In the field of medicine, Paper Inserter Machine are a very important automation equipment. The main function of a paper stuffing machine is to feed materials such as paper or cardboard into corresponding packaging boxes, boxes, or bags. Paper Inserter Machine can effectively improve production efficiency, reduce labor costs, and have excellent stability and reliability. In addition, with the development of science and technology, modern Paper Inserter Machine have become more intelligent, such as automatically adjusting speed and identifying material size, further improving production efficiency and product quality.

Working principle of Paper Inserter Machine LFIP-10:

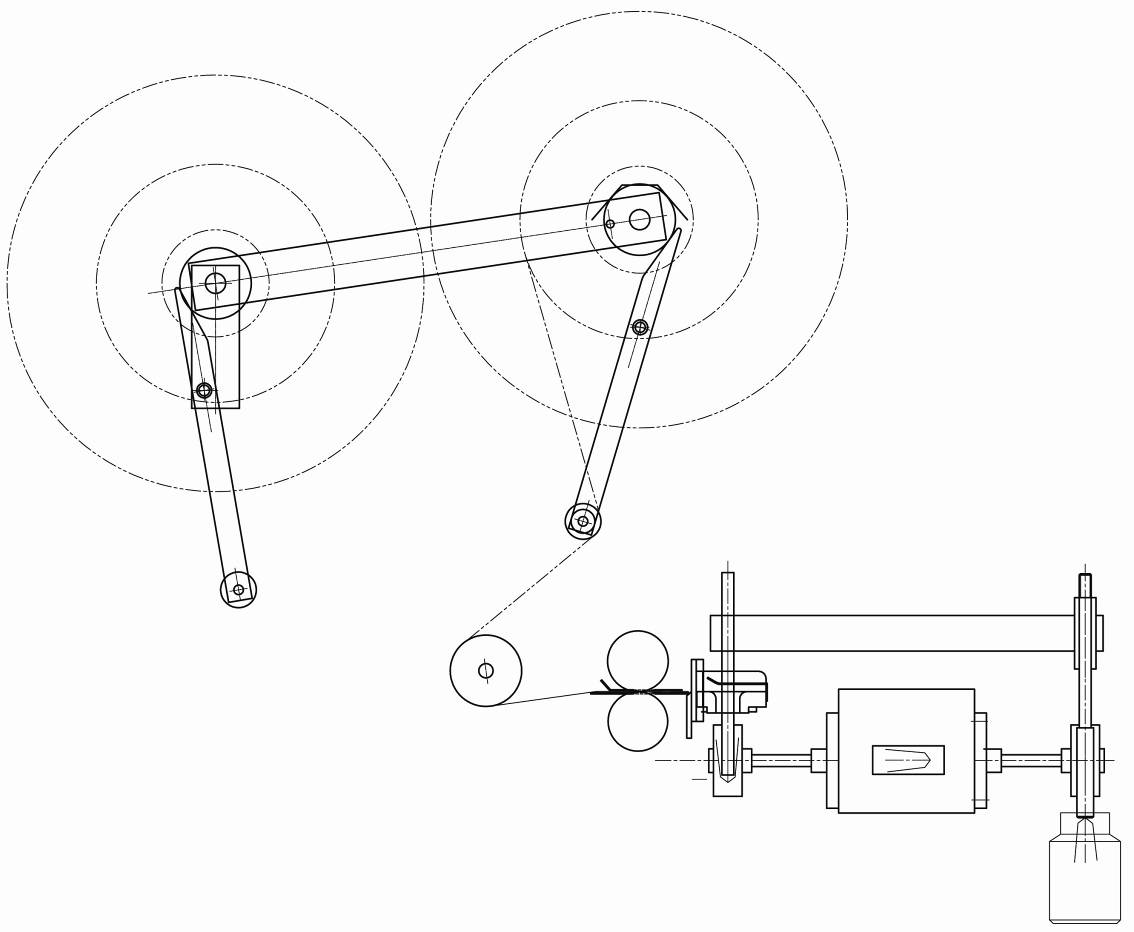

Through cam, ratchet and other mechanisms to achieve paper feeding, Paper Cuttings and other actions; The gear drives the crank connecting rod mechanism to achieve pre filling and paper filling actions. Flexible movement, fast speed, no paper flying, low noise, and reliable positioning.

Performance advantages of LFIP-10 Paper Inserter Machine machine:

1. Adopting programmable logic controller (PLC) control, Chinese interface touch screen, easy to learn and operate;

2. The German SEW motor and splitter are precisely positioned to ensure the complete placement of the roll of paper into the bottle;

3. Unique reverse corking technology ensures the quality of the corking paper, prevents the edges and corners of the paper from exposing the outside of the bottle, and avoids affecting the subsequent capping and sealing processes;

4. Automatic start with bottle, automatic stop without bottle;

5. Dual workstation uncoiling can achieve non-stop paper changing or multiple sheets can be inserted at once;

6. The machine height is low and adjustable, suitable for various specifications of bottles;

7. The entire machine is made of stainless steel or other materials that meet GMP requirements;

8. Equipped with various protective devices to ensure the safety of operators;

9. It can be wired or used alone.

The traditional manual packaging method usually requires a lot of manpower and time, and cannot meet the needs of large-scale production. The paper stuffing machine can effectively improve production efficiency, reduce labor costs, and maintain high-quality standards through automated operations. Paper Inserter Machine can package various types of pharmaceutical products, place them in drug boxes, bottles, or other drug containers, and add accessories such as instructions and labels to them. This effectively protects the drug from external pollution and damage, making it safer and more reliable. PPPHARMAPACK. It is recommended that the maximum production speed of the LFIP-10 paper stopper is 200 bottles per minute, suitable for bottle body square bottle diagonal lines of 35-100mm and square bottle diagonal lines of 35-100mm. It will be a good assistant for Paper Inserter Machine.