In the packaging industry, particularly in sensitive areas such as pharmaceuticals and food, product quality and safety are of paramount concern to consumers. The industry faces challenges such as low production efficiency, asymmetric information, and the difficulty of guaranteeing product quality.

With the increasing market demand for transparency and traceability, the Pharmapack carton packaging line traceability system has emerged. The introduction of the carton line traceability system not only enhances production efficiency but also ensures product quality and safety throughout its lifecycle, meeting industry standards and the high expectations of consumers.

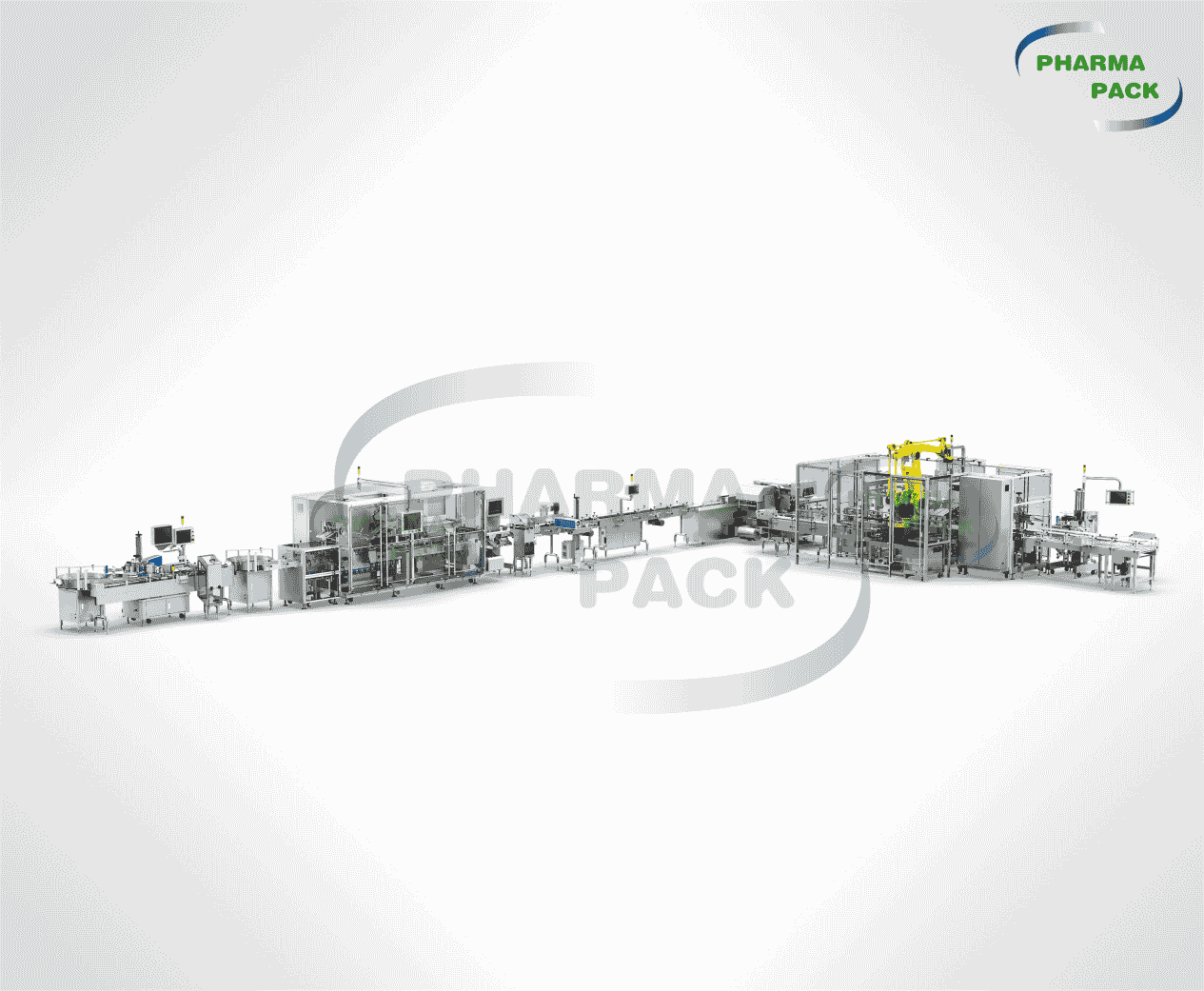

The Pharmapack carton traceability system is composed of equipment such as a continuous cartoning machine, box labeling and weighing sequencer, and a semi-automatic cartoner. These devices efficiently complete production processes such as cartoning, labeling, weight checking, product serialization, boxing, and box serialization.

The system is designed to be compact, aesthetically pleasing, and easy to maintain. It is particularly suitable for factories with limited space and can be custom-designed to meet various client needs. It is widely used in industries such as pharmaceuticals, health products, food, confectionery, daily chemicals, and electronic products.

1. After obtaining the code, it carries out printing, coding, automatic labeling, and weight checking to meet the diverse needs of enterprises. This series of operations not only improves production efficiency but also ensures the accuracy and traceability of product information.

2. An integrated camera inspection rejection system effectively eliminates defective products in real-time, ensuring that the products entering the market meet high-quality standards. This significantly reduces the rate of defective products and enhances the company's brand image.

