Friends familiar with Pharmapack products should know that we have both bottle counting machines and capping machines, such as our products: modular counting machine ALFM-40CWS, modular counting machine LFM-32C, rotary capping machine ALFCR-2510M-01, linear capping machine LFCL-20FN, etc. So what kind of machine is a counting capping machine? What performance characteristics does it have that help us improve the efficiency of pharmaceutical packaging? Below, the editor will take you to learn about the LF-0601C integrated machine with several spin caps!

What is a All-in-One Machine (Counter and Capper)?

The integrated machine for counting, filling, and sealing is an automated equipment used for counting, filling, and sealing. It can be adjusted as needed to accommodate containers and granular products of different sizes and shapes. This equipment has the characteristics of high efficiency, accuracy, and stability, and can be widely used in packaging production lines in industries such as food, medicine, and cosmetics.LF-0601C is tailored for the counting and filling of special medicine such as easy contaminated, moisture-prone, toxic and corrosive drugs. It creates a relatively clean environment by using aseptic isolation hood and negative pressure generated by the exhaust system to avoid external pollution and contact with operators.

Performance characteristics of the All-in-One Machine (Counter and Capper)

(1)Suitable for soft and hard capsules, transparent capsules, tablets, pills and other solid granules.

(2)Suitable for rotary screw cap and anti-theft cap.

(3)GMP compliance. AISI 316L stainless steel contact parts and frame.

(4)Compact structure and all electrical control components are sealed to avoid drug powder affecting the service life.

(5)Click the touch screen to control the pneumatic device to lock or loosen the vibrating plate, without tools for disassembly.

(6)Adopt embedded buckle structure, easy to disassemble, clean, use and maintain.

(7)Automatic alarm when detecting empty bottles, fallen bottles.

(8)With various self-protection devices during the normal operation, no need for special personnel to take care.

(9)Automatically sort and screw cap, reducing the labor intensity.

(10)A complete set of Festo and SMC pneumatic components. Use Germany SEW variable frequency speed regulating motor to ensure accurate and uniform action.

(11)12 tracks converge into one filling nozzle, with fast filling speed.

(12)With vibratory filling device, the filling nozzle firmly locates the bottle mouth when filling tablets. Such design makes sure that large tablets don't block bottles and small tablets don't drop out from bottles.

(13)With capping detection at the exit for rejecting improper capping.

Working principle of the All-in-One Machine (Counter and Capper):

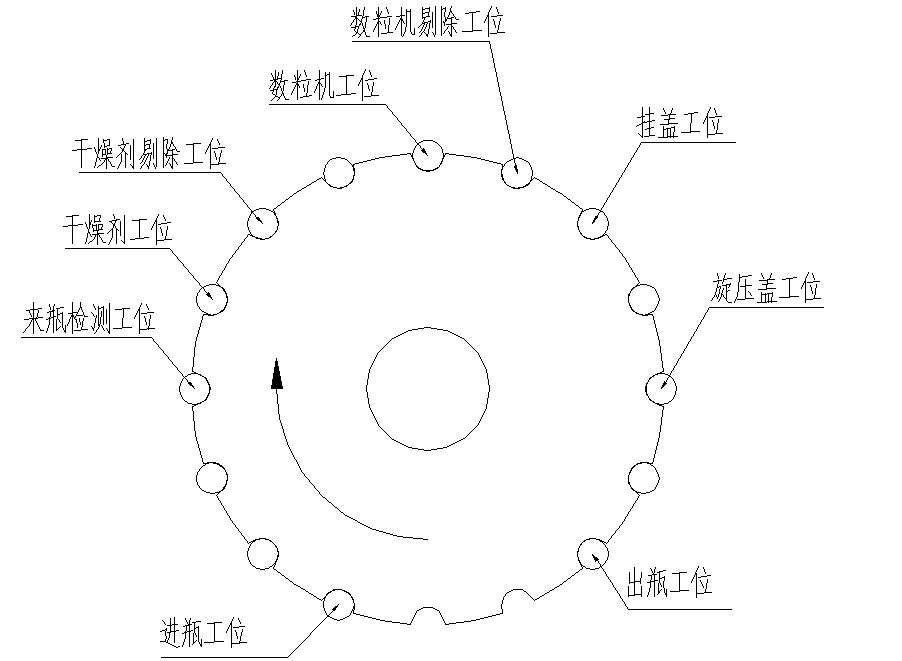

Bottles enter the star wheel via the conveyor belt. Each work station at the star wheel has different functions, implementing sachet/cotton inserting, tablet counting, capping, etc. The counting head adopts the cooperation of electronic and mechanical device to count tablets, then a certain amount of tablet will be filled into bottles. After being filling, bottles are delivered forward via star wheel. And caps are lifted from the hopper to the sorting turntable via the elevator, then they are sent out at a specific direction and flow into the cap chute to the outlet. When bottles come in, caps will send out for cap screw-on. Controlled by the servo motor, the capping head is going down as the declining of the capping shaft. After capping, bottles will move to the detection system. Missing caps, cross caps, misaligned caps, no foils will be rejected.

Why choose a All-in-One Machine (Counter and Capper)

Firstly, the integrated machine with several spin caps has high efficiency. It can complete the operations of counting, filling, and sealing a large number of products in a short period of time. The maximum working efficiency of the LF-0601C machine is 50 bottles per minute. This improves production efficiency and reduces labor costs.

Secondly, the integrated machine with several spin caps has high accuracy. It adopts advanced control systems and precise sensors to ensure the accuracy of the weight and filling amount of powder or particles in each container, so that each product meets the same standard and ensures stable product quality.

Thirdly, the integrated machine with several spin caps has high reliability. It is made of high-quality materials and has a compact structure. The electrical and hydraulic components used have also undergone strict selection and testing, ensuring that the equipment can operate for a long time and is not prone to malfunctions.

More automatic packaging machinery products can be found on the official website of Pharmapack. Pharmapack has a history of over 20 years in manufacturing and selling automatic tablet counters, particle capping machines, counting machines, capping machines, and other products. We have a good reputation among our customers, who trust us and choose us as a trustworthy supplier. Welcome to consult!