There are some problems in the operation of the traditional packing machine, such as unstable operation of the equipment, loud noise, easy failure, long time to replace the bottle, complex operation, etc. These problems not only affect the production efficiency, but also increase the operating cost of the enterprise.

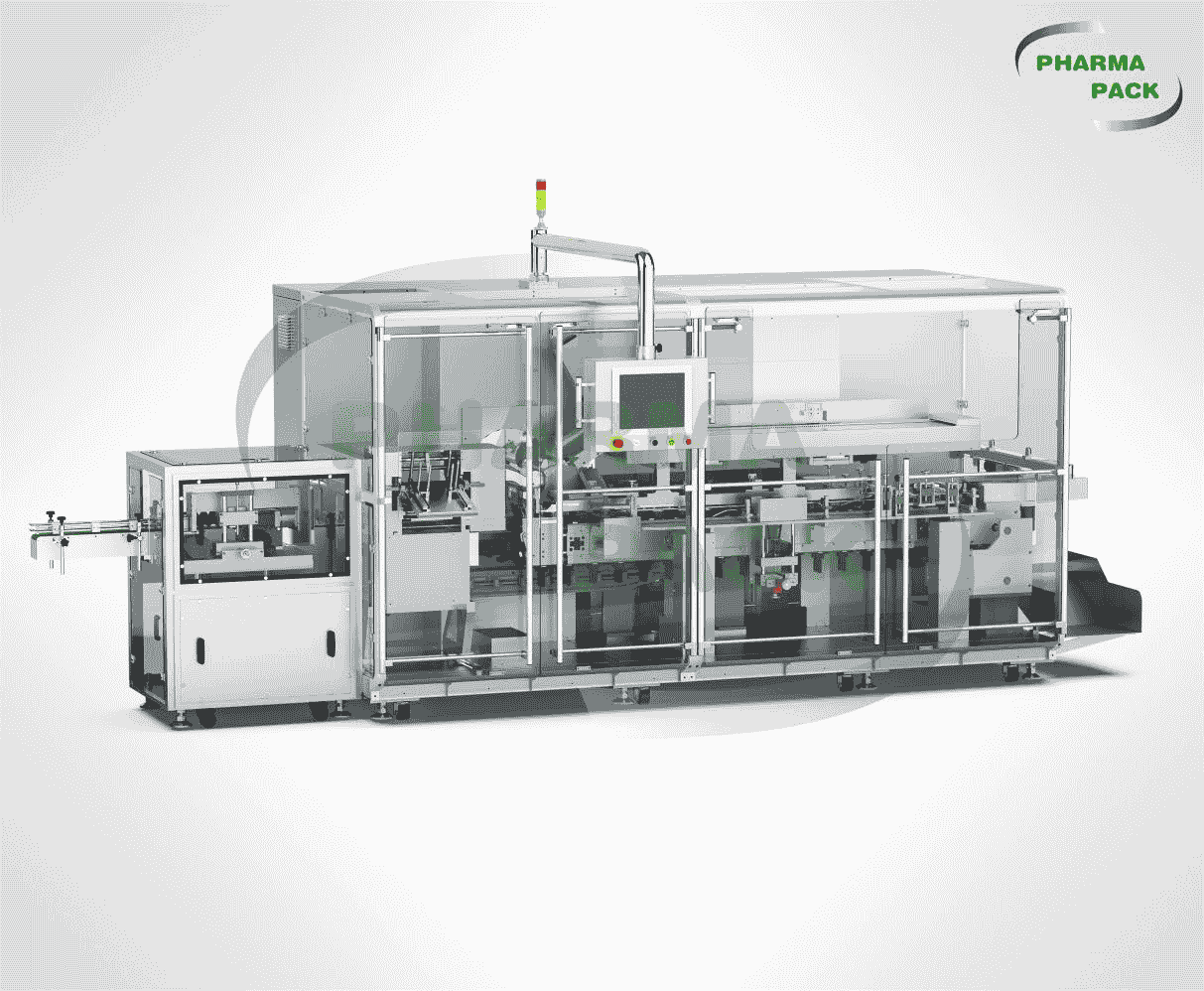

Pharmapack continuous packing machine ALFBC-40 has carried out technological innovation and improvement on these problems, and has brought a new solution to the packaging industry with its unique box structure design and advanced technology.

The function of the continuous packing machine is to put the bottle, blister board, material holder, strip bag and other materials into the paper box and seal the box; It can be used with the origami machine, and the instructions and products can be boxed together for food, medicine, cosmetics and other industries to realize the packaging of bottles, blister boards, material trays, and strip materials.

