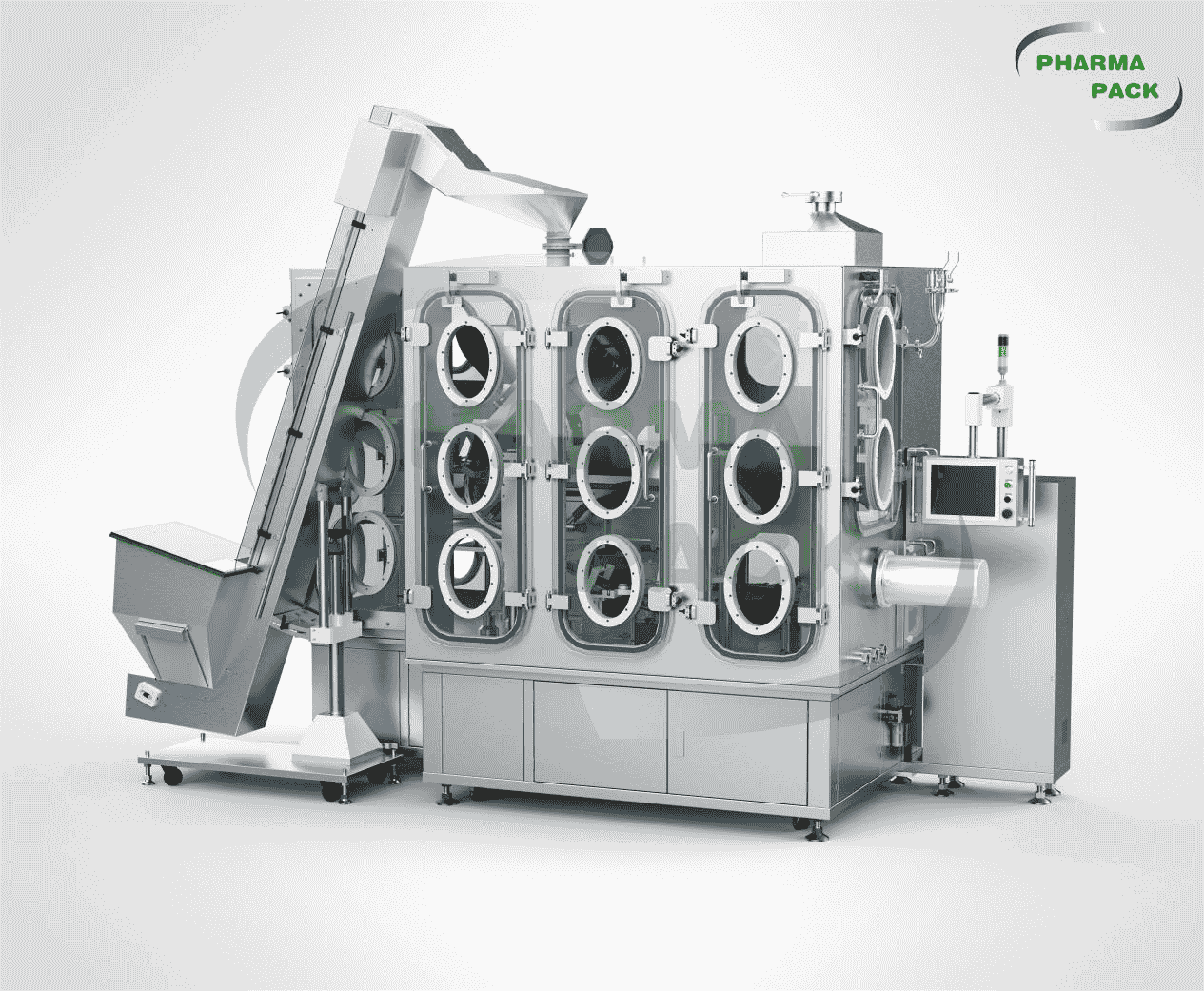

Safety Enhancement in Pharmaceutical Packaging: The Crucial Role of the Integrated Pill Counting and Capping Machine LF-0601C

In the field of pharmaceutical production, some operators need to be

in direct contact with drugs. If the drugs are toxic or corrosive, they

pose a serious threat to the safety of the operators. Therefore, to

ensure the safety of the operators and the quality of the drugs, a safe

and non-toxic system is established. Creating a safe working environment

requires consideration of many factors, including equipment selection,

process optimization, and operator training. Among these factors,

equipment selection is particularly critical. Safe and high-quality

automation equipment is a powerful tool for improving the efficiency of

modern production lines.

