In the fast-paced world of cosmetic packaging, production efficiency is a top priority. As a company, we at Pharmapack understand the challenges that arise from carton jams during packaging processes. By integrating advanced anti-jamming features, cartoning machine suppliers like us help cosmetic manufacturers maintain smooth and uninterrupted production lines. Our approach focuses not only on minimizing downtime but also on protecting the integrity of both cartons and products.

Advanced Anti-Jamming Technology in Modern Cartoners

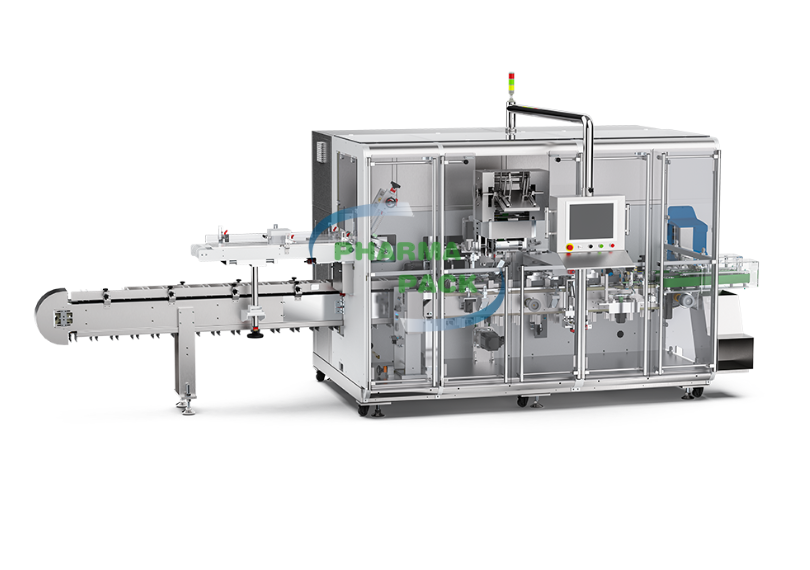

One of the key advantages offered by cartoning machine manufacturers is the incorporation of sophisticated anti-jamming mechanisms in machines such as the LFBI-10 Intermittent Horizontal Cartoner. This model is specifically designed to handle cosmetic products with varying sizes, from 110~195 mm in length to 10~75 mm in height, and accommodates cartons sized 115~200 mm in length, 40~130 mm in width, and 15~80 mm in height. Anti-jamming features include precise servo control with self-detection capabilities, which automatically adjusts operations if a carton or product is misaligned. This reduces the risk of stoppages and ensures continuous packaging without manual intervention. By adopting these innovations, Pharmapack helps our clients avoid costly interruptions and maintain a consistent production flow.

Modular Designs for Flexible Packaging Solutions

Another important feature highlighted by cartoning machine suppliers is modular machine design. Our LFBI-10 model employs a multiple modular design concept, allowing configurations from 1 to N to suit different cosmetic product requirements. This modularity ensures that each section of the machine operates harmoniously, further reducing the likelihood of jams. Additionally, the new flapper system, free from dust interference, contributes to smoother product movement and lower maintenance needs. With a maximum production speed of up to 100 pieces per minute, depending on the carton size and packed product, our machines can keep up with high-volume demands while maintaining operational stability.

Benefits of Working with Experienced Cartoning Machine Manufacturers

At Pharmapack, we combine global R&D expertise with over two decades of hands-on engineering experience. Our Italian branch and Innocentre headquarters bring together more than 80 technical specialists, ensuring that every machine we supply incorporates the latest anti-jamming technologies. Cartoning machine suppliers that invest in research, rigorous quality control, and field-tested engineering provide cosmetic companies with reliable solutions, reducing the likelihood of production losses and improving overall efficiency. Our one-stop service system, covering smart bottle, inspection, flexible, and secondary packaging lines, guarantees that clients receive fully integrated and optimized packaging solutions.

Efficient cosmetic packaging depends on the reliability and intelligence of cartoning machines. By choosing Pharmapack and collaborating with expert cartoning machine manufacturers, companies gain access to machines equipped with advanced anti-jamming features, modular designs, and smart servo control technologies. These innovations minimize production disruptions, protect product quality, and ensure smooth operation in high-demand environments. Investing in these systems not only improves efficiency but also supports a scalable, future-ready packaging process.