In the pharmaceutical industry, compliance and efficiency of pharmaceutical packaging are of Paramount importance. The traditional manual labeling method is not only inefficient, but also prone to human error, which affects product quality and compliance. To solve this problem, the PharmapackLFOS-20 booklet outserter was created.

The LFOS-20 booklet outserter is an automated packaging device specifically designed for the pharmaceutical industry that will automatically attach instructions to the top of the bottle for full automation. The equipment adopts advanced control system and precision mechanical structure to ensure accurate and efficient instruction manual paste to meet the high requirements of the pharmaceutical industry for packaging quality.

Here's how the LFOS-20 booklet outserter works:

1. Manual input: Put the pre-folded manual into the manual bin, and the conveyor belt will automatically transport the manual to the suction mechanism.

2. Manual adsorption: Rotate the suction cup on the suction arm to automatically absorb the manual and place it above the bottle cap.

3. Positioning glue: When the bottle reaches the designated position, the electric eye sends a signal, and the PLC controls the hot spot glue machine to accurately dispense glue on the bottle cap.

4. Manual pasting: Press the manual on the bottle cap with a vacuum suction cup to complete the pasting.

5. Detection and elimination: electric eye detection of unaffixed instructions or pasted unqualified bottles, automatically removed to the collection box to ensure product quality.

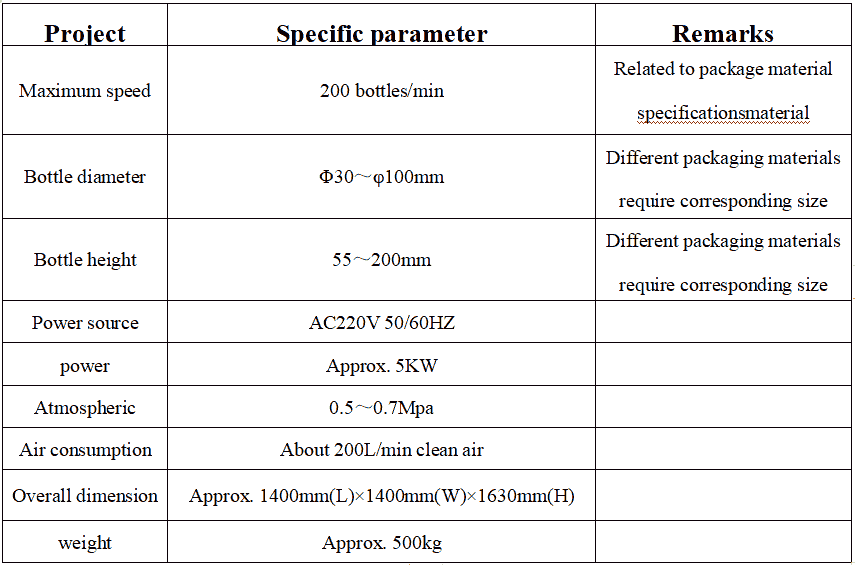

1. High-speed operation: The maximum speed of the LFOS-20 booklet outserter can reach 200 bottles/min, greatly improving production efficiency and meeting the needs of large-scale production.

2. Accurate positioning: The equipment is equipped with a high-precision electric eye detection system, which can accurately locate the position of the bottle and the instruction manual to ensure that the instruction manual is accurately pasted without omission or deviation.

3. Strong adaptability: suitable for a variety of specifications of bottles and instructions, can easily adjust the size of parts, to meet the production needs of different products.

4. Easy operation: using microcomputer control system and touch screen operation interface, parameter adjustment is convenient and quick, operators can quickly get started.

5. Reliable quality: All system control components have international standardized certification to ensure stable and reliable equipment operation and long service life.

6. Safety and environmental protection: stainless steel and aluminum profile manufacturing, pollution-free, in line with GMP environmental requirements, to ensure the safety and health of the production environment.

With its high speed, accuracy and reliability, the PharmapackLFOS-20 booklet outserter has become the preferred solution for automated packaging in the pharmaceutical industry. It can help enterprises improve production efficiency, reduce labor costs, improve product quality, ensure compliance, and provide strong support for the rapid development of the pharmaceutical industry.

If you are looking for an efficient, accurate and reliable automated packaging device, the Pharmapack LFOS-20 booklet outserter is the perfect choice for you!