WORKING PRINCIPLE

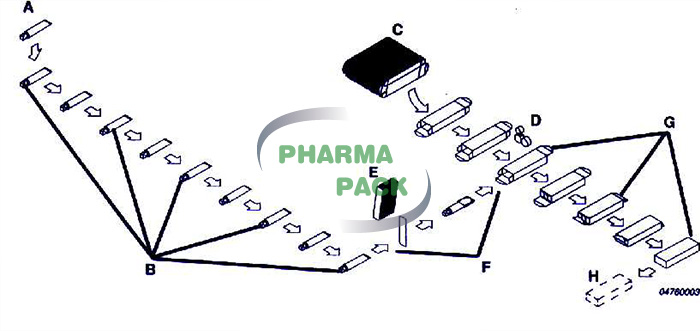

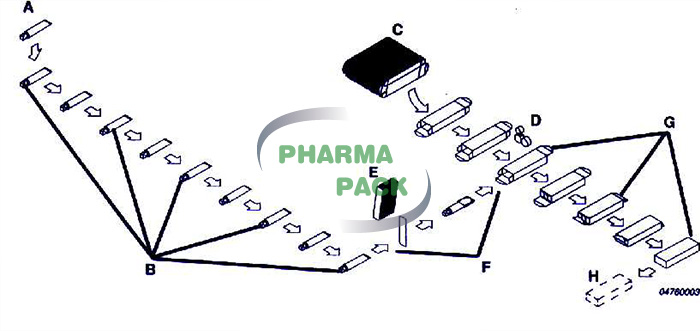

1. Product Feeding and Carton Synchronization

The product A is placed manually or automatically into the infeed conveyor B of the horizontal cartoning machine. On the conveyor, a sensor detects the presence of the product, allowing the carton to be automatically transferred from the magazine C, ensuring smooth synchronization in this automatic cartoning machine process.

2. Carton Coding and Leaflet Insertion

Each carton is squared and positioned at the marking station D, where a mechanical embossing system prints the code on the flap. It is then transferred to the filling section. The leaflet inserter of the pharmaceutical cartoning machine places a leaflet into the introduction zone F. When the product reaches the end of the bucket, the leaflet is automatically fed and pushed into the opened carton, ensuring precision and consistency typical of an intermittent cartoning machine.

3. Carton Closing and Flap Folding

The filled carton moves forward via the top and bottom toothed belt transport system, where a series of folders G fold the flaps to securely close the carton — a process optimized for stability in cartoner packaging machine operations.

4. Carton Ejection and Quality Control

At the exit station H, the cartonator packing machine automatically detects and ejects incomplete cartons, maintaining high reliability and quality assurance standards expected from a professional cartoning machine manufacturer.

FEATURES

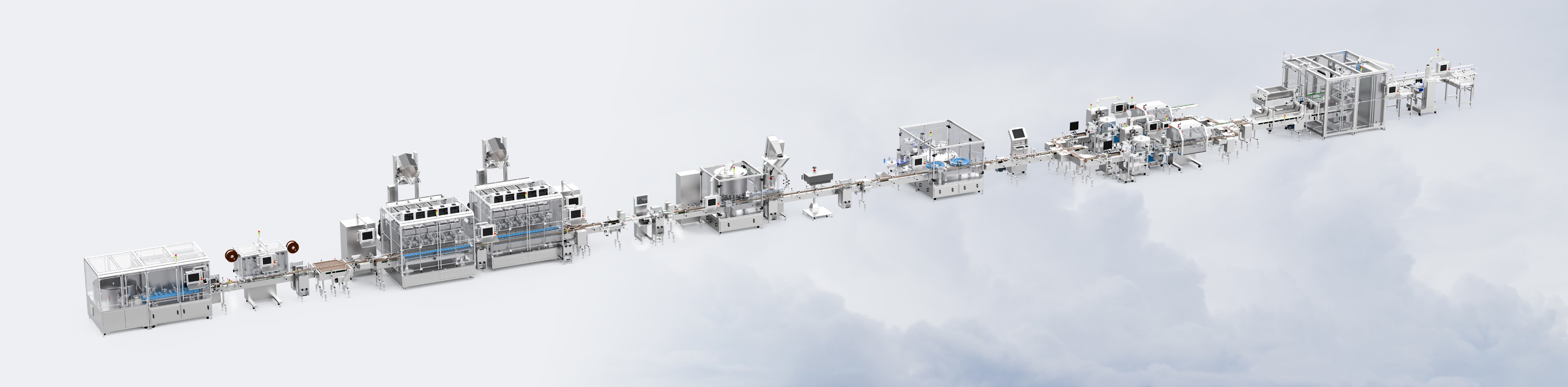

1. Compact and GMP-Compliant Design

The horizontal cartoning machine is designed in full compliance with GMP standards and current industrial safety regulations. Its compact structure and minimal footprint make it ideal for integration into modern pharmaceutical cartoning machine production lines.

