In the field of powder filling, companies face many challenges, the most critical of which is to select the right powder filling equipment for a specific application. In order to meet financial goals and customer expectations, companies need to find the right bottling solution to maximize the return on investment. To help packers choose the right powder filling machine, we have produced this guide.

Powder filling machines are highly efficient automated equipment, mainly used to automatically fill powder or small particulate matter into containers. They are widely used in packaging powder, small granule medicine, milk powder, veterinary medicine, condiments, powdered granular additives, glucose, solid drinks, talcum powder, pesticides, and other products.

The operation process of a powder filling machine

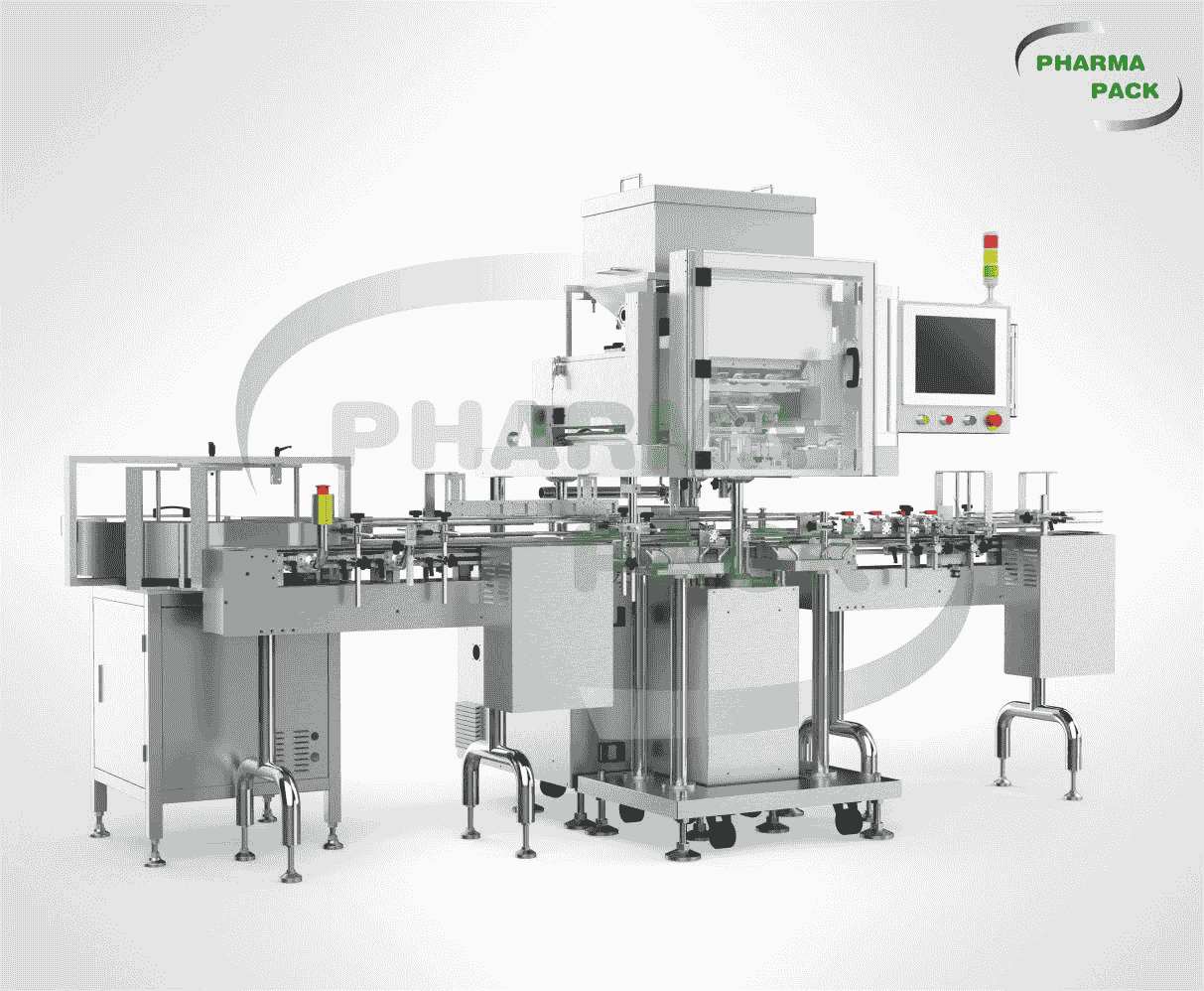

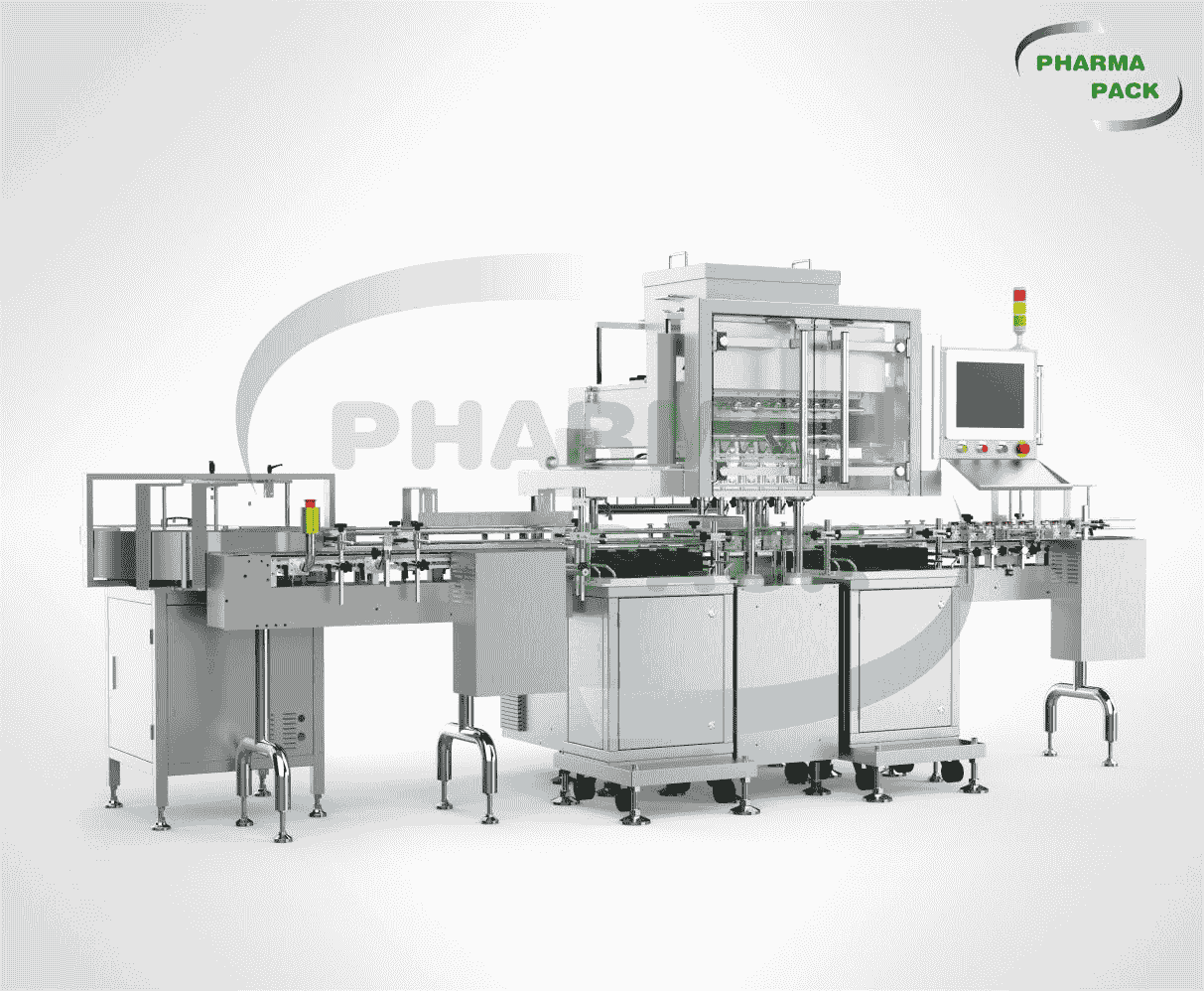

The powder filling machine is not only suitable for drugs, health products, and other industries, but is also widely used in the food, cosmetics, chemical, and other industries. According to different products and needs, the filling speed and filling amount can be adjusted to meet various production needs. At the same time, it can also be combined with other packaging equipment, such as sealing machines, label machines, and other equipment to form automated production lines.

1. The powder is added to the bin through the feeding machine, and the blender in the bin will mix the powder well to ensure the uniformity and stability of the powder.

2. The powder is measured by the screw and enters the blanking port. According to different equipment, the number of blanking ports is also different, usually there are 2 to 4 blanking ports for improving production efficiency.

