In the highly competitive field of packaging machinery, selecting the right cartoning machine manufacturers is crucial for ensuring efficient, reliable, and scalable production. A world-class supplier like Pharmapack stands out not only due to the high quality of their products but also through their comprehensive service and technological expertise. While local providers may offer cost-effective solutions, they often lack the advanced features, industry knowledge, and robust support that leading manufacturers provide. Let's explore what sets the top suppliers apart from others and why working with a global supplier can make a significant difference in the long run.

Cutting-Edge Technology and R&D Expertise

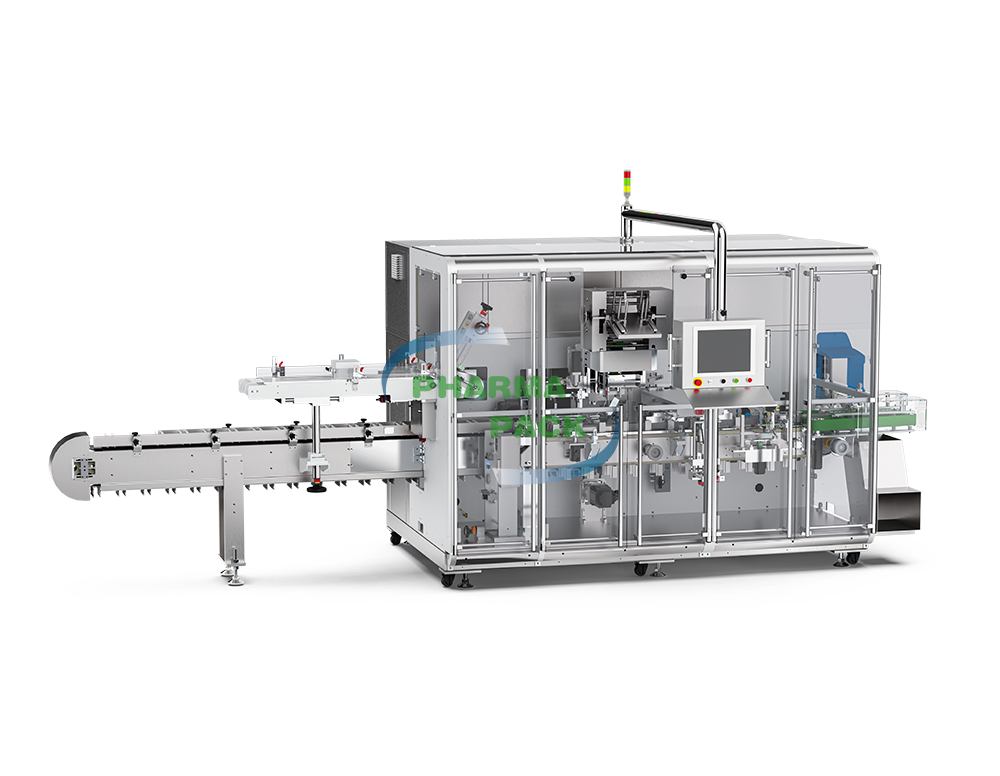

One of the key differentiators between global and local cartoning machine manufacturers is their commitment to research and development. Leading suppliers invest heavily in innovation, offering machines like the automatic cartoner machine that incorporate advanced features such as sophisticated PLC controllers, modular designs, and user-friendly interfaces. Pharmapack, for example, is known for their high-tech solutions like the LFBI-10 Intermittent Horizontal Cartoner, which not only conforms to GMP standards but also boasts a "Balcony" structure for easy maintenance and cleaning. This design minimizes downtime, as it allows for simple inspections and product changeovers. Additionally, the advanced technology ensures that each machine can handle a variety of packaging requirements, from delicate pharmaceutical products to cosmetics, with ease and precision.

Global Standards and Regulatory Compliance

World-class automatic cartoner machine suppliers adhere to strict international standards, ensuring that their products meet global regulatory requirements. Pharmapack stands out by offering solutions that are not only efficient but also compliant with various industrial safety rules. Their machines, like the LFBI-10, are designed to be compact yet powerful, utilizing scratch-resistant conveyor chains that ensure smooth, reliable carton handling. This is particularly important for industries like pharmaceuticals and cosmetics, where product integrity, hygiene, and safety are paramount. In contrast, local providers may not always prioritize compliance with global standards, which could lead to issues with product quality or regulatory approvals.

Seamless Integration and Versatility

Another major advantage of working with global suppliers is the ease of integration and adaptability of their machines. The LFBI-10, for instance, features a modular design that simplifies product changeovers without requiring additional tools or downtime. This flexibility is vital in high-demand environments where production runs vary, and rapid response times are crucial. Pharmapack's automatic cartoner machine solutions are engineered to seamlessly integrate into existing production lines, ensuring minimal disruption. Furthermore, the company offers a one-stop service system, which includes everything from initial consultation and installation to after-sales support, ensuring that customers can rely on continuous guidance and support throughout the lifespan of their machinery.

Conclusion

Choosing a cartoning machine manufacturer with a proven track record, like Pharmapack, offers significant advantages over local suppliers. From advanced technological features and dedicated research and development to strict regulatory compliance and seamless integration, world-class suppliers ensure that their customers receive not only the best machinery but also the ongoing support necessary for long-term success. The LFBI-10 Intermittent Horizontal Cartoner is a perfect example of how top-tier manufacturers focus on efficiency, safety, and ease of use, making it an ideal solution for businesses in the pharmaceutical, food, and cosmetics industries. By partnering with a leader like Pharmapack, companies can ensure their production lines remain at the forefront of innovation and quality.