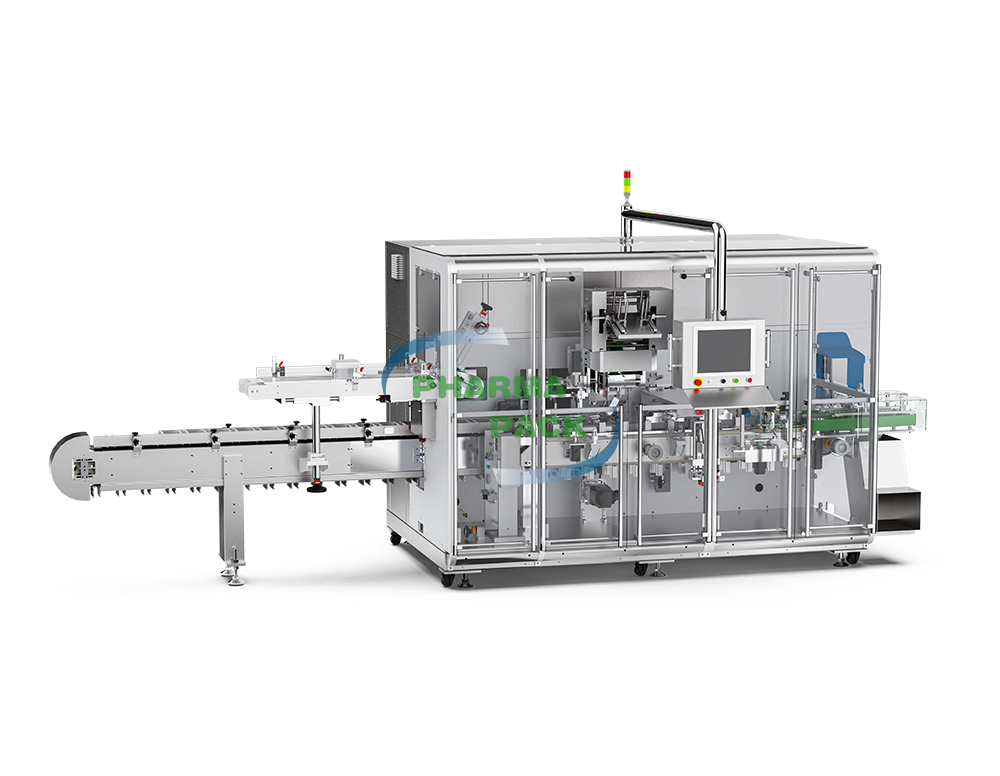

2. Open “Balcony” Structure for Easy Maintenance

Developed by Pharmapack, a leading cartoning machine manufacturer, this model adopts a “Balcony” design structure. The main and auxiliary drive components are mounted on one side of the conveying system, ensuring easy cleaning, maintenance, and format changeover. This open design also prevents dust and carton scraps from entering the drive mechanism, enhancing overall stability.

3. Scratch-Free Conveyor for Delicate Cartons

The scratch-resistant white toothed conveyor chain guarantees that cartons remain intact and unmarked during transfer. Even high-gloss or delicate cartons can be smoothly conveyed, making it an excellent choice for automatic cartoning machine supplier lines handling fragile or premium packaging.

4. Quick Changeover and Precision Adjustment

Equipped with a robust mechanical drive and a reliable product feeding system, this intermittent cartoner enables quick and tool-free changeover. Adjustments can be made precisely via a digital handwheel, supporting flexible operations in industrial environments.

5. Intelligent Control

The system features an intelligent PLC control and a liquid crystal touch-screen interface, improving efficiency in production and changeovers. As a professional cartoner packaging machine developer, Pharmapack ensures all electrical components, noise levels, and safety protection devices comply with international standards.

6. Versatile Carton Sealing and Insertion Options

This cartonator packing machine is suitable for both pre-glued cartons with rear or direct flap insertion. It can also be configured with a hot-melt glue sealing device or a mixed mode of flap insertion and glue sealing, meeting diverse application needs across pharmaceutical, cosmetic, and healthcare packaging industries.