In the pharmaceutical industry, maintaining strict adherence to GMP standards is essential for reliable production. As pharma packaging machinery manufacturers, we at Pharmapack design and deliver equipment that supports efficient operations while meeting regulatory requirements. By combining advanced engineering, rigorous quality control, and a robust service network, we provide solutions that help pharmaceutical companies optimize their production processes without compromising compliance. Our focus on innovation and practical usability ensures that clients receive machinery suited to the specific demands of modern pharmaceutical manufacturing.

To maintain GMP compliance, we focus on precise engineering and robust testing at every stage. Our Italian branch office, consisting of more than 10 R&D specialists, works closely with the Guangzhou headquarters, where over 70 senior technical engineers oversee the integration of pharma packaging technology from multiple international sources. The design of our smart bottle, inspection, flexible, and secondary packaging lines incorporates modular concepts, which allow customization from one module to many. This flexibility ensures that pharmaceutical production facilities can operate efficiently without compromising quality or compliance standards. Each unit is subjected to comprehensive quality control procedures, ensuring that equipment performance remains consistent and aligned with GMP requirements.

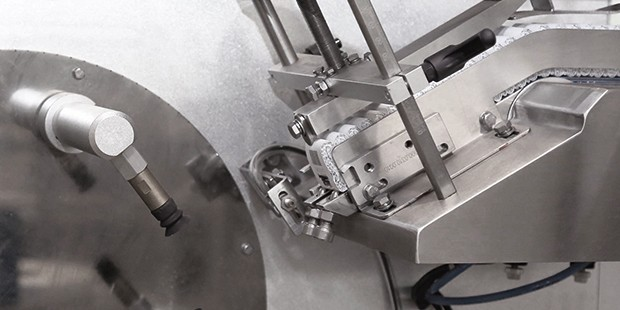

As an automatic packing machine manufacturer, we continually refine our servo control technology to enhance stability, longevity, and maintenance efficiency. New servo systems with self-detection replace traditional cylinders, reducing dust accumulation and improving operational reliability. By implementing these advanced mechanisms, we provide machinery that meets the rigorous demands of pharmaceutical manufacturers while also enabling safer, cleaner, and more efficient production environments. Our clients benefit from lower maintenance costs and more predictable machine performance, which is critical when operating under strict GMP guidelines.

One of the core advantages of choosing Pharmapack is our one-stop service system. As pharma packaging machinery manufacturers, we supply full turn-key solutions, ensuring that smart packaging lines are delivered, installed, and supported with minimal disruption to client operations. From initial consultation to after-sales support, we coordinate technical assistance, spare parts availability, and training programs to help pharmaceutical companies maintain uninterrupted production. This holistic approach ensures that our machinery not only complies with GMP standards but also integrates seamlessly into existing workflows.

We continuously monitor changes in pharmaceutical regulations and production requirements to ensure that our pharma packaging technology remains current and effective. By combining rigorous research, precise engineering, and comprehensive support, Pharmapack reinforces its role as a trusted partner for pharmaceutical manufacturers seeking reliable and compliant packaging solutions. Our dedication to quality and operational excellence ensures that clients receive machinery capable of sustaining both productivity and regulatory adherence.