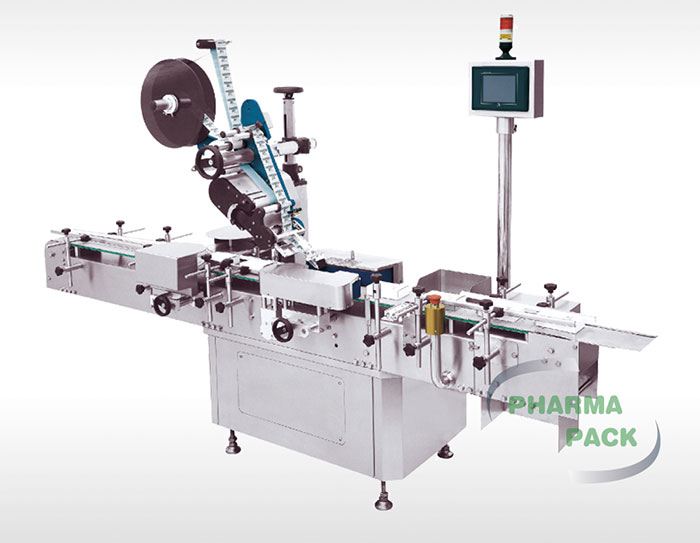

At the heart of Pharmapack's automatic labelling machine is a state-of-the-art label dispenser powered by a servo motor. This implementation brings unparalleled accuracy to label dispensing, reaching an impressive precision of 0.2mm. The closed-loop control ensures that every label is precisely placed, meeting the highest standards in the industry. This level of accuracy is crucial, especially in pharmaceutical and packaging environments where precision is non-negotiable.

Multidimensional Adaptability:

Pharmapack's label dispenser goes beyond mere precision; it embraces versatility. The machine features multidimensional and angle adjustment capabilities, allowing it to seamlessly adapt to a diverse range of labeled objects. This adaptability is a game-changer for industries dealing with various product shapes and sizes. Whether it's a cylindrical pharmaceutical bottle or a uniquely shaped package, Pharmapack's automatic labelling machine ensures a perfect fit every time.

Advanced Control System:

The core of efficiency lies in control, and Pharmapack understands this well. The automatic labelling machine is equipped with a special control system based on the MCU multi-point control unit. This not only enhances control accuracy but also simplifies the handling of complex labeling tasks. The labeller seamlessly integrates into online processes, receiving control signals from upper machines. The user-friendly human-machine interface on the touch screen makes operation intuitive and efficient, ensuring a smooth and hassle-free experience.

Parameter Storage Function:

Pharmapack's automatic labelling machine takes a proactive approach to efficiency with its parameter storage function. The labeler can store up to 50 groups of parameter information. This feature proves invaluable when dealing with a variety of products, significantly reducing the time required for machine debugging during product transitions. The ease of adjusting stored parameters enhances overall operational efficiency.

Label Management Function:

Keeping track of label usage is crucial for production planning and resource management. Pharmapack's automatic labelling machine includes a label management function that automatically counts the quantity of labels used. The operation interface displays both the used and remaining label quantity, providing operators with real-time information to streamline the production process.

Adjustable Photo Sensibility:

The label sensor's photo sensitivity is a key feature that enhances the machine's adaptability. It can be adjusted to accommodate labels with varying transmissivity, eliminating the need to readjust the sensor when switching between labels of different lengths. This flexibility simplifies the production process and contributes to the overall efficiency of the labelling operation.

Interference-Free Operation:

Pharmapack prioritizes precision in label application by ensuring that external factors do not interfere with the machine's sensors. The object-detecting sensor and label sensor are designed to operate seamlessly without being affected by external light, ultrasonic waves, or other interference sources. This precise detection mechanism guarantees error-free printing and eliminates the risk of mislabeling, even in challenging working environments.

Conclusion

In conclusion, Pharmapack's automatic labelling machine stands out as a beacon of efficiency and precision in the industry. From servo motor precision to advanced control systems, this machine is engineered to elevate performance and streamline operations in diverse labeling scenarios. With smart features that prioritize adaptability and user-friendly interfaces, Pharmapack's automatic labelling machine is a valuable asset for industries demanding top-tier labeling solutions.