Pharmapack, a leading provider of innovative packaging solutions, has introduced the LFBI-15 Intermittent Motion Horizontal Cartoner, a cutting-edge machine revolutionizing the field of medicine packaging. With its advanced features and state-of-the-art technology, this cartoner offers unmatched efficiency and precision in the packaging process. Designed for the food, pharmaceutical, cosmetics, and other industries, the LFBI-15 enables seamless packing of bottles, blister boards, and related materials, ensuring product integrity and safety.

Efficient and Versatile Packaging Solution

The LFBI-15 Intermittent Motion Horizontal Cartoner provides a comprehensive and efficient packaging solution for a wide range of products. With its versatile design, it can handle various materials, including bottles, blister boards, and material holders. This flexibility makes it an ideal choice for pharmaceutical companies, ensuring that different types of medications and medical products can be safely and securely packaged. Additionally, the LFBI-15 can be seamlessly integrated with Pharmapack's folding machine, enabling the inclusion of instruction manuals during the packaging process.

Streamlined Working Principle

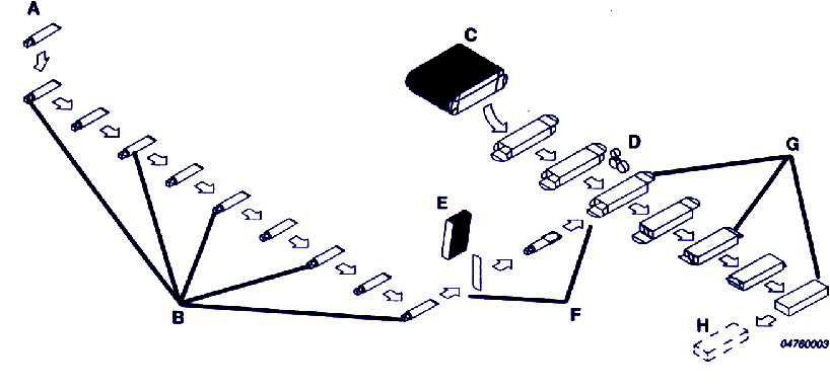

The LFBI-15 operates on a simple yet highly effective working principle. Products are placed manually or automatically on the feed conveyor, where an electric eye detects their presence. Once detected, the product is suctioned from the material level onto the U-shaped conveyor belt. The carton, stored in the silo, is then extracted and spread into a square shape at the designated position for coding. Simultaneously, the instruction manual is fed into the instruction inserting device.

Quality Assurance with Carton Reject Device

To maintain the highest standards of quality control, the LFBI-15 is equipped with a carton reject device at its outlet. This device plays a crucial role in detecting and rejecting any unqualified cartons, preventing defective packaging from reaching the market. By integrating this feature, Pharmapack ensures that only approved and properly sealed cartons proceed through the packaging line, reducing the risk of product damage or compromised safety.

Conclusion

Pharmapack's LFBI-15 Intermittent Motion Horizontal Cartoner is revolutionizing the medicine packaging industry. Its efficient and versatile design allows for the seamless packaging of various materials, ensuring product integrity and safety. With a streamlined working principle and the inclusion of an instruction manual insertion device, the LFBI-15 enhances the packaging process, improving efficiency and reducing manual labor. Furthermore, the built-in carton reject device guarantees quality control, preventing the distribution of defective cartons. By choosing Pharmapack's LFBI-15, pharmaceutical companies can elevate their packaging operations, meeting the highest standards of quality and safety in the industry.