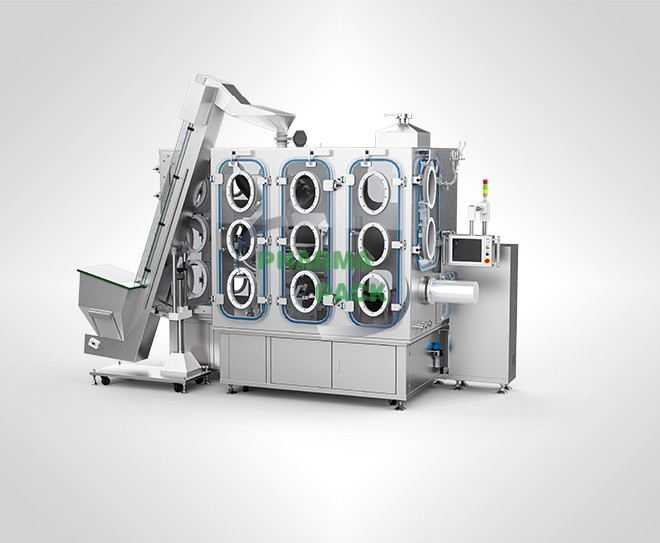

At Pharmapack, we pride ourselves on delivering cutting-edge solutions, and our Monoblock Filling Machine is no exception. The workflow begins with the bottle's entrance into the turntable infeeding station. This sophisticated system is designed to enhance efficiency and precision right from the start of the packaging process.

Conveyor Integration for Smooth Bottle Entry

The Monoblock Filling Machine's workflow commences with the smooth entry of bottles onto the turntable through a conveyor system. This integration ensures a seamless transition, minimizing disruptions and optimizing the overall efficiency of the filling process. At Pharmapack, we understand the importance of a well-coordinated workflow, and our turntable infeeding station sets the stage for precision and speed.

Precision-Guided Turntable Journey to Desiccant Station

Once on the turntable, the bottles are meticulously guided to the desiccant station. This precision-driven journey is a testament to the advanced engineering of our Monoblock Filling Machine. By utilizing the turntable as a conduit, we ensure that each bottle is positioned accurately for the subsequent stages of the packaging process.

Desiccant Insertion Expertise: Ensuring Product Integrity

Our Monoblock Filling Machine takes pride in its desiccant insertion capabilities, a crucial step in preserving the integrity of pharmaceutical products. The desiccant inserter within the workflow is designed for precision and efficiency.

Tailored Desiccant Cutting and Filling

The desiccant inserter seamlessly cuts the desiccant to the required specifications before delicately filling it into each bottle. This tailored approach ensures that the desiccant meets the unique needs of your products, providing an added layer of protection against moisture and environmental factors. Pharmapack's commitment to customization shines through in this crucial step of the workflow.

Quality Control: Desiccant Detection Station

Following desiccant insertion, our Monoblock Filling Machine incorporates a desiccant detection station. This station serves as a checkpoint, meticulously examining each bottle to verify the correctness of the desiccant placement. Bottles deemed 'not OK' are swiftly rejected, ensuring that only products meeting the highest standards proceed to the next stages of the workflow.

Precise Counting, Filling, and Capping: Ensuring Excellence

Pharmapack's Monoblock Filling Machine is not just about efficiency; it's about delivering excellence at every stage. The workflow seamlessly progresses to counting, filling, and capping, showcasing our commitment to precision and quality.

Counting and Filling Perfection

Once the bottles pass the desiccant detection station, they move to the counting and filling station. This stage is designed for precision, with accurate counting and filling mechanisms ensuring that each bottle receives the precise amount of product. Pharmapack's Monoblock Filling Machine is engineered to meet the highest standards of accuracy in pharmaceutical packaging.

Rigorous Quality Check: Post-Filling Detection Station

After counting and filling, the bottles undergo another round of scrutiny at the post-filling detection station. This final quality check is integral to our commitment to delivering flawless products. Bottles failing to meet the stringent quality parameters are promptly rejected, guaranteeing that only top-tier products advance to the capping stage.

Cap Sorting and Capping Excellence

The capping stage is where the Monoblock Filling Machine truly excels. The cap sorting unit precisely selects the correct cap for each bottle, ensuring a seamless and secure capping process. Any caps not meeting the stringent criteria are rejected, leaving only the perfectly capped bottles as the end result – a testament to Pharmapack's dedication to delivering products of unparalleled quality.

Conclusion

In conclusion, Pharmapack's Monoblock Filling Machine is a masterpiece of efficiency and precision. From the turntable infeeding station to the final capping stage, every step of the workflow is meticulously designed to ensure optimal performance and product excellence. Choose Pharmapack for a monoblock filling solution that sets the standard for pharmaceutical packaging.