With the increasing attention of consumers to packaging quality, round bottle labeling has become a basic requirement of the pharmaceutical industry. Manual labeling has been unable to meet the efficient and accurate needs of mass production. Therefore, an automatic labeling machine has become a key equipment for enterprises to improve production efficiency, reduce costs, and ensure product consistency. This article will introduce you to the LFLB-1120 vertical round bottle labeling machine, which will provide you with a new labeling experience.

The LFLB-1120 vertical round bottle labeling machine is an indispensable automation equipment in the pharmaceutical industry. It is mainly used for the automatic labeling of the cylinder of round bottles, ensuring the accuracy of product identification and the improvement of production efficiency. The device has the following functions:

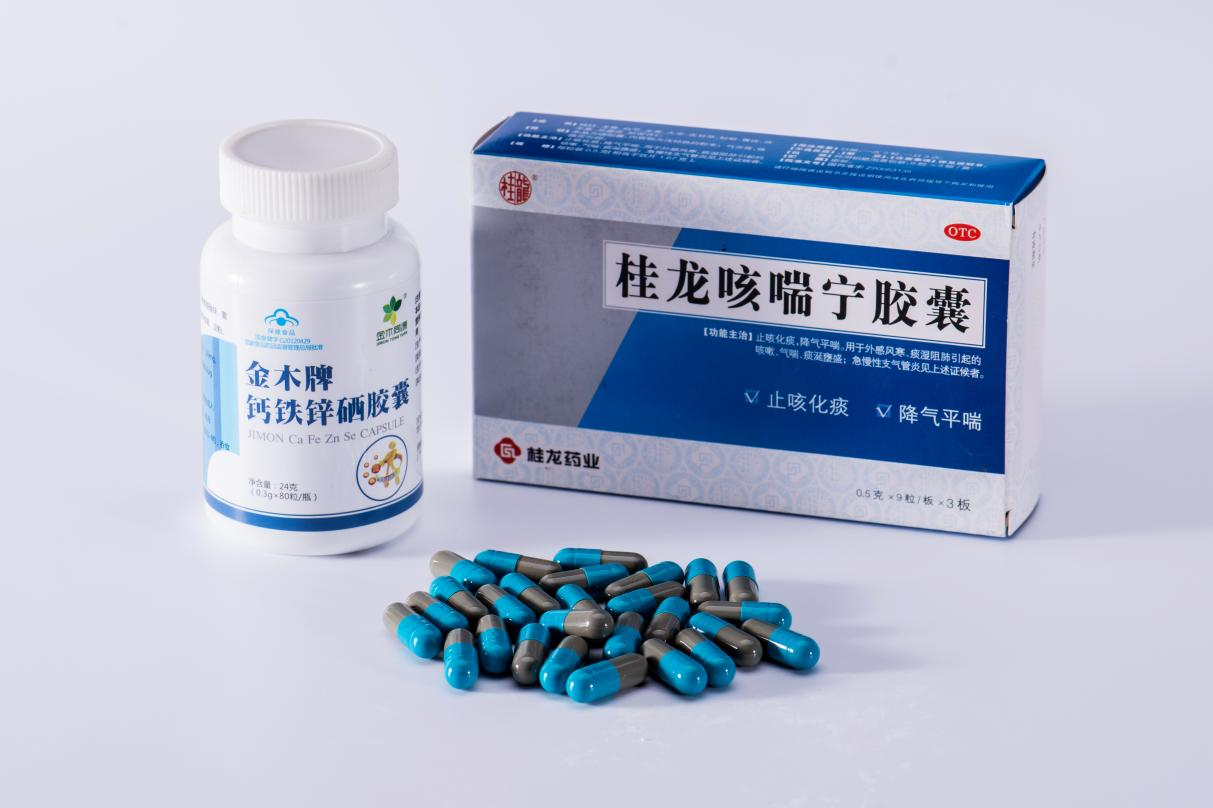

1. Automatic Labeling: The vertical round bottle labeling machine will automatically paste the label to the cylindrical surface of the round bottle. It is suitable for a variety of drug packaging, such as xylin bottles, ampoules, and oral liquid bottles, to ensure the consistency and accuracy of label placement.

2. Accurate Labeling: In the pharmaceutical industry, accurate labeling and information are the guarantee of product quality and safety. The vertical round bottle labeling machine ensures that the label content is clear and readable through accurate labeling operations, thus improving the overall quality of the product.

3. Production Efficiency and Cost Savings: The automated labeling process reduces manual operation, significantly improves production efficiency, and reduces labor costs and material waste, bringing economic benefits to the enterprise.

4. Integration with Other Equipment: The vertical round bottle labeling machine can be used in combination with the printing machine to realize the printing of the label at the same time, further improving the production efficiency and instant management of product information.