How to Ensure the Safety of the Integrated Pill Counting and Capping Machine LF-0601C

The

all-in-one counting and capping machine LF-0601C is specially designed

for pharmaceutical packaging. It utilizes negative pressure in the

working space generated by the sterile isolation cover and exhaust

system to block external contamination and avoid contact with the

operator. It is suitable for professional multi-grain packaging of

easily contaminated, moisture-prone, toxic, and corrosive drugs.

Performance Advantages of the Integrated Grain Counting and Capping Machine LF-0601C

Material and Structural Safety

- Wide Applicability: Suitable for soft, hard, and transparent capsules, tablets, pills, and other solid pharmaceutical granules.

- Lid Compatibility: Suitable for rotating threaded lids and anti-theft lids.

- Material

Safety: Designed in accordance with GMP standards, the parts in contact

with drugs are made of AISI 316L stainless steel, and the body cover is

made of AISI 304 stainless steel.

- Structural Fastening: All

electrical control and other parts are sealed to prevent drug powder

from affecting the service life of electrical components.

Easy Operation and Maintenance

- Easy

Operation: Control the pneumatic device to lock or loosen the vibration

plate through the touch screen, no tools are required to disassemble.

- Easy Maintenance: It adopts an embedded buckle structure, which is easy to disassemble, clean, and maintain.

Intelligent Detection and Automation

- Intelligent Detection: Automatic detection of no bottle or inverted bottle, automatic alarm.

- High

Degree of Automation: During the normal production process, no special

personnel is required to supervise, and it is equipped with various

self-protection devices.

- Reduce Labor Intensity: Automatic cap removal and screwing reduces the operator’s labor intensity.

High-Quality Components and Efficient Bottling

- High-Quality

Components: A full set of Festo and SMC pneumatic parts, and the main

motor adopts German SEW variable frequency speed regulating motor to

ensure accurate and uniform movement.

- Efficient Bottling: 12 tracks simultaneously load the single vibrating feed nozzle, resulting in fast bottling speed.

- Precise Granule Dispensing and Exit Detection

- Precise

Granule Dispensing: Using a vibrating granulation mechanism, when the

granules are filled, the blanking nozzle will firmly cover the bottle

mouth, ensuring that large granules are bottled without blocking the

material, and small granules are bottled without material falling, which

is helpful for solving the problem of bottle mouth material blocking

effect is significant.

- Exit Detection: The outlet has a capping detection function, and caps with poor capping will be rejected.

The

Pharmapack all-in-one capsule counting and capping machine LF-0601C not

only has excellent equipment performance, but its operating system and

processor also adopt advanced foreign imports, ensuring quality.

- High-Speed

Electronic Digital Chip Technology: Introducing mature high-speed

electronic digital chip technology from well-known foreign

manufacturers, based on high-speed microprocessor (MCU) technology and

equipped with an operating system with full Chinese dynamic graphics

display. Parameters can be set on the touch screen setting interface.

- High-Configuration Processor: Using the German INFION C165 MCU processor, which has the highest configuration in the industry.

- Automatic

Fault Diagnosis and Real-Time Monitoring: Automatic fault diagnosis and

real-time monitoring alarm display system, and can store 100 sets of

product parameters, which can be called directly when replacing

products.

- Intelligent Adjustment: When changing bottles of

different heights, it is easy to adjust and can be operated on the touch

screen to automatically adjust the height of the whole machine.

In

general, a safe working environment in the pharmaceutical packaging

industry is crucial, and the integrated capsule counting and capping

machine LF-0601C provides operators with a safe and efficient working

environment through its advanced design and functions.