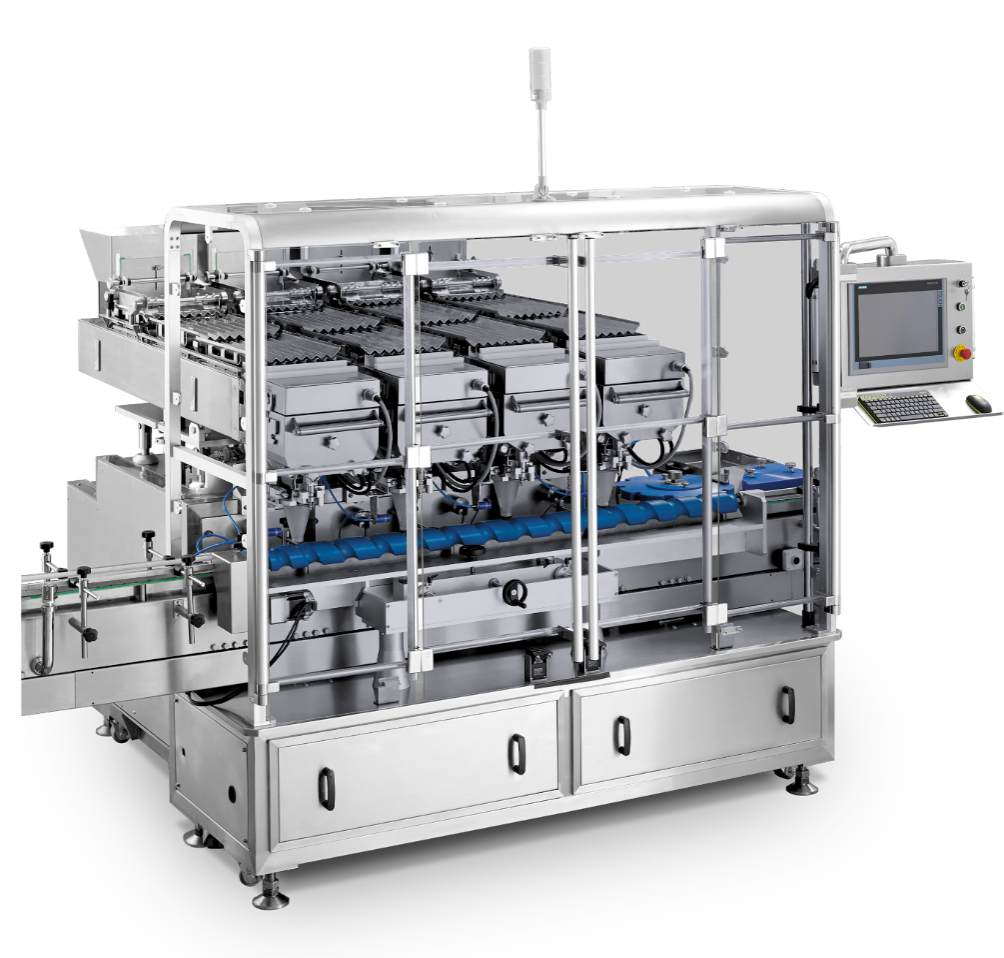

Product recommendation: Pharmapack's modular counter machine

Compared to electronic counter machines, modular counter machines have the following advantages:

The servo response speed is stable at 18ms, with a maximum speed of 10ms. It will not change with usage time and is almost unaffected by dust. It can continuously move bottles, replace nozzles, and replace screws in a shorter time. Fault alarm, module independent operation, single maintenance, and efficiency are not affected.

1. Modular counter ALFM-40CWS

Maximum production speed: 30000 capsules/minute, with a single bottle capacity of 1-1000 capsules. The vibrator is driven by a voice coil DC motor, and the servo vibration comes with feedback function, which can better ensure the balance of feeding, smooth transportation of drug particles, and even arrangement

The maximum production speed is 20000 capsules per minute, with a single bottle capacity of 1-1000 capsules. Compared to the traditional positive cylinder intermittent feeding method, the screw feeding method is adopted for bottle feeding, which has a faster continuous feeding speed and smoother operation, completely avoiding the impact and collision problem that the traditional positive cylinder intermittent feeding method may have on the medicine bottle.

If you would like to learn more about the Pharmapack, please call us immediately and we will be happy to assist you.