In the rapidly advancing field of pharmaceuticals, staying at the technological forefront is of utmost importance. Pharmapack, a major manufacturer of pharmaceutical packaging equipment, is known for its innovative technology and exceptional quality. They have created a number of new machines designed to redefine quality control in the pharmaceutical industry through the use of enhanced automation and artificial intelligence. In this article, we will explore Pharmapack's upcoming product and understand how these machines enhance the safety, accuracy, efficiency, and versatility of pharmaceutical packaging.

Modular Counter with Laser Detection LFM-08

Precise medication counting is imperative for patient safety. Pharmapack's Modular Counter with Laser Detection LFM-08 employs advanced laser detection technology to improve the anti-interference performance of the counting process, effectively eliminating detection blind spots.

This single module laser modular counter can eliminate detection blind spots by using directional single-sided emitted light instead of traditional infrared light with a large scattering angle. This prevents inaccuracies in counting and ensures the contents match the label declaration. It enhances the precision, transparency, and reliability of the pharmaceutical packaging process. The device is widely used in counting canisters for solid formulations such as pills, tablets, soft and hard capsules, and other solid preparations in the pharmaceutical, food, pesticide, and chemical industries.

Twin-Stick Packing Machine ALFVS-01D

Strip packaging provides versatile and efficient packaging for powdered medications. Pharmapack's Twin-Stick Packing Machine ALFVS-01D is equipped with an innovative secondary longitudinal sealing mechanism that allows the strip package to be divided into two duplex strips after longitudinal sealing and molding.

This dual-channel operation not only increases the diversity of the packaging but also speeds up the packaging process, adding to enhanced efficiency. To fulfill a variety of product requirements, the servo-driven rotary cutting machine can instantly switch between different packing lengths and widths. These features collectively provide outstanding versatility and throughput for strip packaging production, making it suited for metered packing of grains, powders, tablets, and liquids.

