The Ultimate Guide to Understanding Powder Packaging Machines

Powder packaging machine is a kind of mechanical equipment specially

used for packaging powdered products.

It has a wide range of

applications and can be used in many industries such as the food

industry, the chemical industry, the pharmaceutical industry, etc. This

article will give you a detailed introduction to the types,

characteristics, scope of application, and maintenance methods of powder

packaging machines to help you better understand and use them.

Types of Powder Packaging Machines

The

classification of powder packaging machines is mainly based on their

working principle, packaging form, and technical characteristics.

According to different classification standards, powder packaging

machines can be of the following types:- Classification according

to the working principle: volumetric powder packaging machines and

gravimetric powder packaging machines.

- Classified by packaging

form: vertical powder packaging machines, pillow-type powder packaging

machines, and box-type powder packaging machines.

- Classification

according to the degree of automation: semi-automatic powder packaging

machines and fully automatic powder packaging machines.

Classification

according to the characteristics of packaging materials: ordinary

powder packaging machines and moisture-proof powder packaging machines.

Characteristics of Powder Packaging Machines

The

powder packaging machine is a comprehensive machine that integrates

machinery, electricity, lighting, and instrumentation. It is controlled

by a single-chip microcomputer and has functions such as automatic

quantification, automatic filling, and automatic adjustment of

measurement errors. Its advantages include fast speed, high precision, a

wide packaging range, a wide application range, fully automatic

control, automatic quantification, and easy cleaning.

Application Scope of Powder Packaging Machines

Powder

packaging machines can be used in various fields and industries such as

the food industry, the pharmaceutical industry, the chemical industry,

and the metallurgical industry to package various powders and granules

with certain fluidity.

Maintenance Methods of Powder Packaging Machines

Maintaining

powder packaging machines is a systematic process involving many

aspects. Firstly, daily cleaning is essential, including timely removal

of residual powder after use and regular deep cleaning of key components

such as metering devices and sealing mechanisms. Secondly, regularly

add lubricating oil to moving parts to reduce wear and ensure smooth

operation of the equipment. In addition, various functions of the

equipment, such as weighing accuracy and sealing tightness, as well as

the stability of the conveyor belt, are regularly checked to ensure that

problems are discovered and solved in a timely manner. Finally, keep

the working environment where the equipment is located dry and clean to

avoid excessive moisture and dust from affecting equipment performance.

