In the pharmaceutical packaging industry, ensuring stability and cleanliness during high-speed cartoning is crucial—especially for inhalation formulations that involve fine powders or aerosols. At Pharmapack, we understand that powder or aerosol reflux during continuous packaging not only affects product quality but can also cause equipment contamination and production delays. This is why our engineering team has developed a specialized anti-backflow design that enhances the performance of our continuous cartoning machines, ensuring smooth, safe, and efficient operation for every batch.

Challenges of High-Speed Cartoning for Inhalation Products

Inhalation formulations require delicate handling. The small particle size and lightweight nature of powders or aerosols often make them susceptible to reverse airflow during high-speed loading. Traditional mechanical systems lack the precision to control pressure changes, leading to leakage, contamination, or incomplete sealing. Recognizing these challenges, Pharmapack integrates advanced servo control and anti-backflow mechanisms into our cartoning machine manufacturers solutions, helping pharmaceutical producers maintain high production efficiency while protecting product integrity.

The Anti-Backflow Solution in Continuous Cartoning

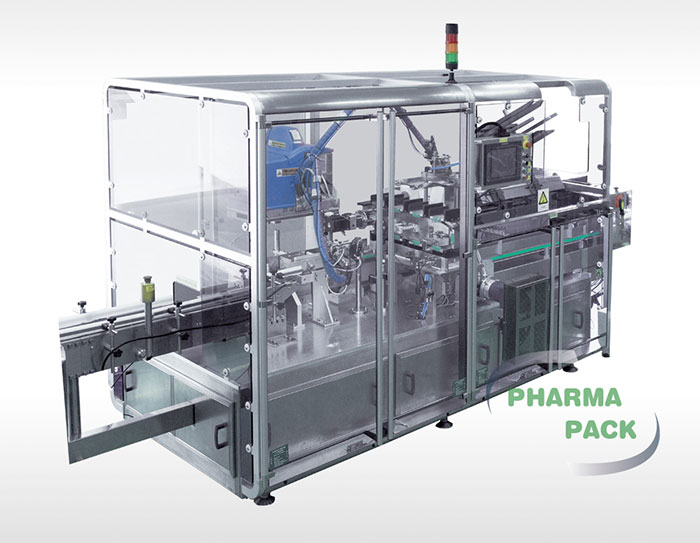

Our latest innovation—the LFBI-06 Trays and Display Box Packing Machine—illustrates how intelligent design can eliminate reflux issues. The LFBI-06 operates at a maximum speed of 60 cartons per minute, delivering exceptional consistency across various carton and bottle sizes. Through an optimized air control system and precisely tuned sealing process, the machine prevents powder or aerosol from re-entering the loading area. The advanced servo-driven flapper mechanism minimizes dust impact, extends lifespan, and lowers maintenance costs, ensuring that continuous cartoning machines maintain long-term reliability in demanding pharmaceutical environments.

This anti-backflow feature is not a standalone improvement; it is part of Pharmapack’s larger engineering philosophy—combining mechanical precision with intelligent control. Our modular design concept allows customization from single to multiple production lines, helping manufacturers achieve efficient, scalable operations without compromising hygiene or quality.

Smart Integration for Safer and Cleaner Packaging Lines

Beyond its anti-backflow function, the LFBI-06 also integrates seamlessly into smart bottle packaging and inspection lines. With its 10kW power system and stable operation under 0.4–0.8MPa air pressure, it supports pharmaceutical plants that require both flexibility and accuracy. The machine’s compact 3250mm by 1500mm structure makes it suitable for cleanroom environments, while the automated monitoring system reduces human intervention. Through these innovations, Pharmapack enables our clients to achieve a higher level of automation and process control—critical factors for modern cartoning machine manufacturers striving for GMP compliance.

Reliable, Efficient, and Future-Ready

At Pharmapack, we believe that true innovation means solving real production challenges. The anti-backflow design in our continuous cartoning machines represents a step forward in pharmaceutical packaging safety, especially for sensitive inhalation formulations. With the LFBI-06 and our complete range of intelligent cartoning solutions, we continue to provide one-stop, turnkey systems that ensure efficiency, reliability, and cleanliness. We welcome global pharmaceutical manufacturers to partner with us and experience how Pharmapack technology can transform high-speed packaging into a safer, smarter, and more sustainable process.