Today, when intelligence and automation are increasingly becoming the mainstream of industrial development, cartoning machines occupy a pivotal position in the intelligent packaging industry. It can not only significantly improve packaging efficiency and reduce labor costs, but also ensure the accuracy and consistency of product packaging, bringing revolutionary changes to the food, pharmaceutical, daily chemical and other industries.

The efficiency of the intelligent cartoning machine is mainly reflected in its high-speed and continuous operation capabilities. Through advanced control systems and precise mechanical structures, intelligent cartoning machines can realize a series of operations such as automatic product loading, precise positioning, rapid cartoning, and automatic carton sealing. The entire process is smooth and efficient.

In terms of accuracy, the smart cartoning machine also performs well. By integrating advanced sensors and visual recognition systems, smart cartoning machines can detect the location, quantity, quality and other information of products in real time to ensure that the products in each box meet preset requirements. This accuracy not only improves the packaging quality of products, but also wins the trust and praise of consumers for the company.

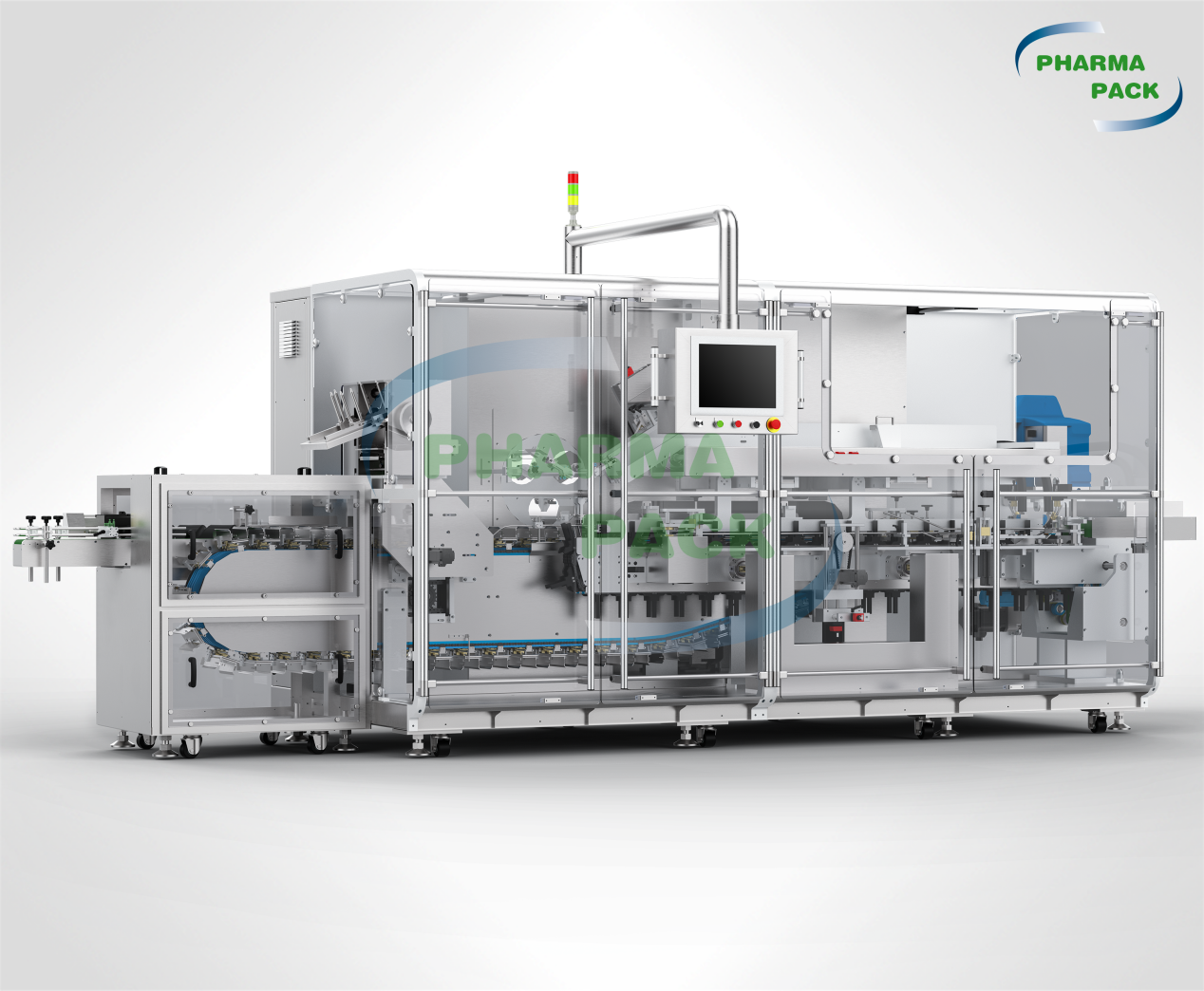

Among the many cartoning machines, Pharmapack focuses on the R&D and manufacturing of intelligent packaging equipment and provides a variety of fully automatic high-speed cartoning machines. The maximum speed of its full-servo continuous cartoning machine can reach 400 boxes/minute, while the speed of the intermittent cartoning machine can also reach 120 boxes/minute. These equipment are well designed and can adapt to the needs of production lines of different sizes, further promoting the intelligentization process of the packaging industry.

1. Continuous cartoning machine ALFBC-25

Pharmapack's continuous cartoning machine ALFBC-25, with its full servo design, demonstrates the characteristics of high productivity, high precision and easy operation and maintenance. This machine abandons the traditional complex mechanical structure, realizes the suction and opening of boxes in one go, and has the integrated function of delivering bottles and instructions. In addition, its hull width can be adjusted accordingly to the diameter of the bottle, greatly increasing the machine's flexibility.

2. Intermittent cartoning machine LFBI-1012

The maximum speed can reach 120 boxes/minute. The equipment has strong adaptability and can be used with the origami machine to realize the packaging of bottles, blister boards, material trays, strips and packaging materials and instructions together. It is more suitable for smaller-scale production needs. , which can achieve a good balance between accuracy and efficiency.

Cartoning machines have broad application prospects in food, pharmaceutical and daily chemical industries. In the food industry, it helps pack products into packaging boxes quickly and efficiently, ensuring product freshness and hygiene. In the pharmaceutical industry, cartoning machines ensure accurate packaging of medicines, prevent mis-packaging and missing packaging, and improve the safety of medicines. In the daily chemical industry, cartoning machines help companies realize automated production, reduce labor costs, and improve overall efficiency.

As an important piece of equipment in the intelligent packaging industry, cartoning machines are promoting the transformation of production models in various industries due to their high efficiency, accuracy and automation. With the continuous advancement of technology, cartoning machines will continue to play a greater role in the packaging field, bringing higher production efficiency and better product quality to enterprises. Choosing a suitable cartoning machine will inject new impetus into the future development of the enterprise.