Bottle unscrambler machine, as an important part of modern production lines, plays a vital role in bottling production lines in medicine, health products, food and other industries. The bottle unscrambler mainly improves production efficiency, reduces labor costs and ensures the smooth operation of the production line by sorting, sorting and transporting bottles. Below, the editor of Pharmapack will introduce you to the relevant knowledge of the bottle unscrambler in detail, including its definition, function, principle and the advantages of the Pharmapack bottle unscrambler.

1. What is a bottle unscrambler machine?

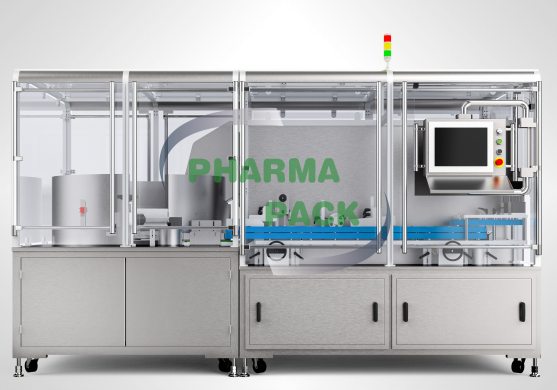

The bottle unscrambler is an automatic bottle unscrambler equipment specially designed for the pharmaceutical, health care products, food and other industries. It is mainly suitable for plastic bottle packaging lines in pharmaceutical, chemical, light industry, food, beverage and other industries. Through the bottle unscrambler, the messy stacked bottles can be sorted out and arranged on the conveyor belt in an orderly and directional manner, and then transferred to other machines at high speed and efficiency for the next process (such as filling, labeling, cartoning, etc.) , to improve the production efficiency of the entire production line.

2. What is the function of the bottle unscrambler machine?

The bottle unscrambler plays a vital role in the bottling production line, mainly as follows:

1. Improve production efficiency: The bottle unscrambler incorporates advanced motor technology, precision transmission mechanisms and complex control systems. The collaborative work of these components ensures that bottles can be positioned and arranged quickly and accurately during high-speed processing. The equipment is easy to operate and has a high level of automation, which significantly reduces manual dependence, effectively shortens the production cycle, and greatly improves production efficiency.

2. Reduce labor costs: Compared with the traditional manual bottle arrangement method, the improvement of the automation level of the fully automatic bottle unscrambler has greatly reduced the consumption of human resources. This transformation not only reduces labor intensity, but also reduces quality problems caused by improper manual operations, thereby significantly reducing labor costs.

3. Improve product quality: The fully automatic bottle unscrambler uses cutting-edge control systems and sensor technologies. These technologies can accurately identify various parameters of bottles, such as shape, size and position, to ensure the accuracy of bottle arrangement. This automated process greatly improves product consistency and quality.

4. Ensure production safety: The application of fully automatic bottle unscrambler greatly reduces manual intervention in the production process, thus improving production safety. In addition, its high degree of automation and simple operation further reduce operational risks and potential safety hazards, providing safety assurance for the production environment.

3. What is the principle of bottle unscrambler machine?

The principle of the bottle unscrambler mainly includes the following links:

1. Manually put materials into the storage bottle bin, and then the machine automatically feeds these materials to the turntable at a set speed.

2. The turntable rotates at high speed to feed the bottles at the speed required for production. Unsuitable bottles are removed by the Pulun mechanism to avoid material clogging.

3. The bottle dividing mechanism supplies bottles to the bottle unscrambler mechanism at a certain speed.

4. The bottle unscrambler mechanism transports the bottles to the exit conveyor working surface by clamping the conveyor belt, while the electrostatic dust removal mechanism removes dust inside the bottles.

5. The bottle turning mechanism corrects the inverted bottle and ensures that the bottle mouth is output upward.

6. Each process link of the machine is equipped with high-precision sensors for real-time detection and transmits signals to the electronic control system.

7. The electronic control system processes signals and controls the machine to perform various actions, such as stopping, starting, adjusting speed, rejecting defective products, fault alarm, etc., to achieve fully automatic operation.

4. Advantages of Pharmapack bottle unscrambler machine

Pharmapack bottle unscrambler has a high reputation in the market, and its advantages are mainly reflected in the following aspects:

1. Fully automatic and intelligent design: According to the production capacity requirements of subsequent processes, the bottle unscrambler speed is adjusted in real time without manual intervention.

2. Modular design: The bottle unscrambler turntable and the bottle unscrambler host are made into two parts that can be completely separated. They can be seamlessly connected during use and can be easily separated when not in use, saving space.

3. Adapt to multiple specifications and bottle shapes: The machine is mainly suitable for small bottle processing and can process up to 400 bottles per minute. This allows them to meet the needs of the most demanding bottle filling lines, including unscrambler cylinders, jars, oval, square, rectangular and other oddly shaped bottles.

4. The machine has excellent quality: the key parts are selected from internationally renowned brands and domestic first-line high-quality brands, which not only ensures the good reliability of the machine's operating functions, but also increases the service life of the key parts, and also provides high-quality products and services for the key parts of the machine.

Bottle unscramblers play an important role in modern manufacturing. The above editor of Pharmapack will help you understand the definition, function, principle and advantages of Pharmapack bottle unscrambler. I hope it can help us better apply it in production practice, reduce costs and increase efficiency for enterprises, and improve production. profit. For more information on bottle unscramblers or pharmaceutical packaging machines, please visit the official website of Pharmapack.