In the pharmaceutical industry, where round bottles are widely used for medications like tablets, capsules, and liquids, specialized equipment is needed to ensure efficient, accurate labeling. This is where a round bottle machine comes in—a dedicated labeling solution designed to handle the unique challenges of applying labels to cylindrical containers. At Pharmapack, as a leading labeling machine manufacturer, we engineer our round bottle machines to meet the strict standards of pharmaceutical production, combining precision, speed, and compliance. Understanding what a round bottle machine is and how it works is essential for businesses looking to optimize their labeling process for round containers.

Defining a Round Bottle Machine: Core Purpose and Design

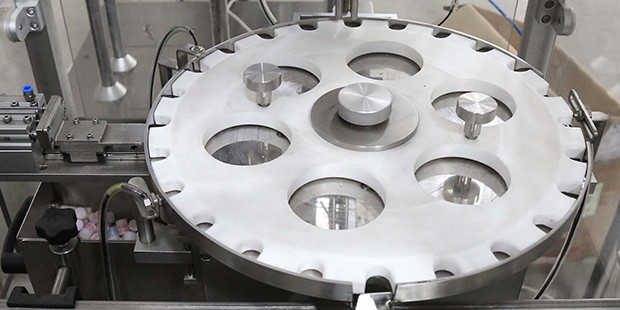

A round bottle machine is a type of automatic labeling equipment specifically designed to apply labels to round or cylindrical bottles—one of the most common container shapes in pharmaceuticals. Unlike flat labeling machines (which handle square or rectangular containers), round bottle machines address the unique challenge of wrapping labels evenly around a curved surface without wrinkles, bubbles, or misalignment. Our machines feature a specialized design that includes rotating rollers or belts to spin the bottle as the label is applied, ensuring the label adheres smoothly and uniformly.

Key Features of Pharmapack’s Round Bottle Machine

Our round bottle labeling machine stands out for its industry-specific features that prioritize precision, efficiency, and reliability. First, it offers ±0.2mm labeling accuracy—critical for pharmaceutical applications where label placement directly impacts the visibility of dosage instructions, expiration dates, and regulatory information. Second, it supports high-speed production, with a maximum output of 200 BPM (bottles per minute)—ideal for large pharmaceutical groups with high-volume needs. Third, it includes smart operation features like quick changeovers (allowing you to switch between bottle sizes in minutes) and up to 50 settings memory (for storing frequently used configurations), reducing downtime and simplifying operator training.

Why Pharmaceutical Companies Choose Round Bottle Machines

For pharmaceutical companies, using a dedicated round bottle machine offers clear advantages over generic labeling equipment. First, it eliminates the inefficiencies of manual labeling—such as slow speed, inconsistent placement, and high error rates—freeing up staff to focus on more critical tasks. Second, it ensures compliance with strict industry regulations: our machines are built to meet GMP and 21CFR standards, and their track-and-trace capabilities allow for easy data logging during audits. Third, it improves product quality and safety: by ensuring labels are applied correctly and securely, round bottle machines reduce the risk of label peeling (which could lead to misidentification of medications) and ensure all critical information is visible to healthcare providers and patients. Finally, it offers long-term value: our machines are designed for durability, with low maintenance requirements and the ability to adapt to changing production needs (like new bottle sizes or label materials).

Conclusion

A round bottle machine is a specialized, automated labeling solution designed to handle the unique needs of round or cylindrical pharmaceutical bottles—offering precision, speed, and compliance that generic equipment cannot match. At Pharmapack, as a trusted labeling machine manufacturer, our round bottle labeling machine is engineered to meet the strictest pharmaceutical standards, with features like high accuracy, fast production speeds, and zero-defect inspection. Whether you’re a small facility or a large pharmaceutical group, our round bottle machine can streamline your labeling process, reduce errors, and support your growth.