What is an automatic palletizer?

In industrial production, placing products or goods on pallets is a time-consuming and expensive task. This not only puts pressure on the workers' bodies but also reduces production efficiency. In order to solve this problem, automatic palletizing machines were developed.

An automatic palletizer is a machine that can automatically sort, transfer, and stack goods or products onto pallets. They are usually located at the end of the production line and can effectively improve transportation efficiency, reduce labor costs, and relieve the burden on workers.

Types of palletizers

Palletizers can be classified into the following types according to different standards:

1.Classified by intelligence level

·Robot palletizers: Using advanced control technology, they can achieve high precision and high-efficiency palletizing operations.

·Mechanical palletizers: including gantry type palletizers, column type palletizers, mechanical arm type palletizers, etc. They have a simple structure and are easy to maintain.

2.By industry

·Food and beverage industry palletizers: suitable for the special needs of food, beverage, and other industries, such as moisture-proof and anti-corrosion requirements.

·Cement automatic loading and palletizing machines: used for automatic loading and palletizing of cement and other powdery materials.

·Industrial palletizing machines: suitable for palletizing various industrial products.

3.Scored by degree of automation

·Manual palletizers: require manual operation and are suitable for small enterprises or short-cycle production tasks.

·Semi-automatic palletizers: require partial manual intervention and are suitable for medium-sized enterprises.

·Fully automatic palletizers: Highly automated and suitable for large enterprises or continuous production modes.

Different types of palletizers are suitable for different working environments and needs. When choosing a palletizer, it is necessary to consider factors such as palletizing capacity, applicable material type, stacking method, mechanical size and weight, energy consumption, and maintenance requirements.

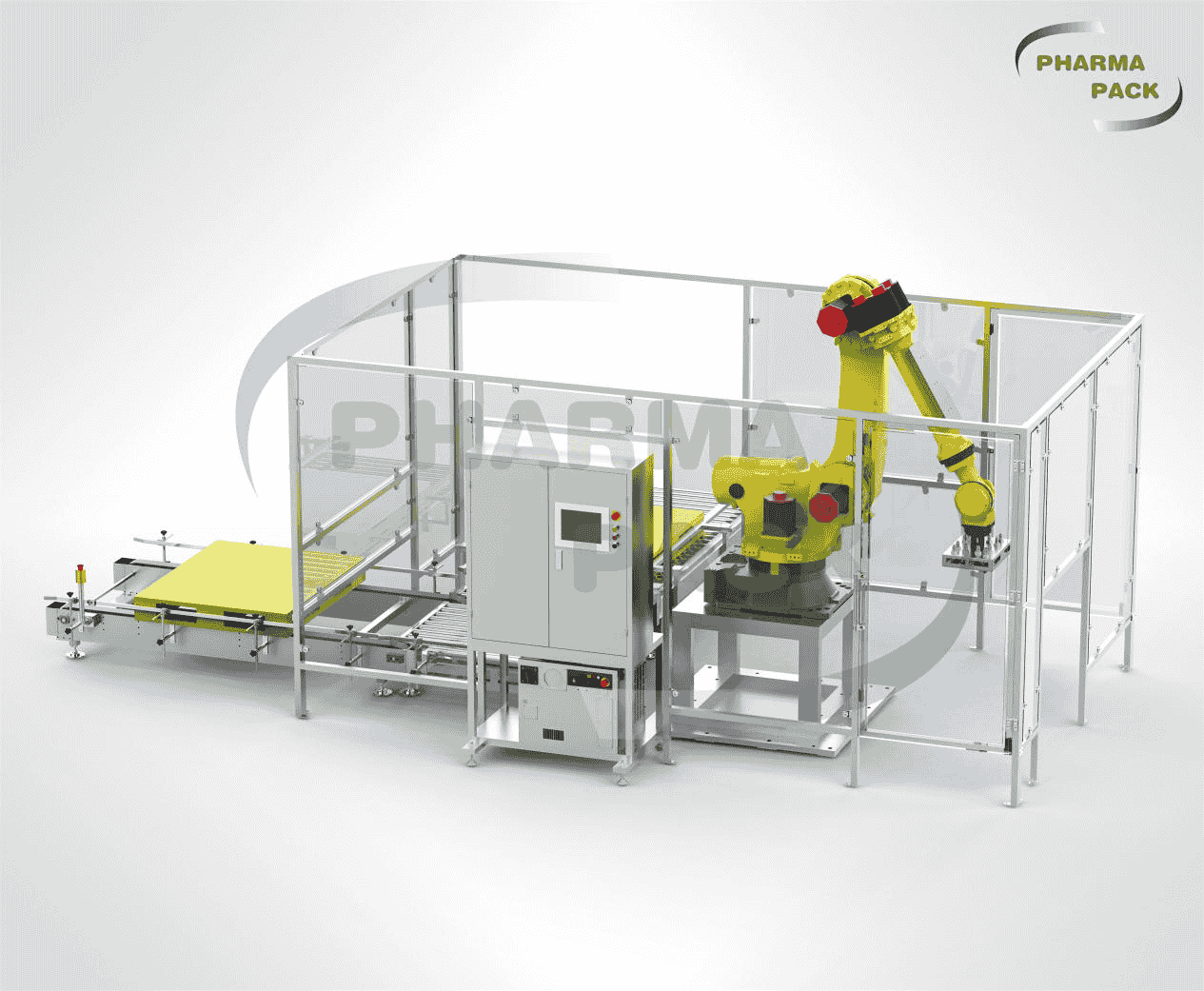

Advantages of pppharmapack automatic palletizer ALFC-40

pppharmapack automatic palletizer ALFC-40 is highly regarded in the market for its excellent performance and efficient operation. Its advantages are mainly reflected in the following aspects:

1.Robot arm design

The robot arm adopts a vacuum adsorption or clamping device, which can be designed according to carton specifications and palletizing requirements, improving the flexibility and adaptability of palletizing.

2.Palletizing part adopts an automatic conveying device

The palletizing part adopts an automatic conveying device, which can transport the palletizing plate to the palletizing position. When the A palletizing plate is completed, it is automatically transported to the exit, and the B palletizing plate is automatically transported to the palletizing position; It can also use a double palletizing board, when A palletizing board is completed, the robot automatically palletizes board B palletizing board, and the operator can at the same time palletize A palletizing board fork out without affecting production.

3.Strong and beautiful frame

The frame is welded with carbon steel profiles, making it strong and durable. It also features an aluminum profile, giving it an overall beautiful and generous appearance.

4.Imported electrical components

The whole machine adopts imported electrical components, ensuring stable and durable quality, high safety performance, and a humanized man-machine interface. It provides simple and convenient operation, with self-protection and fault display functions, equipment fault automatic warning alarm, and display alarm information.

In short, automatic palletizing machines are important equipment to improve industrial production efficiency and reduce labor costs. With the continuous development of science and technology, automatic palletizing machines will play an increasingly important role in future industrial production.