The evolution of packaging lines has been marked by significant advancements in technology, with modern systems now playing a pivotal role in enhancing efficiency, accuracy, and product quality. The shift towards automation and precision, driven by growing consumer expectations for high-quality and convenient packaging, has made servo-controlled technologies a vital component in contemporary production processes. As businesses seek to meet these rising demands, upgrading to state-of-the-art equipment is crucial for maintaining a competitive edge.

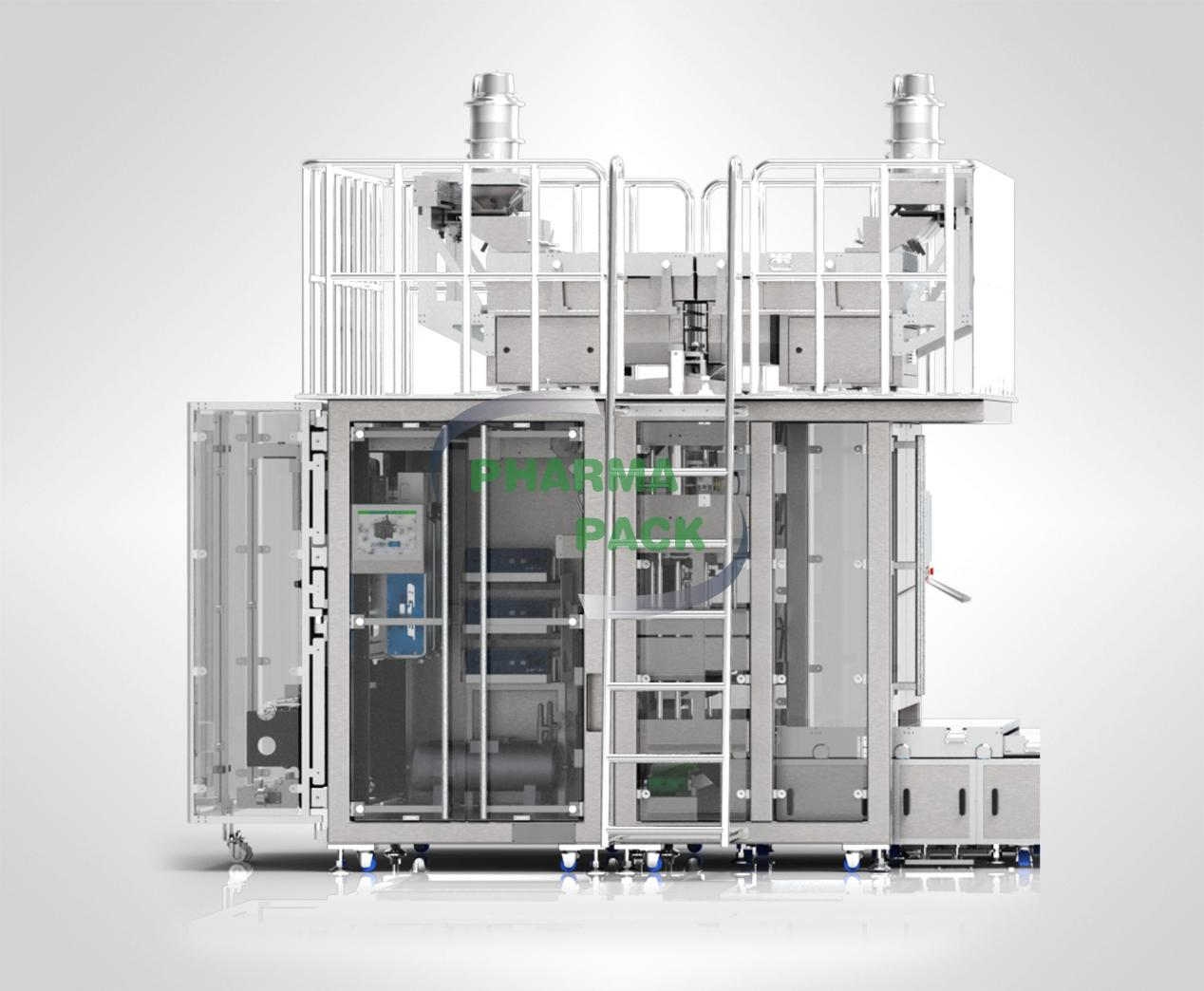

At Pharmapack, we are dedicated to delivering innovative packaging solutions that not only meet industry standards but also set new benchmarks for performance. Our servo-controlled stick packing machines, such as the ALFVS-12S, are designed with cutting-edge technologies to optimize packaging operations and deliver superior results.

Servo-controlled technology represents a significant improvement over traditional mechanical or pneumatic systems. Unlike older models that rely on mechanical cams or air pressure to operate, servo-controlled machines use precise electronic feedback loops to adjust speed, position, and torque dynamically. This enables a higher level of control over the entire packaging process, resulting in more accurate and consistent results.

Key benefits of servo-controlled technology include:

Improved Precision and Accuracy: Servo-driven systems can make fine adjustments in real time, ensuring that each package is consistent in weight, size, and seal quality.

