System Description

High-speed tablet counter machine with a capacity of 400 bottles per minute.

Simultaneous filling of bottles while in motion — bottles need not stop for filling.

Each module head consists of eight channels for stable counting.

Optional in-built tablet and capsule counter inspection system.

The automatic counter LFM-32 uses the Pharmapack PP-Modular Series Continuous Motion counting system. The pharmaceutical tablet counter supports flexible configuration with 4, 6, 8, or 10 module heads, achieving an output of up to 400 bottles per minute.

Designed by experienced pharma packaging suppliers, it integrates easily into a bottle packaging line with a compact structure and minimal change parts. The tool-less changeover makes operation simple and quick. With no hidden tablet traps, cleaning is fast, efficient, and hygienic — ideal for automatic capsule filling machine manufacturer standards.

Main Features

Fully modular tablet counter machine design with unique, separated module parts for flexible configuration.

Easy operation with minimal settings, ideal for pharma packaging suppliers and production environments.

Compact structure with a small footprint allows seamless integration into any packaging line.

Simultaneous counting and bottling improve overall efficiency, supporting pharmaceutical tablet counter performance.

Three-grade vibratory plates with 8 channels ensure stable separation for accurate counting with no overlap.

Fault auto-diagnosis and real-time monitoring alarm system with storage for up to 100 sets of product parameters.

Precise bottle rejection mechanism ensures counting accuracy in tablet and capsule counter operations.

Suitable for tablets/capsules from 1.5 mm to 21 mm in length, adaptable to diverse production needs.

Compatible with containers of various shapes, including round, oval, square, and rectangular types up to 160 mm height.

All electronic tablet counter systems utilize 21 CFR Part 11 compliant software for quality and traceability.

Solution

Solution

We know that every business is different. That’s why we provide customized tablet counter machine solutions designed to meet unique client requirements through advanced automation.

Industry Application

Model: LFM-32

Function: A patented tablet and capsule counter for high-speed counting of pills and capsules.

Industry: Pharmaceutical, healthcare, food.

How Pharmapack automatic capsule counting machine can help your production:

The servo-controlled system reduces production noise and operating costs by minimizing spare parts. Designed according to GMP norms, the system ensures precision and reliability. The intuitive touch screen IPC simplifies operation, enhancing performance for pharmaceutical filling machine manufacturers and end users.

Customized Services

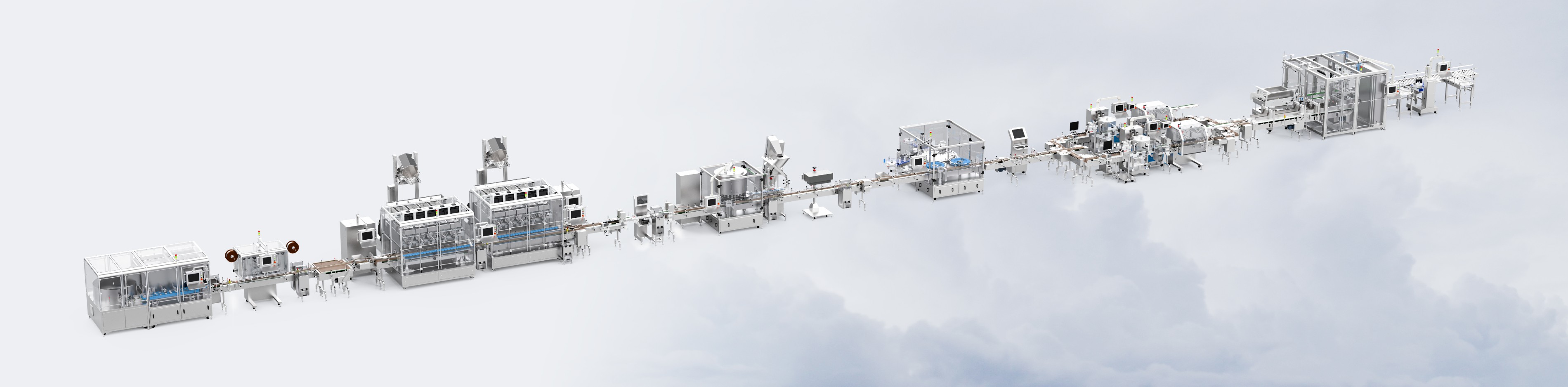

Pharmapack provides turnkey packaging solutions tailored to each customer’s production needs. As trusted pharma packaging suppliers, we offer customized support based on detailed data analysis.

Professional pre-sales and after-sales service centers are located in Asia, Europe, and North America.

Solutions covering system design, commissioning, maintenance, and equipment upgrades.

Dedicated 24-hour online support team for automatic capsule filling machine manufacturer and tablet counter machine users worldwide.

Cases

At present, Pharmapack electronic tablet counter has been exported to more than 30 countries and regions worldwide. We have successfully delivered complete line installations for many leading pharmaceutical companies.

International:

Pfizer, GSK, Johnson & Johnson, Abbott, Sanofi, AstraZeneca, Baxter, Mars, Wrigley, Perfetti, L’Oréal, AVON.

Domestic:

TongRenTang, Salubris, Jilin AoDong, North China Pharmaceutical Company, Harbin Pharmaceutical Group, Yunnan Baiyao, Guangzhou Pharmaceuticals, Yangtse River, Tasly Pharma, Infinitus, BY-HEALTH, etc.

As a trusted automatic capsule counting machine and capsule counter machine provider, Pharmapack continues to expand our global footprint as one of the leading pharmaceutical filling machine manufacturers supporting large-scale automated packaging projects.

Why choose Pharmapack Machine

Experienced R&D Group Pharmapack congregates advanced technology in the world to supply the most advanced and guaranteed technical support for our customers as a professional tablet counter machine and pharmaceutical filling machine manufacturers. | One-stop Service System As one of the leading pharma packaging suppliers, Pharmapack provides complete “turn-key” packaging solutions including automatic capsule counting machine and tablet and capsule counter integration for every customer.

|

Industry-leading Technology Our electronic tablet counter uses a new servo control system with self-detection to replace the old cylinder, keeping the capsule counter machine free of dust influence, offering more stability, longer lifespan, and lower maintenance cost. | Excellent Quality Control Tested by internationally certified companies, Pharmapack equipment—including automatic capsule filling machine manufacturer standards—has passed CE, UL, CSA certification and complies with GAMP, FDA (CFR21), cGMP, and TGA regulations. |