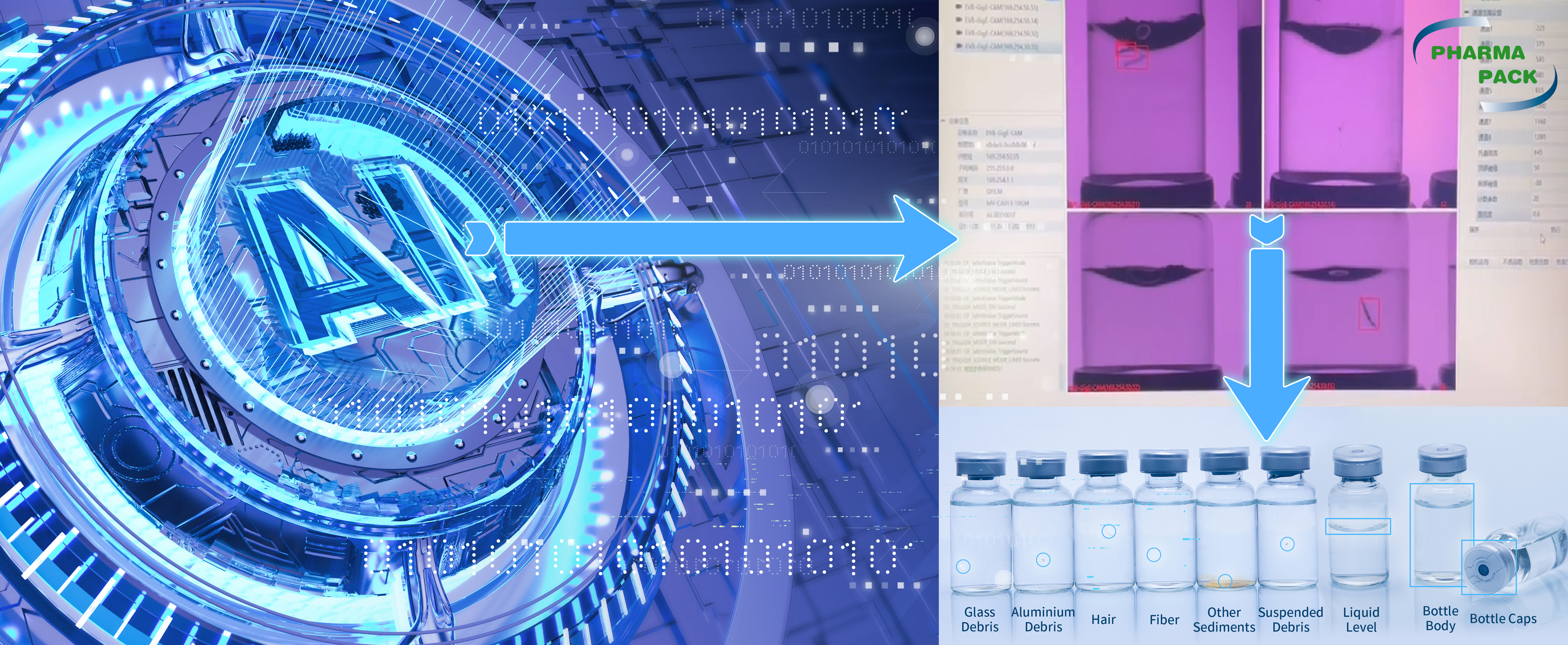

AI Continuous Inspection Machine LFIM-48

Continuous inspection is vital for assuring the quality of large-scale pharmaceutical packaging. The AI Continuous Inspection Machine LFIM-48 from Pharmapack combines multi-point AI vision detection with a rejection device to provide consistent and uninterrupted inspection.

The LFIM-48 is equipped with an AI visual inspection system, integrating a high-definition industrial camera with 1.2 million pixels, a high-performance server, strobe control technology, and LED lighting. This system enables more stable, faster, and reliable quality inspection. The system utilizes a self-developed AI deep learning algorithm, which enables rapid identification of internal foreign objects, fibers, impurities, and external defects such as dirt and scratches through image preprocessing, labeling training, and other methods.

During high-speed production processes, it can perform real-time, high-precision detection and sorting. Once non-compliant products are detected, the PLC control system automatically rejects them, ensuring the removal of substandard items. Compared to traditional manual inspection methods, the AI visual inspection system significantly improves detection speed and accuracy. It automates rejecting non-compliant products, preventing their mix-up with high-quality products. This meets the growing demand for meticulous quality inspection in pharmaceutical production. The entire system achieves both intelligent and automated detection and sorting while ensuring that the final product meets high-quality standards.

AI Continuous Inspection Machine with Leakage Detection ALFIM-72

Ensuring proper fill levels, seam integrity, and component is crucial for quality control in pharmaceutical packaging. The AI Light Continuous Inspection Machine with Leakage Detection ALFIM-72 from Pharmapack combines advanced artificial intelligence visual detection with high-voltage leak detection, reliably identifying defects and preventing further processing of defective products. This equipment is widely applicable for the automatic inspection of liquid formulations such as vials, ampoules, eye drops, injectables, oral liquid bottles, and more.

The AI inspection system performs complex image analysis to accurately detect defects in liquid levels, bottle bodies, bottle caps, impurities, and suspended matter inside the product. Additionally, ALFIM-72 is equipped with a high-voltage discharge leak detection device for more precise leakage detection. By placing the ampoule to be tested between the two electrodes of the device and then applying a high-voltage pulse current to the ampoule, any tiny cracks or holes in the ampoule's body will result in a leakage current. This allows for determining whether the product has a defect in terms of leakage.

This device is highly sensitive and can detect leaks as small as 1 micron or even smaller. This effectively prevents ampoules with tiny cracks from entering the market.

Pharmapack's upcoming product utilize automation, artificial intelligence, and laser technologies to provide solutions that enhance quality control and adapt to the industry's ever-changing needs. LFIM-48, ALFIM-72, LFM-08, and ALFVS-01D offer new opportunities for the safety, precision, efficiency, and flexibility of the packaging processes for pharmaceutical manufacturers. Pharmapack's commitment to innovation not only redefines pharmaceutical quality control but also shapes the future of the industry. Explore Pharmapack's official website now to see the future of pharmaceutical quality control!