WORKING PRINCIPLE

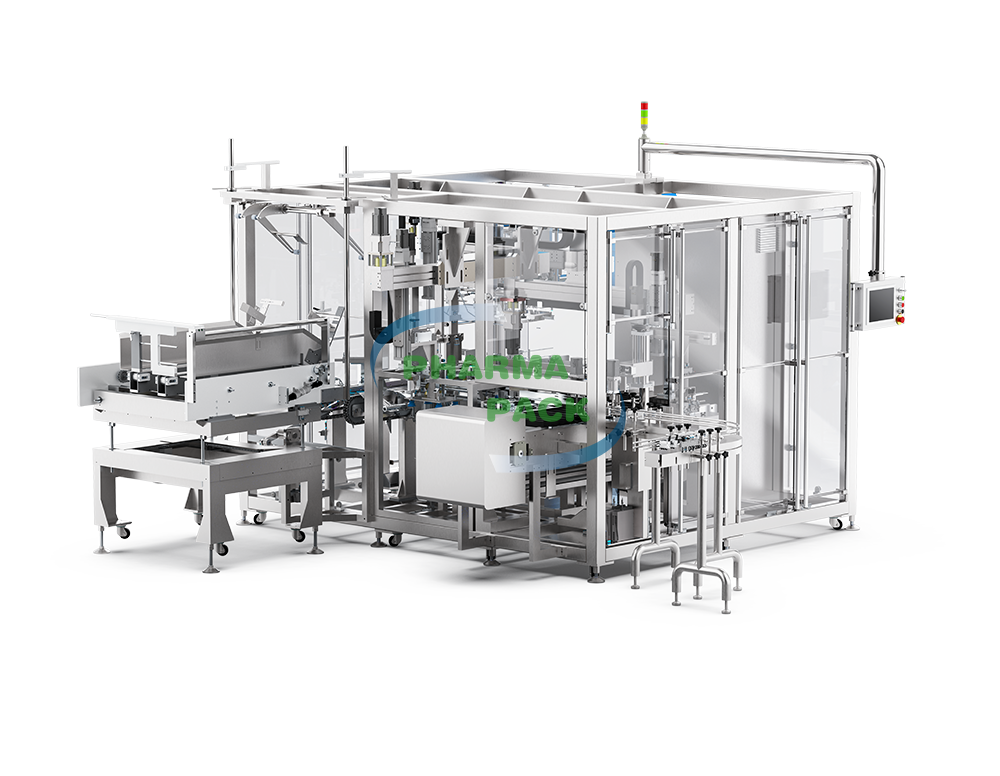

ONE-PIECE CASE PACKER is composed of a bottle feeding part, a bottle dividing part, a suction carton part, a folding and forming part, an adhesive spraying part, a pneumatic part and an electronic control part. According to customer packaging requirements, it uses single track for accurate grouping; At the same time, the case used for packaging is synchronously delivered under each group of products by the suction cardboard mechanism, and the final packaging of the product is completed by the coordination of the forming folding mechanism and the adhesive spraying device. The synchronization of each part is accomplished by several servo motors and mechanical adjustment synchronization so as to ensure the accuracy, quality and beautiful packaging of each group of products.

FEATURES

1.Quick adjustment to programmed package size.

2.Mechanical system has been simplified to a new electronic synchronous automation platform.

3.The combination of servo drives, electronic cams and compact embedded transmission systems simplify the wiring of the machine, reducing the size of the electrical cabinets and allowing the removal of most of the adjusting chains and their associated mechanical counters.

4.Higher accuracy and lower noise levels.

5.Accord with human body engineering operating experience; Less maintenance and even better sanitation; The optimized timing belt design represents updated, more hygienic, and lower maintenance costs. The thermoplastic polyurethane timing belt (FDA approved) greatly reduces potential dust, residual grease, and eliminates the necessary regular periodic chain adjustments and maintenance.

6.It is convenient for changeover, all adjustment points are equipped with knot adjuster, scale and variety specification table. When changeover, operators only need to adjust the set values in the table, which greatly saves time and is convenient and fast.

7.High quality electrostatic spraying treatment: bright equipment appearance, high adsorption, up to the processing level of imported equipment.

8.Closure cabinet design: in order to reduce to occupy the field of customer site and keep safe use of equipment.

9.Reasonable structure, easy operation and maintenance: the machine is composed of reasonable mechanical structure, reliable pneumatic device and advanced self-control technology. It is with high level of configuration, closed operation, sturdy structure, easy operation and maintenance ,also Reasonable structure, easy operation and maintenance: the machine is composed of reasonable mechanical structure, reliable pneumatic device and advanced self-control technology, with high level of configuration, closed operation, strong structure, easy operation and maintenance, also, is in line with industrial safety regulations.