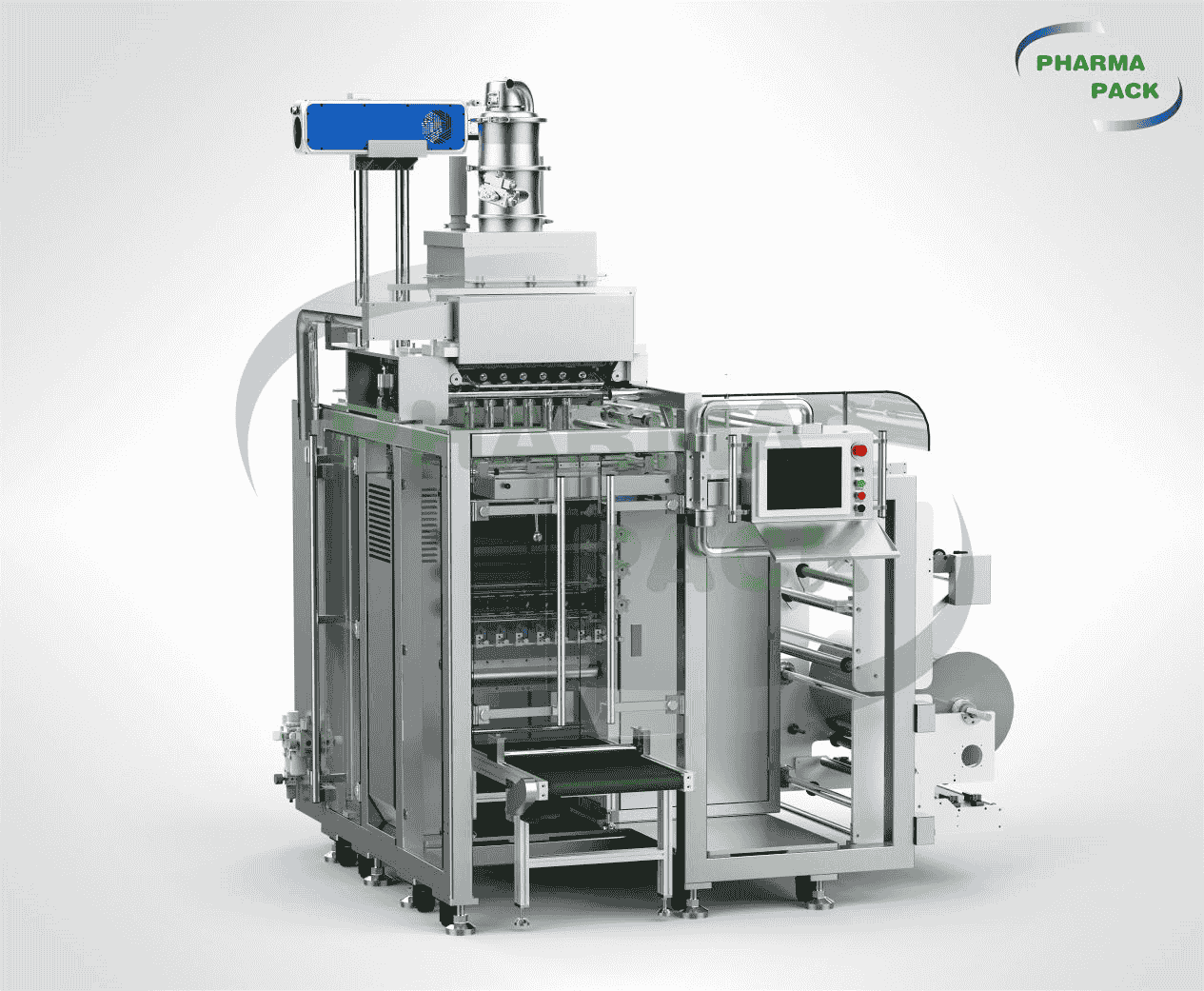

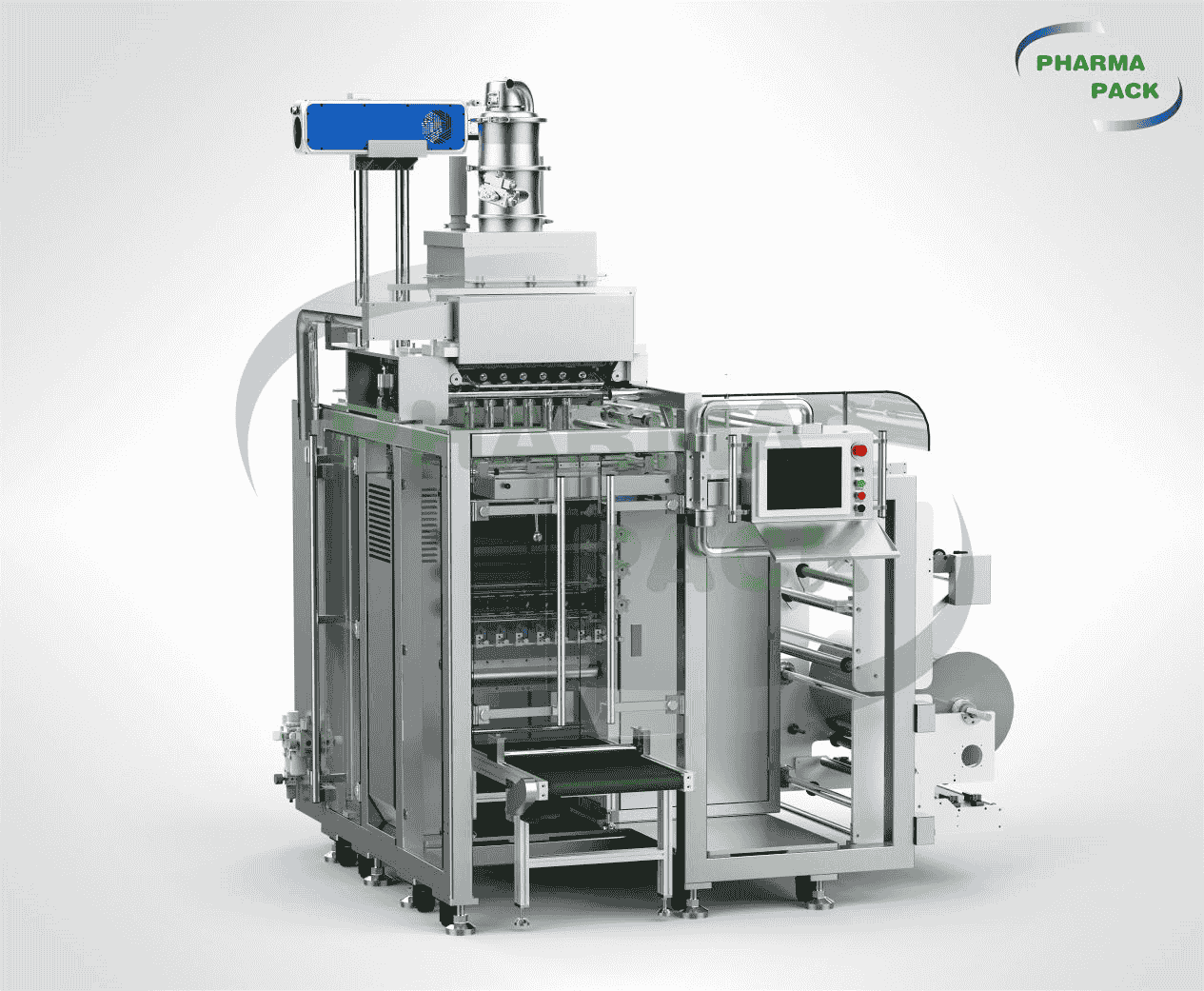

The pppharmapack Powder Packaging Machine: LFB-6H

The pppharmapack powder packaging machine LFB-6H has the following features:- Maximum production speed: 60 cuts/minute.

- Automatic

bag making, filling, sealing, slitting, notch cutting, vertical and

horizontal cutting, information printing, packaging, and other

functions.

- The control system adopts internationally renowned brand servo motors to ensure precise operation.

Summarize:

Powder

packaging machines are very important mechanical equipment suitable for

many industries and fields. Understanding the types, characteristics,

scope of application, and maintenance methods of powder packaging

machines will help us better use and maintain them, improving production

efficiency and product quality.