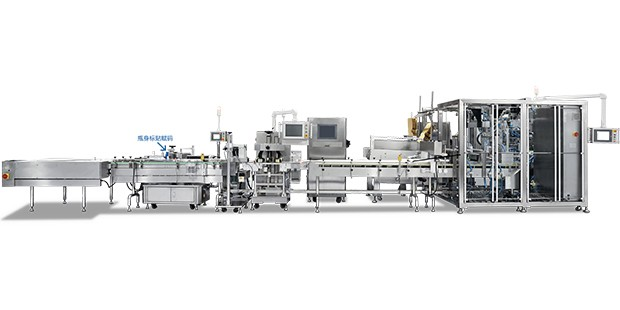

Quick changeovers are crucial for optimizing production lines, particularly in industries where speed and flexibility are paramount. Pharmapack, with its cutting-edge technology, offers solutions that address this challenge effectively. The company’s advanced machinery, such as the bottle unscrambler machine and automatic bottle labeler machine, is designed to minimize downtime and ensure smooth transitions between different production runs. These innovations play a significant role in enhancing operational efficiency while maintaining high-quality standards, allowing manufacturers to meet market demands without compromising on performance.

Efficient Design for Quick Changeovers

To stay competitive, manufacturers must focus on minimizing changeover times without sacrificing quality or output. Pharmapack has introduced highly efficient systems designed with quick changeovers at their core. The bottle unscrambler machine is equipped with modular components, allowing quick adjustments for different bottle types and sizes. This modularity ensures that a changeover can be done swiftly, minimizing downtime and increasing overall productivity. Whether it’s a small batch or a large-scale production, this machine provides the flexibility needed for diverse packaging needs.

In addition to the bottle unscrambler machine, Pharmapack’s automatic bottle labeler machine also offers impressive flexibility, enabling fast label changes to suit different products. Label changes can be made without disrupting the production flow, which is particularly beneficial in industries where product lines are frequently adjusted. For manufacturers, this means minimal downtime and a significant reduction in manual labor, both of which directly contribute to improved operational efficiency.

Advanced Features for Seamless Integration

Pharmapack ensures that its equipment not only delivers on quick changeovers but also integrates seamlessly with other advanced systems for enhanced functionality. A prime example is Pharmapack’s Track and Trace System for bottle packaging lines. This system is equipped with advanced features such as serialization, weight checking, coding, and tamper-evident labels, all designed to guarantee the safety and traceability of products. Each product is equipped with a unique identification code, making it easier to trace its journey through the production line.

The Track and Trace System also helps reduce errors during changeovers. With real-time data synchronization, it ensures that every product is correctly identified, preventing mix-ups or mislabeling. Furthermore, this system works in tandem with the automatic bottle labeler machine, ensuring that all products are labeled according to industry standards without slowing down production. These features not only enhance the accuracy of each changeover but also ensure that the entire production process is streamlined and compliant with relevant regulations.

Conclusion

In conclusion, Pharmapack is committed to solving the challenge of quick changeover times with advanced, flexible, and efficient equipment. By focusing on modular machines such as the bottle unscrambler machine and automatic bottle labeler machine, Pharmapack provides manufacturers with the tools they need to improve productivity while maintaining product quality. The integration of advanced systems like the Track and Trace System ensures that each changeover is not only quick but also accurate, minimizing errors and ensuring regulatory compliance. Pharmapack’s dedication to innovation and quality makes it a trusted partner in the packaging industry, offering reliable solutions to meet the demands of a fast-paced market.