Reduced Noise Levels: Unlike pneumatic systems that can be loud and disruptive, servo motors operate quietly, contributing to a safer and more comfortable working environment.

Energy Efficiency: Servo motors only consume energy when needed, making them more efficient than continuously running mechanical systems.

At Pharmapack, we integrate these advanced servo technologies into our packaging machines, including the ALFVS-12S, to deliver unmatched operational excellence. Our solutions enable businesses to meet ever-evolving industry demands while maintaining high standards of quality and efficiency.

When upgrading your packaging line, it's important to consider key features that ensure the machine will meet your production requirements. Below are some essential aspects to look for in a servo-controlled stick packing machine, with a focus on the ALFVS-12S from Pharmapack.

lHigh Production Speed and Adaptability: The ALFVS-12S offers a high production speed of up to 70 cuts per minute, featuring a 12-row configuration that allows for efficient processing of various product types, including tea, coffee, vitamins, and other powdered or granulated products. This adaptability is crucial for businesses that package multiple product lines, as it reduces the need for multiple machines and streamlines production.

lPrecision and Accuracy: Our ALFVS-12S machine incorporates high-precision I-Mark remote control and servo drive technology to achieve accurate filling and sealing. The servo-driven systems minimize noise and ensure each package meets exact specifications, reducing waste and ensuring consistent product quality.

lFilm Handling: The machine's EtherCAT bus servo encoder-controlled film tension ensures stable reeling, with automatic adjustment of the reeling speed to accommodate different film thicknesses and characteristics. By keeping film rolls within the chassis, contamination from dust is prevented, further enhancing the quality of sealing.

lSealing and Cutting: The ALFVS-12S features servo-driven vertical and horizontal sealing systems, which allow for adjustable torque settings that maintain a stable and quiet sealing process. The modular, multi-segment horizontal sealing rollers provide flexibility in seal length, while the servo-driven round cutting system ensures precise and consistent cuts for a professional finish.

lMeasuring and Filling: A variety of filling mechanisms are available to suit different product types, including measuring cup, screw, electronic counting, and liquid pump filling systems. The use of 316L stainless steel in the metering box helps prevent powder leakage and ensures the accurate dispensing of contents, which is essential for maintaining quality control.

lSafety and Convenience: To simplify operation and improve safety, the ALFVS-12S is equipped with a user-friendly touch screen interface that allows operators to easily adjust parameters. Integrated safety devices and automatic alarms for film changes add layers of protection, reflecting Pharmapack's commitment to creating efficient and safe machines.

Pharmapack’s ALFVS-12S goes beyond basic functionalities to incorporate advanced features that significantly enhance performance. These innovations include:

lDust Recovery System: An efficient dust recovery system using vacuum technology helps to recycle dusty materials and improve the tightness of stick packaging. This feature is particularly beneficial for products prone to generating dust during the filling process, as it minimizes product loss and keeps the workspace cleaner.

lVibratory Feeding System: The vibratory feeding system utilizes high-frequency vibratory cylinders to increase feeding speed and prevent material jams. This feature ensures a smooth and continuous flow of product into the packaging line, minimizing downtime and improving overall efficiency.

lOptional Components for Versatility: To cater to specific production requirements, Pharmapack offers optional components such as laser coding systems for date stamping and visual inspection systems for quality checks. These add-ons provide businesses with additional functionality and flexibility, making the ALFVS-12S a versatile choice for a range of packaging applications.

Selecting the right servo-controlled stick packing machine involves assessing your specific packaging needs based on factors such as product types, production volumes, and packaging formats. Here are some tips for making an informed choice:

lIdentify Your Product Requirements: Consider the types of products you need to package. Are they powders, granules, or liquids? Do they require special handling, such as dust recovery or precise filling? Understanding these requirements will help you select a machine that can accommodate your product characteristics.

lEvaluate Production Speed and Flexibility: Look for machines that offer high production speeds and can handle different configurations without extensive downtime for changeovers. Machines like the ALFVS-12S with multi-row configurations and customizable settings are ideal for businesses with diverse packaging needs.

lCompare Key Features and Performance Metrics: When comparing different servo-controlled stick packing machines, focus on features like precision filling, sealing quality, film handling, and cutting accuracy. Consider the total cost of ownership, including maintenance and energy consumption.

lConsult with Experts: Partnering with packaging technology experts, like those at Pharmapack, can help ensure that the selected machine aligns with your operational requirements and goals. Our team is dedicated to providing customized solutions tailored to your unique needs, backed by extensive industry experience.

Upgrading to a servo-controlled stick packing machine presents an opportunity to enhance your packaging line's efficiency, accuracy, and quality. With advanced technology, like the ALFVS-12S from Pharmapack, businesses can achieve higher production speeds, improved precision, and seamless adaptability across various product lines.

We invite you to explore Pharmapack's solutions and discover how our cutting-edge machines can elevate your packaging processes. For more information or to request a quote, please reach out to our team. Our experts are ready to guide you in selecting the perfect packaging solution to meet your business needs.