3. The bottle is transported to the filling position by the feeding screw, and the powder is filled into the bottle after the blanking mouth is placed over the bottle mouth. After filling is complete, the blanking port is moved up and the bottle is transferred to the next process.

① All stainless steel structure, combined transparent material box, no tools, easy to disassemble and wash.

② High precision servo motor control filling, accurate measurement.

③ Various product adjustment parameter formulations can be stored for later use, up to 30 process parameter formulations can be stored.

④ Screw positioning into the bottle, accurate positioning.

⑤ Touch screen PLC control, no bottle does not fill, the machine remains in standby state.

The equipment contact material part is made of 304 stainless steel, and the motor, cylinder, electrical accessories, pneumatic components, and other well-known brands are selected.

The device is composed of PLC, touch screen, and other control core, which maximizes the control accuracy and stability of the machine.

1. LFFM-0202WR

Applicable industries: food, chemical, medicine, health products, and other industries.

Applicable products: Suitable for all kinds of plastic bottle packaging powder or small particle products, such as milk powder, glucose, solid drinks, veterinary drugs, etc.

Filling capacity: 10 ~ 50g, can be adjusted according to actual demand.

Maximum speed: 30 bottles/min, depending on the viscosity of the powder and filling volume.

Features: compact structure, easy operation, high measurement accuracy, suitable for medium production needs.

2. LFFM-1006WR

