Case packing machines play a pivotal role across many industries where efficiency reigns supreme. A top case packer machine streamlines operations and meets the demands of modern manufacturing while promising product integrity during shipping and distribution.

It leads to inevitable second thoughts when considering diverse options. To help you make an informed decision, we've compiled the top 3 questions you should figure out before investing in case packer equipment.

Q1: What types of case packing machines do you need?

Case packing machines come in various types, each designed with unique strengths. For instance, depending on the packing direction, case packer machines can be divided into vertical and horizontal case packer machines. The former is ideal for applications where space is limited, while the latter is well-suited for handling larger products or those that require gentle handling.

Other key considerations include the machine's maximum output capacity, flexibility in handling various case sizes and packaging configurations, and more. Check features that ensure accuracy and precision, like advanced sensors, vision systems, or robotics.

Q2: Is the machine easy to set up, operate, and troubleshoot? Any maintenance requirements?

The above factors can assist you in narrowing down suitable case packing machines, and subsequently, you can refine your choices based on post-purchase operational factors. Overall, 5 main aspects require your consideration.

lUser-Friendly Controls and Interfaces:

Clear and simple controls make it easier for operators to set up the case packer machine, adjust settings, and monitor performance. At the same time, the intuitive interfaces can provide visual feedback and easy access to critical functions that can significantly enhance productivity and reduce error risks.

lRemote Monitoring and Diagnostics:

It would be better if the case packer equipment come with remote monitoring capabilities as remote access to machine data and diagnostics enables timely troubleshooting, minimizing downtime and maximizing uptime. This feature is precious for distributed or unmanned production facilities.

lTool-Less Changeovers:

Tool-less changeovers allow operators to quickly and easily switch between different packaging formats or product configurations without requiring specialized tools or extensive downtime. It enhances flexibility and efficiency, enabling you to adapt to changing production requirements with minimal disruption.

lMaintenance Requirements:

It helps to take into account the case packing machine's maintenance demands, including lubrication schedules, part replacements, and preventive maintenance tasks. Go for a case packer machine with straightforward maintenance procedures and easy access to critical components. They help minimize the time required for solving potential issues.

lTraining and Support:

The optimal user experience with the case packing machine also demands training support from the supplier or manufacturer. Proper training for operators and maintenance staff is essential for maximizing the machine's performance and longevity. Therefore, a supplier that offers training programs, technical support, or readily available documentation to assist with setup, operation, and troubleshooting is your ideal partner.

Q3: What are the initial investment and ongoing operational costs?

The last question you should figure out for your ultimate case packing machine is the costs before and after adoption to determine its long-term value and return on investment (ROI). Your consideration can start with factors including expected lifespan, energy consumption, consumables, and maintenance expenses.

To conclude, a case packer machine with energy-efficient features, low maintenance requirements, and high reliability can minimize ongoing costs and maximize production efficiency, contributing to your company's profitability and competitiveness in the market.

What Pharmapack Has for You?

After figuring out the above 3 questions, you can better understand what you genuinely need. With a focus on client demands, Pharmapack is committed to developing top automatic packing machines, among which case packing machines shine.

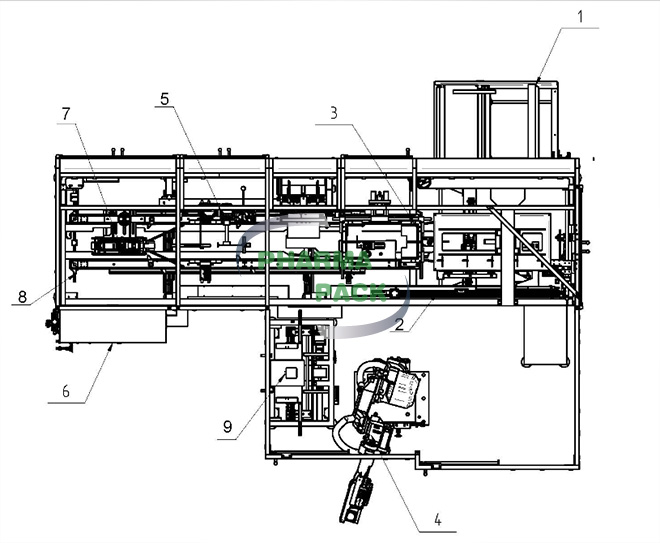

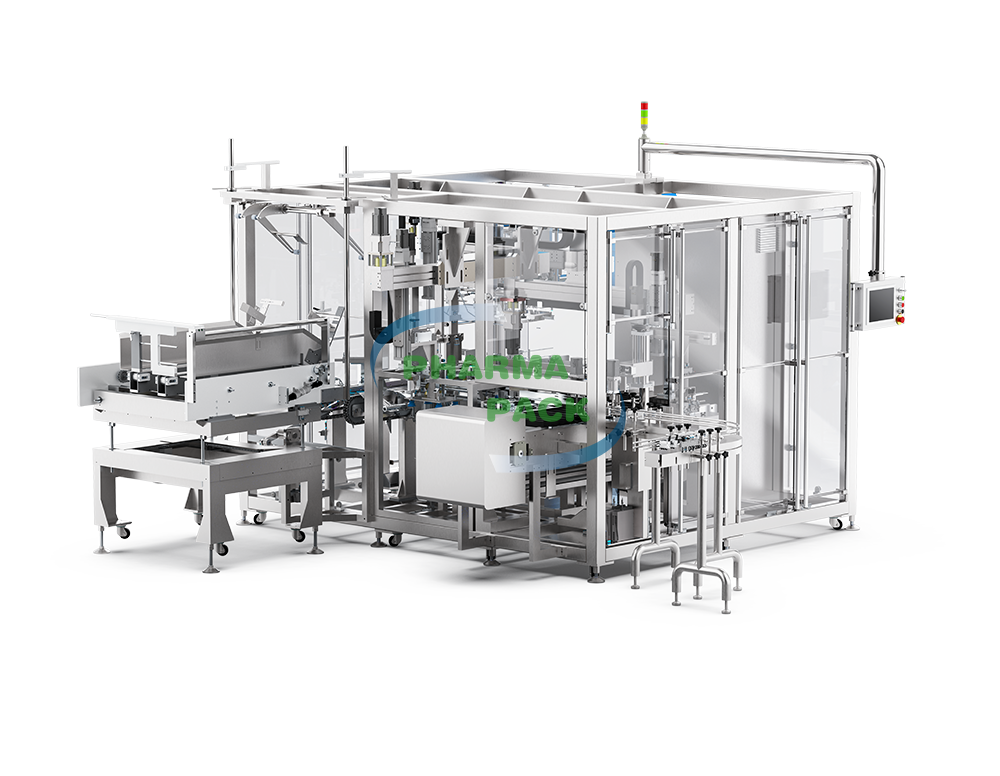

From the LFCI-04 Automatic Case Packer that can handle 20 cases per minute maximum to the ALFC-04S Automatic Case Packer with a robot arm, our case packer solutions are well-designed models that excel in quality assurance, user-friendliness, adaptability, and maintenance requirements. More possibilities are achievable with customized options.

Conclusion

Selecting the perfect case packing machine requires careful consideration. The 3 questions proposed above may save you time on decision-making as they encompass factors to consider before and after purchase. As a one-stop solution supplier, Pharmapack offers services including design, commissioning, maintenance, and upgrades.

With 400+ patents and 1500+ application line cases, we have much to satisfy your needs for automatic packing machines, ranging from pharmaceutical packaging equipment to cosmetics packing equipment. Contact us to convey your needs; we are well-prepared to solve your other problems.