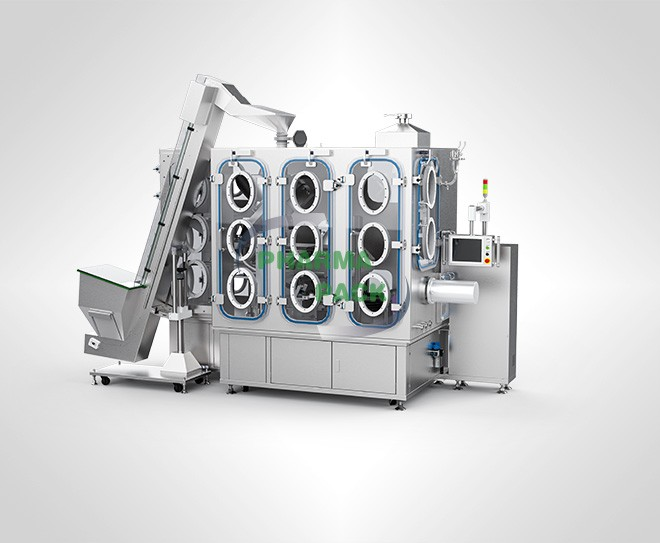

In the fast-paced world of manufacturing, optimizing production efficiency is crucial for businesses to meet high demand and stay competitive. Pharmapack introduces the LF-0601CR Monoblock Filling Machine, a cutting-edge solution designed to revolutionize bottle processing operations. With its streamlined workflow and advanced automation capabilities, the LF-0601CR offers unparalleled efficiency and precision. From desiccant insertion to quality control, counting, filling, and capping, this monoblock filling machine is a game-changer for industries requiring reliable and efficient packaging solutions.

Streamlined Workflow for Seamless Bottle Processing

The LF-0601CR Monoblock Filling Machine is engineered with a streamlined workflow to ensure efficient and seamless bottle processing. Starting at the turntable infeeding station, bottles are smoothly transported via a conveyor to the desiccant station. The turntable guides the bottles to the precise location for desiccant insertion, minimizing handling errors and maximizing efficiency. This optimized workflow minimizes downtime and allows for high-speed production, significantly enhancing overall operational efficiency.

Accurate Desiccant Insertion and Robust Quality Control

Ensuring accurate desiccant insertion is a critical aspect of many industries, such as pharmaceuticals and food packaging. Our LF-0601CR excels in this area with its advanced desiccant inserter. The machine precisely cuts and fills desiccants into each bottle, guaranteeing consistent and reliable results. Following desiccant insertion, the bottles proceed to the desiccant detection station, where a thorough quality control check takes place. Any bottles with improperly inserted or missing desiccants are promptly rejected, maintaining the highest quality standards.

Efficient Counting, Filling, and Capping Operations

Our LF-0601CR Monoblock Filling Machine continues to impress with its exceptional counting, filling, and capping capabilities. At the counting and filling station, the machine accurately counts the bottles and fills them with the desired product. This precise process ensures consistency and avoids wastage, optimizing resource utilization. After filling, the bottles undergo another quality control inspection, where any defective or compromised bottles are efficiently rejected. Finally, the capping stage incorporates a state-of-the-art cap sorting unit that selects and places the correct caps onto the bottles, ensuring secure sealing and product integrity.

Conclusion

Pharmapack's LF-0601CR Monoblock Filling Machine is a game-changer for businesses seeking to boost production efficiency and maintain exceptional quality control. With its streamlined workflow, accurate desiccant insertion, and efficient counting, filling, and capping operations, this machine offers a comprehensive solution for various industries. By investing in our LF-0601CR, businesses can significantly enhance their operational efficiency, reduce labor costs, and meet high-demand requirements. Stay ahead of the competition and deliver superior products with ease using the Pharmapack LF-0601CR Monoblock Filling Machine, a true innovation in bottle processing technology.