How could you tell pure water from saltwater between two glasses of clear water without tasting them? Yes, from the labels attached to the glasses! The labels' significance can be even greater when they are applied to pharmaceutical products, food, and cosmetics, as they are the cornerstone of product identification, traceability, and overall brand integrity.

The fast-paced landscape has called for the automatic labeler machine, which offers unmatched precision, speed, and consistency. So, which automatic labeling machines should you invest in? This article will explore their different types to help you make an informed decision.

Different Types of Automatic Labeler Machines

1. According to the Position of Label Attachment

l Flat Labeling Machine

These automated labeling machines are designed to apply labels onto flat surfaces such as boxes, cartons, or envelopes with pinpoint accuracy and consistency. They can utilize advanced labeling mechanisms such as tamp, wipe-on, or blow-on applicators to ensure seamless label adhesion, even on irregular surfaces.

l Side Labeling Machine

Meanwhile, side labelers affix labels onto the sides of products or packaging. These automatic labeler machines can be further divided into different types based on which specific side they attach labels to, such as front & back labeling machines and top side & bottom side labeling machines. You may have some of our existing side labeling machines for better understanding.

Specs Models | LFLB-3220 Front & Back Labeler | LFLB-4220 Top side & bottom side labeling machine | LFLB-3120TS Side, circumferential turning labeling machine |

Max Output | 200 bpm | 200 bpm | 200 bpm for round bottle; 80 bpm for square/rectangle bottle |

Labeling Accuracy | ±1.0 mm | ±1.0mm | ±1.5 mm |

Supported Subject | Bottle | Container (Width:50-120mm) | Round bottle: φ10-φ80, H≥6mm, square bottle: 150*150mm |

l Corner Labeling Machine

Corner labeling machines can be a good choice for improved space utilization. They apply labels on the corners of products or packaging, maximizing branding opportunities and aesthetic appeal. Moreover, corner labeling can be employed for anti-disassembly purposes.

l Wrap-around Labeling Machine

For those seeking 360-degree coverage on products or packaging, wrap-around labeling machines are your ideal solution. These automatic labeler machines are suitable for wrapping labels around cylindrical objects such as bottles, cans, or jars, ensuring that ample information is visible from all angles. Here at Pharmapack, you can utilize our high-speed wrap-around & top labeler to increase efficiency.

2. According to the Container's Positioning

l Vertical Labeling Machine

Vertical labeling machines are for containers that can be positioned upright, such as beverage bottles, food jars, and pharmaceutical bottles. They are the perfect labeling machine for bottles, like cylindrical bottles and square bottles.

l Horizontal Labeling Machine

Bottles that cannot stand upright stably had better go through horizontal labeling machines, which enable bottles to be labeled by lying on their sides. For instance, bottles or vials with curved bases can rely on horizontal labeling machines for effective labeling.

Take two of Pharmapack's automatic labeling machines for illustration. You can grasp some key factors through the graph below.

Specs Models | LFLB-1120F Vertical rectangular bottle and round bottle labeling machine | LFLB-2240 Horizontal round bottle labeler |

Max Speed | 200/80 bpm | 400 bpm |

Container Size | Round bottle: L:Φ20mm~Φ90mm H:60~400mm; Square bottle:L:20~60mm H:60~400mm; Rectangular bottle: L:20~90mm H:60~400mm | φ10mm-φ30mm H:10-130mm |

Label Accuracy | ±1.5 mm | ±0.5 mm |

Highlights | Versatile applicability (across different bottle sizes and types) | Specifically for small round bottles (such as ampoules and syringes) |

3. According to the Direction of Product Movement

l Inline Labeling Machine

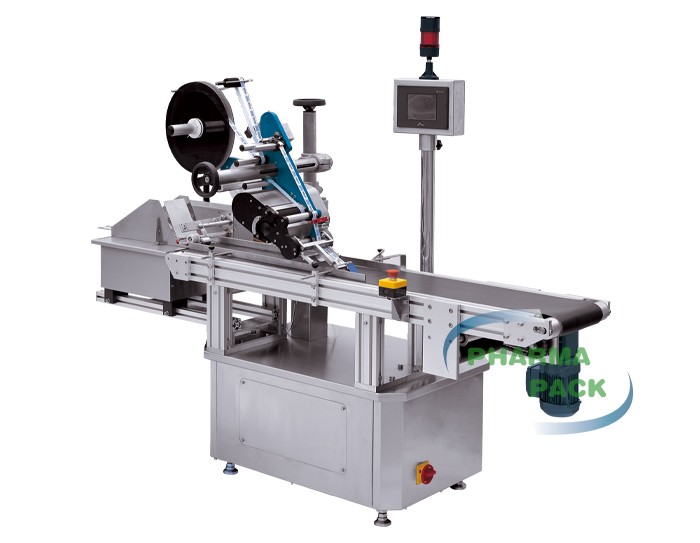

Inline labeling machines label products in a linear way as they move along a conveyor belt. These automatic labeler machines boast high speed, precision, and versatile applications, making them cost-effective options for simple applications.

l Rotary Labeling Machine

Regarding rotary labeling machines, they label products arranged in a circular or rotary manner. The bottles are sorted and transferred to a turret, where each bottle is securely held between a bottom plate and a top centering bell. You can rely on rotary labeling machines for more complex and higher-speed label applications, just as demonstrated by the examples of our products below:

Specs Models | LFLBR-124032 Rotary round bottle labeler | LFLB-1160R Rotary vertical round bottle labeling machine |

Max Output | 300 bpm | 600 bpm |

Container Size | Φ35mm-80mm H:60-150mm | φ8mm-φ30 mm |

Label Accuracy | ±1mm | ±0.5 mm |

Highlights | Double headers for quick labeling, double UV detection & automated rejection for precision | Perfect for different vials, including ampoule, antibiotic, and oral syrup |

Pharmapack- Where You Can Explore for Your Perfect Automatic Labeler Machines

Here at Pharmapack, we offer diverse automatic labeling machines that meet the unique needs and regulatory requirements of different industries, especially automatic bottle labeling machines for the pharmaceutical sector. Our top automated labeling machines come with strengths like:

l Precision Engineering: They utilize advanced technology, like servo-driven labeling heads, to ensure that labels are applied with millimeter-level accuracy, even on challenging surfaces or irregularly shaped containers.

l Compliance Assurance: Adhering to international standards like GMP, these automated labeling machines can offer you peace of mind in achieving compliance with stringent regulatory requirements such as serialization, tamper-evident labeling, and barcoding standards.

l Versatility and Flexibility: Our automatic labeler machines accommodate a wide range of labeling applications, container sizes, and production volumes. Also, they come in customizable options that can be tailored to address your needs.

l Reliability and Efficiency: With robust construction, durable components, and advanced automation features, these labeling machines minimize downtime and maximize throughput, ensuring continuous operation and optimized production efficiency.

Conclusion

To conclude, we've explored different types of automatic labeler machines from 3 perspectives. If you are interested in any of them or looking for more, feel free to contact us. Our professional team members will always be there.

You can rely on us for top packaging machines, especially pharmaceutical packaging equipment. With 20+ years of experience, Pharmapack has a comprehensive product catalog covering a complete packaging line. Paired with our professional custom services, we have garnered worldwide trust, including that of some global brands like Pfizer and Baxter.