1. Unique box structure design: the drive and auxiliary drive parts are all installed in the box cabinet, effectively preventing paper scraps and material debris from falling into the drive mechanism, ensuring the safe operation, health, maintenance and maintenance of the equipment.

2. Low noise, smooth operation: the feed belt and the delivery belt use PU synchronous belt containing metal rope to transport materials and cartons, which reduces noise and improves operation stability.

3. Flexible adjustment: The suction box and pre-opening box parts are driven by independent servo motors, and the horizontal and vertical directions are adjusted flexibly to meet different production needs.

4. Efficient packing speed and stability: the packing part adopts the form of mechanical synchronous push rod, which completes the reciprocating packing action while moving synchronously with the feed conveyor belt to improve the packing speed and stability.

5. Unique sealing movement: The sealing part adopts a specific connecting rod curve (approximately elliptical) movement, and completes the reciprocating sealing action in the movement to improve the sealing quality.

6. Intelligent power system: bottle delivery, box delivery, box sealing, printing, box out and other parts are driven by servo motors, providing power for intelligent adjustment and bottle replacement, breaking through the traditional way of bottle replacement, greatly reducing the time of bottle replacement, reducing human labor intensity, making the equipment more intelligent and more modern.

7. Convenient adjustment and recording: All mechanisms that need to be adjusted due to the replacement of varieties are equipped with adjustment mechanisms with digital displays, which are easy to adjust records and eliminate misoperation.

8. Easy cleaning and maintenance: the feeding belt, the delivery belt, the box embryo part and all the sealing mechanism are installed by hanging, easy to clean and maintain.

9. Equipment safety protection: the main motor is equipped with overload protection to ensure no overload operation of the equipment and ensure equipment safety.

10. Convenient equipment debugging: manual and electrical point function is configured to facilitate equipment debugging.

11. Intelligent incoming material detection system: equipped with incoming material detection system, there is material in the box, under the instruction, no material is empty operation, reduce the number of equipment start-stop.

12. Easy to learn, easy to operate control system: programmable controller PLC control, Chinese interface touch screen, easy to operate.

13. Comprehensive automatic fault diagnosis and monitoring alarm system: with automatic fault diagnosis function and comprehensive, real-time monitoring alarm and display system, making operation and maintenance more convenient.

The introduction of Pharmapack continuous packing machine ALFBC-40 aims to solve a series of problems in the traditional packing process, which not only affect production efficiency, but also increase the operating costs of enterprises.

1. Low production efficiency: Traditional packing machines are often slow and complex to operate, resulting in low production efficiency. The ALFBC-40 significantly improves the overall efficiency of the production line through its efficient packing speed and stability.

2. Unstable operation of the equipment: many old packing machines will be unstable at high speed, resulting in product damage or unqualified packaging. The ALFBC-40's mechanically synchronized pushrod design and stable conveyor system ensure the stability of the equipment at high speeds.

3. Noise and vibration problems: the noise and vibration generated by the old box packing machine during operation often have a negative impact on the working environment. The ALFBC-40 uses a PU synchro-strap containing metal rope, which effectively reduces noise and vibration and provides a quieter working environment.

4. Long time to change the bottle type: the traditional box filling machine needs a lot of time to adjust when changing different bottle types, the intelligent power system and digital display adjustment mechanism of ALFBC-40 greatly reduce the time required to change the bottle type, improving the flexibility of production.

5. Complex operation and high misoperation rate: Complex operation process increases the training cost of operators and the possibility of misoperation. The ALFBC-40's easy to learn, easy to operate control system, as well as equipped with automatic fault diagnosis and monitoring alarm system, simplifies the operation process and reduces the error rate.

6. Cleaning and maintenance difficulties: Traditional box packing machine cleaning and maintenance often require a lot of time and manpower. The ALFBC-40's suspension mounting and easy cleaning design make daily maintenance easier and faster.

7. Poor equipment safety: Safety issues have always been the focus of the manufacturing industry, ALFBC-40 through the overload protection of the main motor and a comprehensive automatic fault diagnosis system to ensure the safety of equipment operation.

Pharmapack continuous packing machine ALFBC-40 with its unique advantages and characteristics can solve the problems existing in the operation of most traditional packing machines, improve production efficiency and reduce the operating costs of enterprises.

Machines are a big investment, so you need to make sure you buy the right machine to avoid any incompatibility issues in the long run.

Choose a continuous packing machine manufacturer that provides consulting services throughout the entire process of machine customization. This guarantees that you will get a machine that is perfectly suited to the specific needs of your business. If you need help with packaging solutions, please feel free to contact us, one of the leading packaging machine manufacturers in China. Pharmapack is happy to help you.