In modern industrial production, labeler is an important part of automated packaging equipment, and its selection is directly related to production efficiency, product quality and cost control. Faced with a wide range of labeler models and brands on the market, how to choose the labeler that best suits your production line has become the focus of many companies.

1. Product type and labeling position

First of all, clarifying the type of product you need to label and the labeling position is the key to choosing a labeler. Products come in a variety of forms, including flat, flat bottles, round bottles, etc., and the labeling positions are also different, such as flat pasting, single-sided or cylindrical pasting, multi-sided pasting, partial or full coverage of cylindrical pasting, and concave and corner pasting. These factors directly determine the type and function of the required labeler.

2. Degree of production automation

Choose a manual, semi-automatic or fully automatic labeler according to the degree of automation of the production line. The higher the degree of automation, the lower the labor cost, but the initial investment is also relatively high. Enterprises should weigh the pros and cons and make choices based on their actual situation and future development plans.

3. Perfection of supporting equipment

Perfect supporting equipment can expand the functions of the host and improve overall production efficiency. For example, some high-end labelers can be used in conjunction with hot stamping ribbon printers to print label content while labeling, achieving multiple uses of one machine. In addition, the compatibility of the equipment should also be considered so that the production line can be easily upgraded or expanded in the future.

4. Manufacturer's after-sales service capabilities

After-sales service is an important factor that cannot be ignored when purchasing a labeler. Good after-sales service can ensure that the equipment is promptly and effectively resolved when problems arise, reducing losses caused by downtime. Therefore, when choosing a labeler, the manufacturer's after-sales service system, response time, maintenance capabilities, and customer reputation should be focused on.

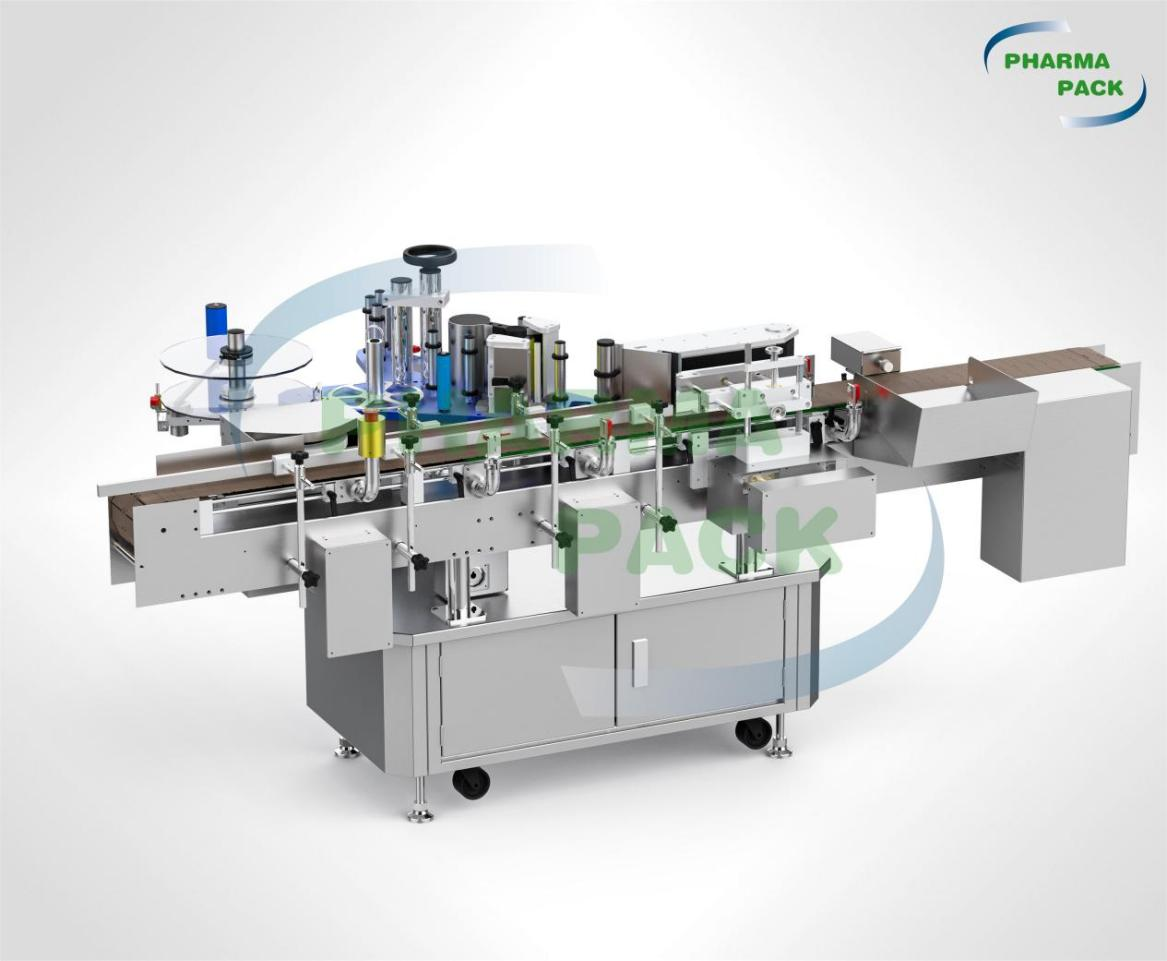

As a well-known brand in the labeler field, Pharmapack provides a variety of labeler models to meet the needs of different companies. The following are some recommended models:

1. Flat labelerPLB-4120: Suitable for labeling the top and bottom surfaces of round bottles, bottle caps, boxes or bags, suitable for industries such as medicines and health products, and can be used with a hot ribbon printer to achieve synchronous labeling and printing.

2. Vertical round bottle labelerPLB-1120: Suitable for labeling cylindrical surfaces such as vials, ampoules, oral liquid bottles, suitable for the pharmaceutical industry, and can also be used with a printer to achieve fast automatic labeling and product identification.

3. Horizontal labelerPLB-2150: Designed for high-speed labeling of small round bottles, with high labeling accuracy, suitable for the pharmaceutical industry, and can also be used with a printer.

4. Rotary labelerPLBR-124032: Suitable for industries such as food, medicine, and cosmetics, it can automatically label during the process of star wheel conveying bottles to achieve efficient product identification.

5. L-type labeler PLB-1160R: suitable for labeling cylindrical surfaces such as vials, ampoules, and oral liquid bottles, suitable for the pharmaceutical industry, and can be matched with a printer to achieve fast and automatic labeling.

The diverse labeler models provided by Pharmapack can meet the labeling needs of different industries and products, helping you improve production efficiency and product quality.

When choosing a labeler, you should not only consider current production needs, but also possible future expansion and upgrades. With its high quality, high efficiency and perfect after-sales service, Pharmapack labeler is your ideal choice to improve production line efficiency and product quality. Investing in a suitable labeler will bring long-term economic benefits and market competitive advantages to your company.