When choosing a pharmaceutical packaging machinery manufacturer, it is essential to understand the common pitfalls that can lead to costly mistakes or suboptimal results. Many factors influence this decision, from the machinery's quality and performance to its reliability and the manufacturer’s ability to provide timely support. In this article, we will discuss some key considerations when selecting a supplier of packaging equipment in pharmaceutical industry to ensure you make an informed decision that supports your production goals.

Choosing the Right Manufacturer

Selecting the right manufacturer for pharmaceutical packaging machinery is crucial for ensuring efficient production. The first common pitfall is underestimating the importance of after-sales service. A manufacturer who can provide comprehensive technical support, training, and spare parts availability will help minimize production downtime. This is particularly important for complex machinery that requires regular maintenance and occasional troubleshooting. Therefore, always ensure that the manufacturer offers reliable after-sales service and technical assistance when needed.

Assessing the Technology and Innovation

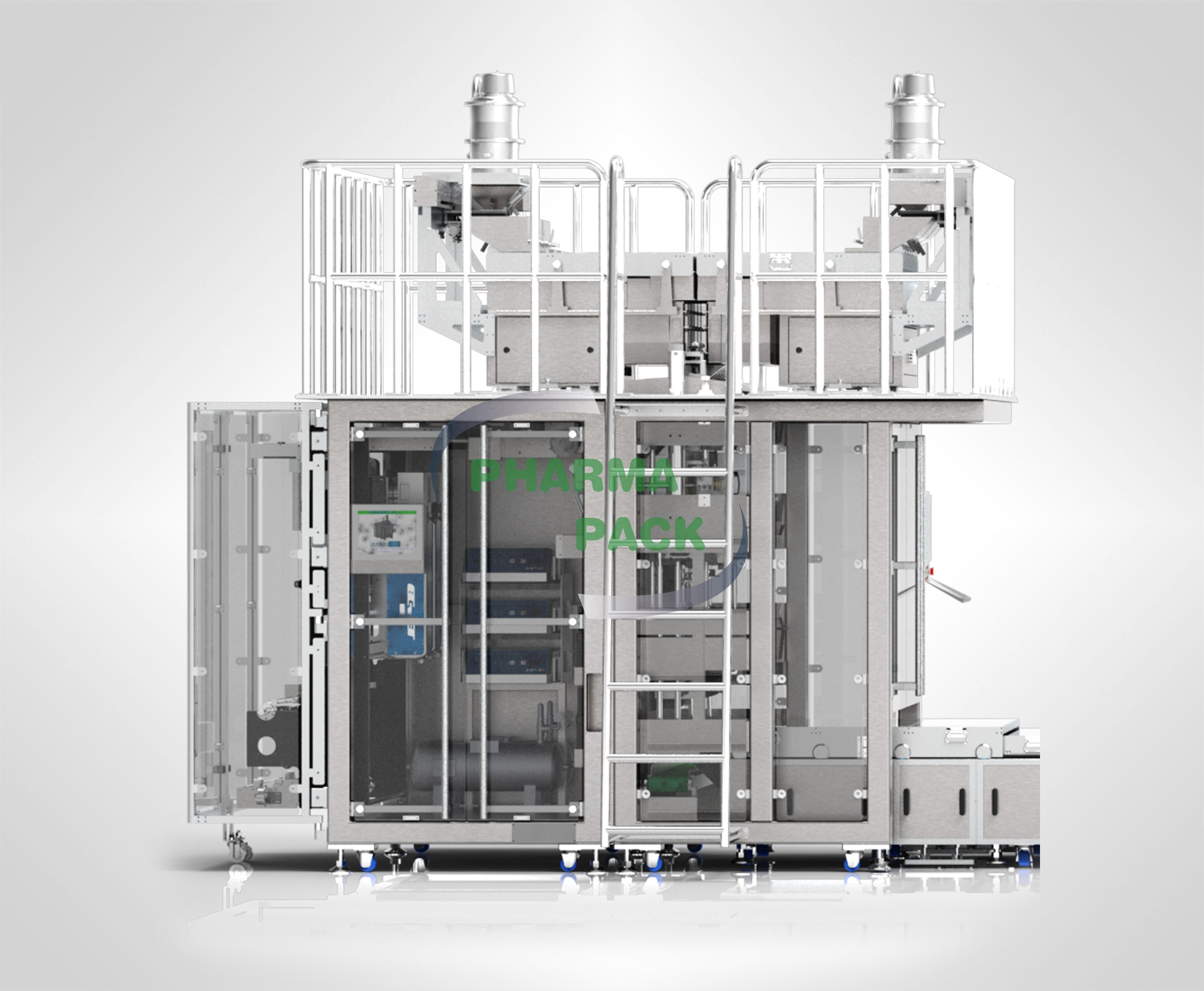

Another key consideration when selecting packaging machinery is the level of innovation incorporated into the equipment. For instance, Pharmapack offers advanced machinery such as the ALFVS-12S Servo-controlled Stick Packing Machine. This model features high-precision I-Mark remote control, servo drive, and automatic adjustments to ensure precision packaging and minimal noise. Choosing a manufacturer that prioritizes the latest technology can help you avoid outdated systems that might lead to inefficient operations. Additionally, technology improvements such as servo control and automatic film adjustments improve efficiency, lower energy costs, and reduce downtime.

The Importance of Quality Control and Certifications

A major pitfall when selecting packaging equipment in pharmaceutical industry is neglecting to verify the manufacturer's adherence to strict quality standards. Ensure that the machinery complies with industry regulations and certifications, such as ISO certifications or GMP (Good Manufacturing Practices). This guarantees the equipment meets safety standards and is reliable over the long term. Pharmapack’s products, like the ALFVS-12S, are designed with these factors in mind, offering stability, low noise, and high precision, ensuring your packaging process is up to the highest standards.

Evaluating Efficiency and Cost

While cost is always a factor, it should not be the primary driver of your decision-making process. A low initial price might seem attractive, but the long-term operational costs, maintenance requirements, and downtime may end up costing more. For example, the ALFVS-12S Servo-controlled Stick Packing Machine is designed to provide high-speed, high-productivity results with low failure rates. When evaluating costs, consider not only the upfront price but also the machine’s efficiency, reliability, and serviceability over time.

Conclusion

In conclusion, selecting the right pharmaceutical packaging machinery manufacturer requires careful consideration of several factors. Avoid common pitfalls such as inadequate after-sales support, outdated technology, and neglecting quality control standards. By choosing a manufacturer that offers advanced technology, robust support, and efficient machinery, you can ensure smooth operations and meet the packaging needs of your pharmaceutical production. Pharmapack, with its commitment to quality and technological innovation, stands out as a reliable partner for businesses seeking high-performance packaging solutions.