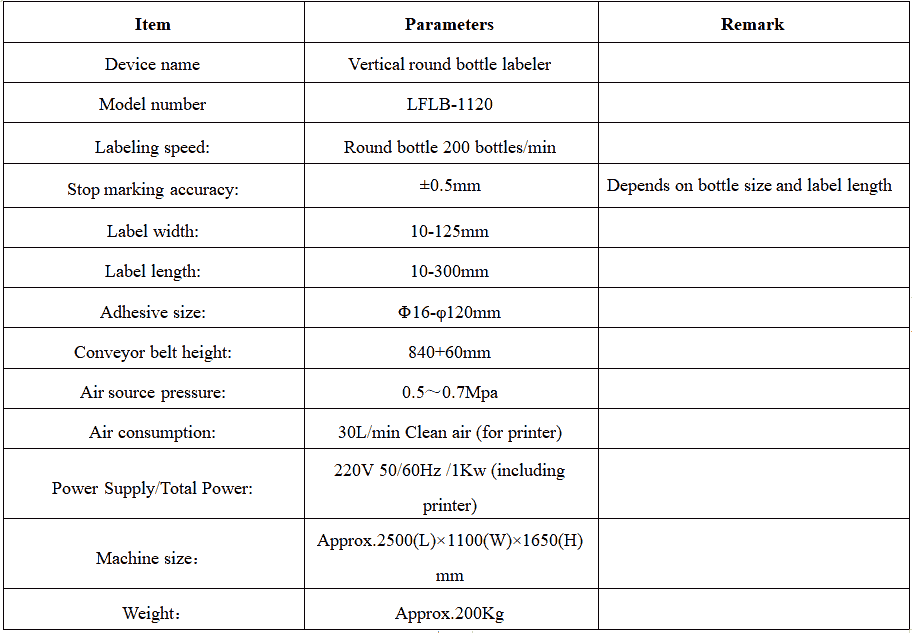

1. High Precision: The servo motor closed-loop control technology is used to achieve a high precision stop mark of ±0.5mm to ensure that the label position of each bottle is accurate.

2. High Efficiency: Labeling speed is up to 200 bottles/min, to meet the needs of mass production.

3. Wide Range of Application: Suitable for round bottles with a diameter of 16-120mm, the label width range is 10-125mm, and the length is 10-300mm.

4. Humanized Design: The operation is intuitive and simple, with parameter storage, label counting, fault warning, and other functions, making the operation more convenient.

5. Flexible Configuration: It can be equipped with a hot belt printing machine to realize the printing of product date and batch number. Optional color standard electric eye, UV electric eye, bar code detection system, etc., to meet the detection needs of different products.

6. High-Quality Material: The body is made of stainless steel, durable, and fully in line with GMP requirements.

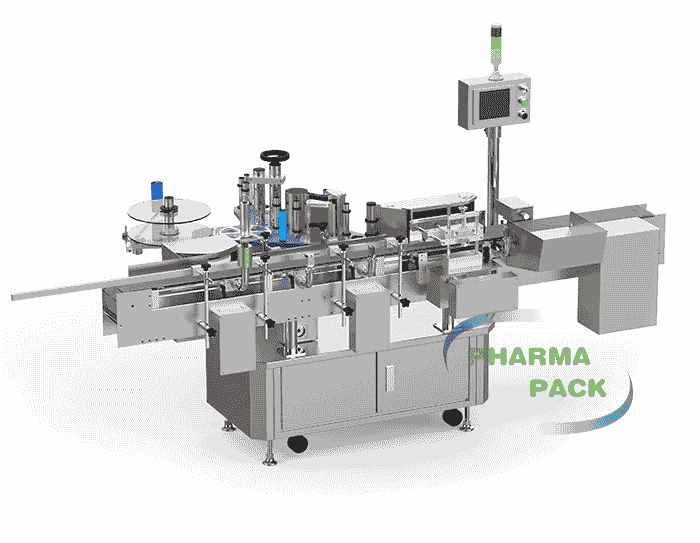

The labeled bottles enter the conveyor belt and are arranged at a certain distance after being divided by the parting wheel and transported forward by the conveyor belt. When it reaches the measuring object electric eye, the measuring object electric eye senses the bottle and sends out the mark signal to the marking device immediately. The bottle is labeled at the place where it passes through the marking board. At the same time, the bottle winding belt rotates the bottle and affixes the label roll to the bottle circumference surface, and the bottom paper is rolled back. When the marking eye detects the end of the label, it sends a stop marking signal to the marking transmitter to complete the labeling.

1. The system is controlled by a microcomputer, and the touch screen directly clicks the menu operation mode, making parameter adjustment convenient and intuitive.

2. All the mechanisms, including the bottom cabinet, conveyor belt, stop rod, and fasteners, are made of stainless steel and aluminum profiles, never rust, pollution-free interference, in line with GMP environmental requirements.

3. The working status and failure of the equipment are reminded and warned, making the operation and maintenance more convenient and safe.

4. Set the total number of labels and remaining management functions. When the total number of labels reaches the set value and the remaining number of labels is equal to or less than the set value, the system will stop and alarm.

5. All system control components have international standardized certification and pass strict factory inspection and testing to ensure the reliability of various functions.

In the modern production line, the role of the bottle label machine cannot be underestimated. Choosing a bottle label machine with excellent performance and reliable quality will bring new opportunities for the production and development of enterprises.

If you are considering purchasing or installing a new labeling machine, please contact Pharmapack today for a free quote. Our team of experts is ready to provide you with the best and most appropriate solution for your specific needs. Contact us today to find out how we can improve your production line for maximum efficiency and profitability.