A tablet counter refers to a machine for counting medicines such as capsules, tablets, and granules. The machine is generally small in size, accurate in counting, and easy to operate. The contact surface of the counter is made of stainless steel and is an ideal equipment for counting bottled, bagged, and canned products in various related industries.

The counting machine industry has become a key to pharmaceutical packaging and greatly improved international competitiveness. As the leader of the national standard for automatic counting and packaging lines, Pharmapack is leading the new development direction of the entire industry. This article introduces the working process and application characteristics of Pharmapack’s modular counters and analyzes the advantages of the machine.

Modular counter applications

A modular counter is a machine suitable for pharmaceuticals packaging. At the same time, the equipment can handle various complex industrial components from electronics, aerospace, medical, hardware, injection molding, and more. Furthermore, the modular counter can quickly and accurately assemble the correct number of tablets in vials. The versatility of modular counters has made them highly desired by many industry professionals.

The working process of Pharmapack’s modular counters

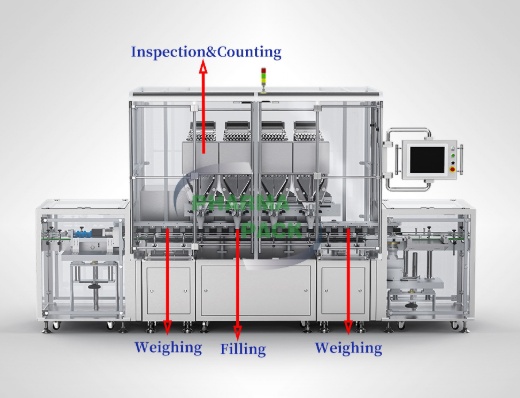

Pharmapack has a complete range of modular counters. The counters are equipped with a servo-control system, ensuring that the tablets can enter the medicine more quickly and accurately. The working process of the modular counter is simple.

First, the tablets can be loaded into the hopper manually or automatically, and then the tablets will be sent to the three-grade vibrating plates. By adjusting the vibration frequency, the tablets can be continuously and neatly passed through the channel of the vibrating plate and slide down to the nozzle gate. The modular counter is also equipped with optical inspection cameras and an infrared dynamic scanning sensor to control the number of tablets. When the required amount of tablets is reached, the tablets will fall into the medicine bottle through the filling nozzle. Finally, the medicine bottle is moved by the screw to the next station.

Pharmapack installation is equipped with an incoming sensor on the modular counter. The device can detect whether there is a missing medicine bottle in the screw, and can also control the material not to be unloaded when there is no medicine bottle, avoiding unnecessary waste and environmental pollution caused by material scattering.

The advantages of using Pharmapack’s modular counters

1. Servo-control system: The product is equipped with a servo system, which can control the main and secondary nozzle gates. The system has the characteristics of high precision and can work for long hours. Moreover, the system’s design is separate from the nozzle gate, which is convenient to remove and clean.

2. Modular design: Each unit can be designed according to the modular concept. Each module can be replaced, added, or subtracted individually, and multiple modules can also be combined as needed. Each module can be pulled out and maintained separately, which is more convenient and faster.

3. Revolving nozzle gate: The nozzle gate can easily handle small tablets with a diameter of 2-3mm, avoiding the problem of small tablets leaking. At the same time, the nozzle gate controlled by the servo system can reduce noise to the greatest extent.

4. Higher demand for larger size tablets: The maximum size range of the tablets is increased from the traditional Φ13mm to Φ20mm, which can better meet the bottling needs of different tablet sizes in the market.

Product Recommendation: Pharmapack’s modular counters selection

Under the background of the rapid development of the pharmaceutical industry, the counting machine has technical significance, and it is in great demand. Pharmapack is an expert in the counting and packaging line. The equipment on the modular counter production line is manufactured according to international standards and meets the requirements of GMP, FDA, and other certifications. The following is an introduction to some modular counters of Pharmapack:

LFM-24 Modular Counter is suitable for Φ3mm-Φ13mm tablets, capsules, and other solid granules, with a bottling speed reaching 18,000 pieces of tablets per minute.

On the other hand, LFM-08 Modular Counter is designed for Φ3mm-Φ20mm tablets. The highest bottling speed of this machine is 6000 pieces of tablets per minute.

LFM-32 Modular Counter is an automatic counting device, due to its small size, this machine can be integrated into any packaging line for Φ3mm-Φ20mm tablets, and the maximum production speed can reach 24,000 pieces of tablets per minute.

Finally, the ALFM-32C In-motion Modular Counter is the latest AI technology tablet counting and sieving machine that allows for a 100% special visual inspection of tablets, capsules, and soft gels, and the maximum production speed can reach 24,000 pieces per minute.

Contact us if you are interested in implementing modular counters.