Welcome to Pharmapack, your trusted partner in primary and secondary packaging solutions. We understand the importance of efficient and reliable packaging processes in the pharmaceutical industry. That's why we offer innovative equipment like the ALFBC-40 Continuous Horizontal Cartoner, designed to streamline your packaging operations. With a focus on separated cabinets design, low noise conveyors, mechanical pushers, and easy adjustment systems, our solutions ensure sanitary, safe, and efficient packaging. Join us at Pharmapack and elevate your packaging efficiency with our primary and secondary packaging solutions.

Unveiling the Working Principle of the ALFBC-40 Cartoner

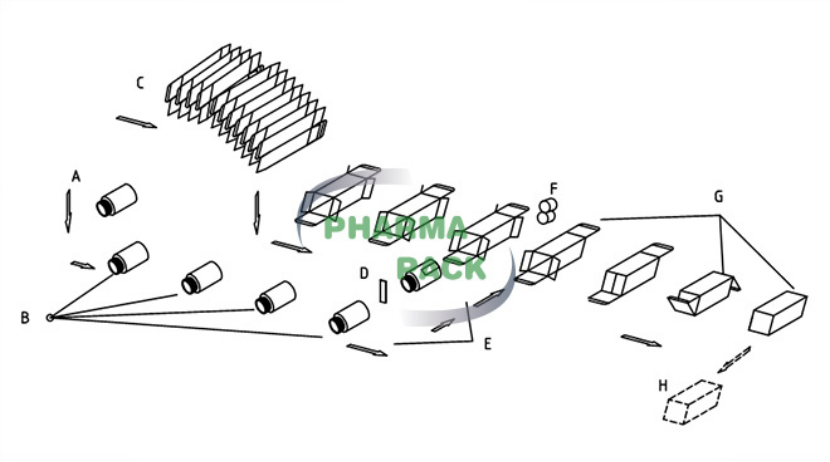

The ALFBC-40 Continuous Horizontal Cartoner optimizes your packaging process through its precise working principle. Firstly, product A is placed on the in-feeding conveyor B manually or automatically. Once the product is detected, the carton is sucked out from C and fed onto the conveyor, pre-opening it as it lowers down. The carton is then positioned on the station, while the leaflet is conveyed to the insertion point D. The leaflet is seamlessly inserted into the carton along with the product. As the carton passes through the F station, the flap is printed, completing the packaging process efficiently and accurately.

Embracing Features for Enhanced Packaging Performance

At Pharmapack, we prioritize innovation and functionality in our packaging solutions. The ALFBC-40 Cartoner boasts a range of features that optimize your packaging performance. The separated cabinets design ensures that driving parts and auxiliary parts are contained within the cabinets, preventing paper and material chips from entering the driving system. This design enhances sanitation, safety, and ease of maintenance. Our alloy chains-based in-feeding conveyor and cartons conveyor deliver low noise and stable running, ensuring efficient product and carton transportation.

Ensuring Efficiency and Reliability through Advanced Mechanisms

Pharmapack's ALFBC-40 Cartoner incorporates advanced mechanisms to guarantee high-speed and stable packaging. The carton sucking and pre-opening system utilizes separated servo motors, allowing for easy adjustment of horizontal and vertical directions. Mechanical pushers facilitate continuous cartoning during product in-feed, ensuring speed and stability. The flapping mechanism adopts a special ellipse similar coupler-point curve movement, further enhancing packaging efficiency. With one motor driving multiple parts, such as product in-feed, carton loading, flapping, indexing, coding, and carton out-feed, our equipment ensures mechanical synchronization and long-term performance without modification.

Conclusion

Pharmapack, a leader in primary and secondary packaging solutions, is dedicated to enhancing your packaging efficiency. Our ALFBC-40 Continuous Horizontal Cartoner, with its separated cabinets design, low noise conveyors, mechanical pushers, and advanced mechanisms, offers a reliable and efficient packaging solution. By choosing Pharmapack as your partner, you gain access to innovative technologies that optimize your packaging process. Elevate your packaging efficiency today with Pharmapack's primary and secondary packaging solutions. Trust us to deliver excellence and take your packaging operations to new heights.