Applicable industries: cosmetics, fine chemicals, pharmaceuticals, and other industries.

Applicable products: Suitable for powder or small particle products packaged in small-capacity plastic bottles, such as talcum powder, cosmetic raw materials, capsule fillers, etc.

Filling capacity: 10 ~ 50g, providing high precision metering control.

Maximum speed: 100 bottles/min, suitable for high-efficiency production lines.

Features: High speed and high efficiency, suitable for mass production, with the ability to quickly change product specifications.

3. LFFM-0604

Applicable industries: food, medicine, health care products, chemical industry, etc.

Applicable products: Suitable for a variety of plastic bottle packaging powder or small particle products, such as condiments, powder additives, pesticides, etc.

Filling capacity: 10 ~ 50g, providing a wide range of measurement.

Maximum speed: 60 bottles/min for high yield requirements.

Features: strong flexibility, suitable for a variety of specifications of product filling, easy to maintain and clean.

Having a good understanding of the different aspects of powder filling machines can help you determine which machine is best for your application. Machines are a big investment, so you need to make sure you buy the right machine to avoid any incompatibility issues in the long run.

Fortunately, choose a powder filling machine manufacturer that provides consulting services throughout the entire process of machine customization. This guarantees that you will get a machine that is perfectly suited to the specific needs of your business. If you need help with packaging solutions, please feel free to contact us, one of the leading packaging machine manufacturers in China. Pharmapack is happy to help you.