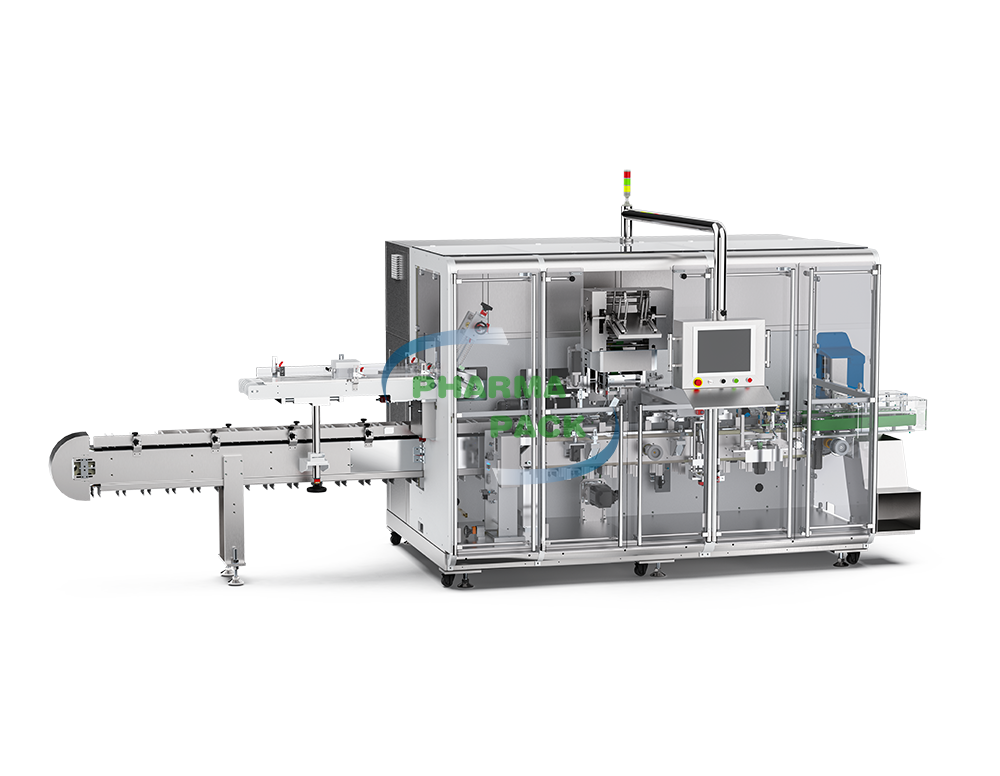

Here at Pharmapack, we're committed to improving productivity with cutting-edge packaging solutions that uphold perfect hygiene and safety. Our latest offering, the LFBI-10, is designed specifically for the automatic cartoning of medicines and cosmetics. This advanced cartoner not only meets Good Manufacturing Practice (GMP) standards but also incorporates features that make it an indispensable tool for modern packaging operations. In this article, we will explore the key features of the LFBI-10 that set it apart in the industry.

Space-Saving Design

One of the standout features of the LFBI-10 is its compact design, which conforms to GMP standards and relevant industrial safety regulations. The equipment’s small feet ensure that it occupies minimal space on the production floor, making it an ideal choice for facilities with limited room.

This space-saving design allows us to maximize our operational efficiency without compromising on safety or performance. By integrating the LFBI-10 into our packaging line, we can streamline our processes and maintain a clean, organized workspace, which is essential for meeting regulatory compliance and ensuring product quality.

Balcony Structure for Easy Maintenance

The LFBI-10 features a unique "Balcony" structure that enhances its usability and maintenance. In this design, the main driving part and the auxiliary driving components are positioned alongside the conveying mechanism. This configuration makes cleaning, maintenance, inspection, and product changeover significantly more convenient.

The "Balcony" structure is particularly beneficial for our operations. It prevents dust and debris from falling into the drive mechanism, safeguarding the integrity of the equipment and ensuring smooth operation. This thoughtful design reduces downtime and maintenance costs, allowing us to focus on our core production activities with confidence. As a result, the LFBI-10 stands out as a reliable cartoner that keeps our operations running efficiently.

Versatile Applications in Cartoning

The LFBI-10 is specially designed for the automatic cartoning of a wide range of products, including medicines and cosmetics. Its adaptability makes it a valuable addition to any packaging line, allowing us to cater to varied client needs without the hassle of frequent reconfiguration.

With its robust features and user-friendly interface, this cartoner can handle various carton sizes and styles, ensuring that we can package products efficiently and effectively. This versatility not only increases our production capacity but also enhances our ability to meet customer demands in a timely manner. By incorporating the LFBI-10 into our operations, we are well-equipped to navigate the complexities of modern packaging requirements.

Conclusion

In summary, Pharmapack is proud to present the LFBI-10, a cutting-edge cartoner that exemplifies our commitment to innovation, efficiency, and safety. Its compact design, convenient "Balcony" structure, and versatile applications make it an essential tool for businesses looking to enhance their packaging operations. By investing in the LFBI-10, we can ensure that our products are packaged with precision and adhere to the highest industry standards. We invite you to explore how this advanced cartoner can transform your packaging processes and contribute to your business’s success in a competitive marketplace. Together, we can achieve operational excellence and elevate the quality of our packaging solutions.