In daily life, have you ever wondered how these products are produced and how their quality is guaranteed? This leads us to the topic at hand: tracking and tracing systems for bottling lines.

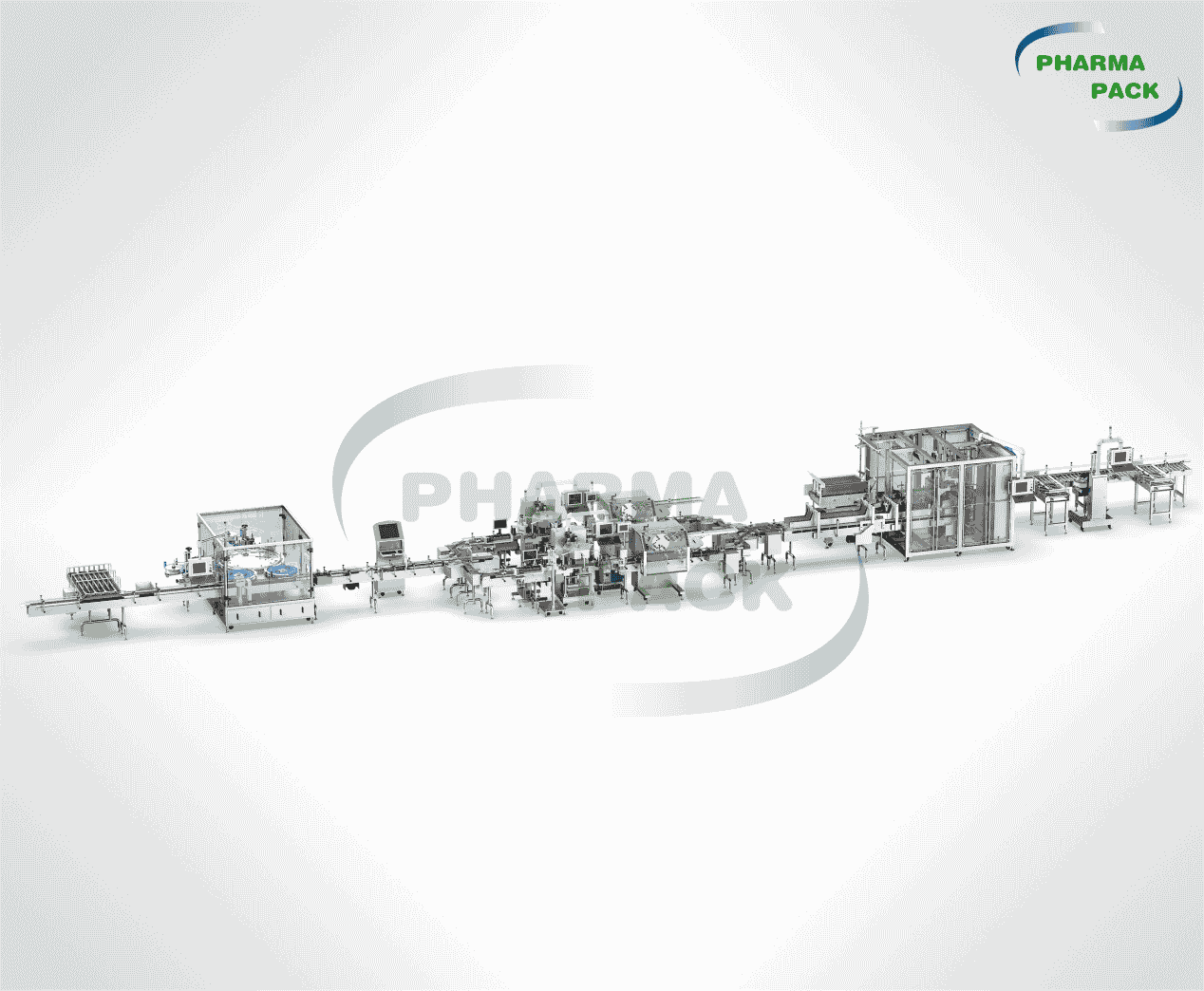

For bottled products such as medicines and food, the quality control of the production process is particularly important. The Pharmapack bottling traceability system, as an industry-leading solution, integrates advanced equipment such as a loading buffer disk, vertical round bottle labeling machine, 360° panoramic camera inspection machine, and box packing machine to efficiently complete key production processes such as bottle bottom labeling, inspection and verification, box packing, and so on.

1. Multi-functional integration: After the system obtains the code text, it can print, inkjet, automatic labeling, weighing, and testing to meet the diversified production needs of enterprises.

2. Accurate detection and rejection: Utilizes an integrated camera system to ensure the quality of each product by detecting and rejecting defects.

3. Comprehensive information traceability: Manages information of products and their packaging units (bottles, boxes, cartons, etc.) to achieve traceability throughout the product lifecycle.

4. Unique identification code tracking: Each product is assigned a unique "one thing one code" identity code to achieve product tracking and management throughout the process.

5. Compliance with international standards: The system fulfills the requirements of the National Drug Electronic Regulatory Network and adheres to the US FDA 21 CFR Part 11 standards for electronic records and electronic signatures.

6. Data link traceability: Records and saves drug traceability information in a timely and accurate manner, forming an interconnected drug data chain, and realizing that the source and destination of the whole process of product circulation can be traced.

7. Quality assurance and anti-counterfeiting: Effectively prevents counterfeit drugs, ensures that drugs enter legal channels, and guarantees drug quality.

The Pharmapack bottling traceability system has a wide range of applications, suitable not only for pharmaceutical, health care products, food, confectionery, daily chemical, and electronic products industries but can also be customized to meet the special requirements of different industries.

For example, in the pharmaceutical industry, the Pharmapack bottling traceability system can realize the full traceability of the drug production process to ensure the quality and safety of drugs. In the food industry, the system can track food production, processing, packaging, and other links to ensure food safety. In the electronic product industry, the system can track the production, testing, packaging, and other processes of the product to improve product quality.

The Pharmapack bottling traceability system is a multi-functional, high-precision, and high-efficiency bottling production line traceability system, which can help enterprises achieve comprehensive control of product quality, improve production efficiency, reduce production costs, and enhance market competitiveness.

With advancements in technology, the Pharmapack bottling traceability system will be a key tool in enhancing the competitiveness of bottling production lines and promoting the development of the bottling industry towards intelligence, networking, and data.

Contact our sales service hotline at 400-998-5907 or visit us at 16 Huangqishan Road, Yonghe Economic Development Zone, Guangzhou Economic and Technology Development Zone. For more details, click 'Contact us' on our website.