With the continuous development of various industries, the production efficiency and quality requirements are getting higher and higher. In industries such as food and medicine, bottles, as a common packaging material, are becoming more and more important in the production process. However, for large-scale production enterprises, how to process hundreds of bottles quickly and efficiently is a problem that cannot be ignored.

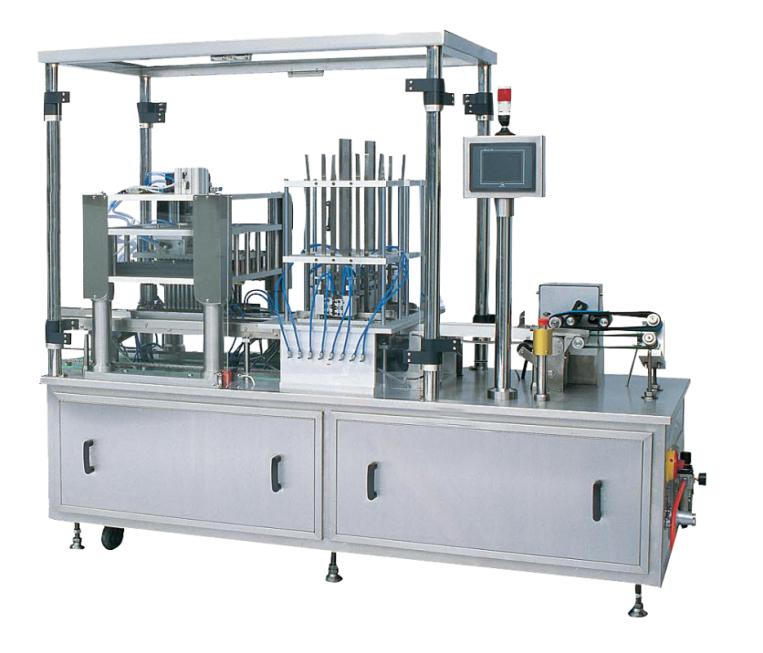

In order to solve this problem, we launched an intelligent automatic Tray Loading machine LFRT-40. The machine uses a robot for accurate positioning of the tray, and can automatically separate the non-breakable bottle tray materials. It is suitable for food, medicine and other industries. Let's take a closer look at the performance characteristics and related parameters of this machine.

First of all, with regard to its relevant parameters, the specification of the tray is 6 to 12 pieces per tray, and the tray loading speed is 30 trays/minute (related to the specification of the packaging material). At the same time, the size of the bottle is within the range of φ10~φ30mmx20~100mm(H), and the process of separating and placing can be completed automatically. In addition, the machine can automatically separate non-fragile bottle holder materials, which is suitable for many fields such as food industry and pharmaceutical industry.

Second, the machine has several performance features. First of all, the robot is used for accurate positioning and reliable performance, and will not cause damage to the bottle; secondly, it is equipped with a screw separation mechanism, which is fast in separation speed, accurate in positioning, and will not damage the bottle holder. In addition, German SEW motors and imported servo motors, frequency conversion stepless speed regulation, the whole machine runs more stably. The main material of the machine is 304 stainless steel, which meets the requirements of GMP and ensures the cleanliness and sanitation of the production environment. When replacing bottles with different diameters and bottle holders with different specifications, only the corresponding size parts need to be replaced, and the operation is simple and fast.

In addition, the machine is also equipped with a programmable logic controller (PLC), which can control the work more accurately. It can automatically stop and alarm when bottles are unscrambled, blocked, or lack of support according to the production situation. The machine also has a material buffer control mechanism to overcome the phenomenon of missing and wrong loading that is easy to occur when there is no support. The supporting position is completely open and easy to operate. Moreover, the bottle holders after bottling can directly enter the cartoning conveyor, fully realizing on-line automation.

Finally, the machine also has various safety devices to ensure the safety of the operation process. The whole machine runs smoothly, easy to operate, and convenient to maintain and repair. It can not only improve production efficiency, but also reduce errors and losses caused by manual operations. It is one of the important tools for enterprises to realize intelligent production.

In general, the automatic tray loading machine LFRT-40 has a number of excellent features, especially its accurate positioning of the robot tray, the configuration of screw splitting mechanism, programmable logic controller (PLC), etc., which can greatly improve the production efficiency of the enterprise, and at the same time Guarantee production quality and hygiene safety. We believe that in the near future, this equipment will become one of the indispensable automatic production equipment for enterprises in various industries, bringing more efficient, stable and accurate production experience to enterprises. We believe that in the future development, the automatic Tray Loading machine LFRT-40 will be widely used in all walks of life and make greater contributions to promoting intelligent manufacturing, realizing industrial upgrading and transformation and development.

pppharmapack is committed to creating the best intelligent equipment packaging machine, attaches great importance to the research and development, manufacturing, sales and service of our products, and becomes a booster of Industry 4.0. If you are interested in our company and looking for a precise and robust high-end device, please feel free to contact us.