At a time when food safety and product quality have become the focus of consumers, food production companies urgently need an efficient and accurate quality traceability system to ensure the full traceability of products. As an intelligent solution for quality traceability, the Pharmapack bottling line traceability system has become a leader in the industry with its advanced technology and flexible configuration.

The bottling line traceability system is a comprehensive management system that integrates modern information technology, automatic identification technology and data analysis capabilities. It aims at the production process of bottled products and gives each product a unique identity (such as QR code, RFID tag, etc.), realizing accurate recording and real-time monitoring of the entire process from raw material procurement, production and processing, quality inspection to finished product packaging, logistics transportation, and market sales.

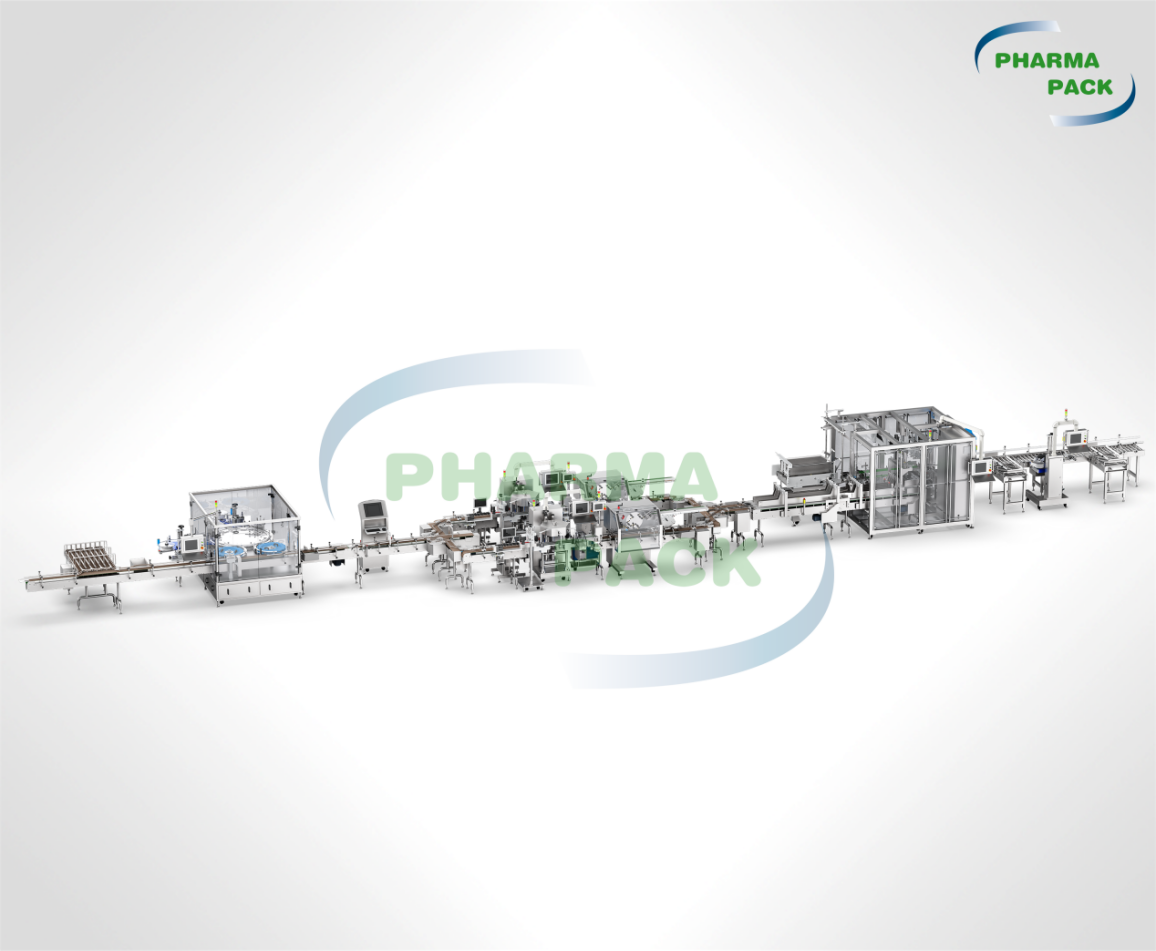

The Pharmapack bottling line traceability system consists of a series of high-efficiency and high-precision equipment, including a loading buffer tray, a vertical round bottle labeling machine, a 360° panoramic camera inspection machine, and a box making and packing all-in-one machine. These devices work together to quickly and effectively complete key production processes such as bottle bottom coding and labeling, inspection and verification, and box making and packing.

1. High-speed and efficient labeling detection

The system uses a vertical round bottle labeling machine, which can accurately attach the label to the bottom of the bottle while the bottle rotates at high speed, ensuring the beauty and firmness of the label. At the same time, the application of the 360° panoramic camera inspection machine can perform all-round inspection and verification of the bottle body without affecting the production speed.

2. High-precision cameras with international top technology

The Pharmapack bottling line traceability system is equipped with high-precision cameras with international top technology, which can capture tiny defects and ensure that the product quality meets the highest standards.

3. Servo control system

The whole machine adopts a servo control system, which not only improves the detection speed, but also improves the stability and reliability of the system. This enables the Pharmapack bottling line traceability system to maintain extremely high accuracy while running at high speed.

The Pharmapack bottling line traceability system has been widely used in many industries due to its excellent performance and wide range of application scenarios. In the pharmaceutical and health care products industry, the system ensures the safety and effectiveness of products; in the food and confectionery industry, the system improves product transparency and consumer trust; in the daily chemical and electronic products industry, the system helps companies achieve standardization and normalization of production processes.

The Pharmapack bottling line traceability system is not only a tool to improve production efficiency, but also an important part of corporate quality management. Through an intelligent and precise traceability system, companies can better meet consumers' expectations for safety and quality, while also laying a solid foundation for the long-term development of the brand. In this era of increasingly stringent quality and safety requirements, choosing the Pharmapack bottling line traceability system is undoubtedly an important step for companies to move towards the future.