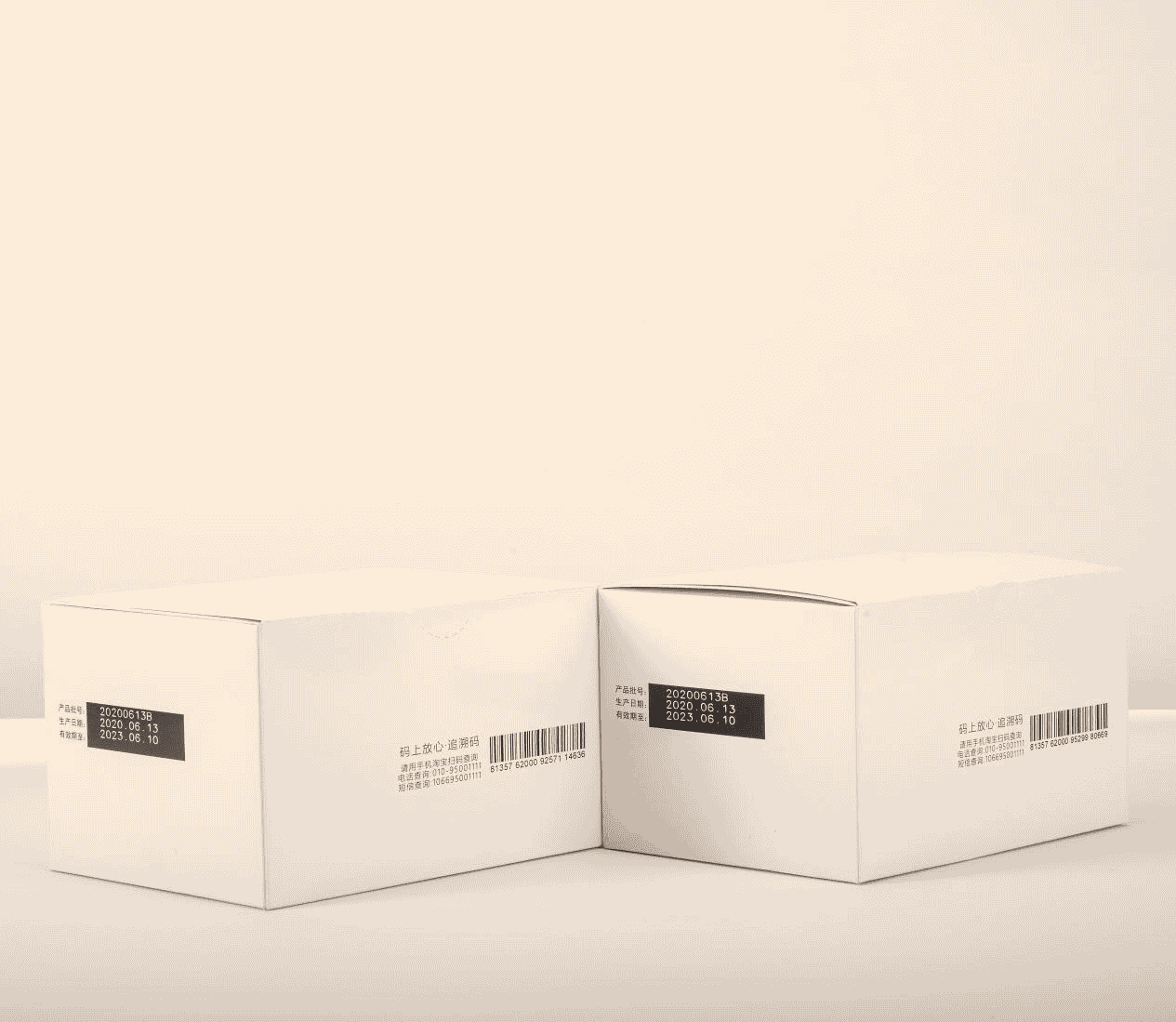

3. It achieves informationized product traceability for product and packaging units (bottles, boxes, cartons, bundles, pallets, etc.), allowing enterprises to easily grasp information about product production, circulation, and sales, improving management levels.

4. Each product is assigned a unique identity code of "one item, one code, track item and code simultaneously," providing comprehensive tracking of the product. This allows enterprises to better understand product dynamics and offers strong support for marketing and after-sales services.

5. It records and saves pharmaceutical traceability information in a timely and accurate manner, forming an interconnected pharmaceutical data chain. This achieves full-process traceability of product circulation, providing consumers with a safety guarantee.

6. It effectively prevents counterfeit and substandard drugs, ensuring that drugs enter legitimate channels and maintaining drug quality. This protects the rights of consumers and creates a healthy market competition environment, which is conducive to the sustainable development of enterprises.

In summary, the Pharmapack carton packaging line traceability system, with its outstanding performance and broad application prospects, has become an important promoter of the packaging industry's move towards intelligence and informatization. By deploying this system, enterprises can effectively enhance production efficiency and product quality, as well as better respond to market changes, injecting strong momentum into the development of the enterprise.

Pharmapack's tracking and tracing system for carton packaging lines, with its efficiency, precision, and ease of maintenance, provides strong support for various industries. While improving production efficiency, it ensures product quality and safety, serving as a powerful guarantee for enterprises to achieve sustainable development.