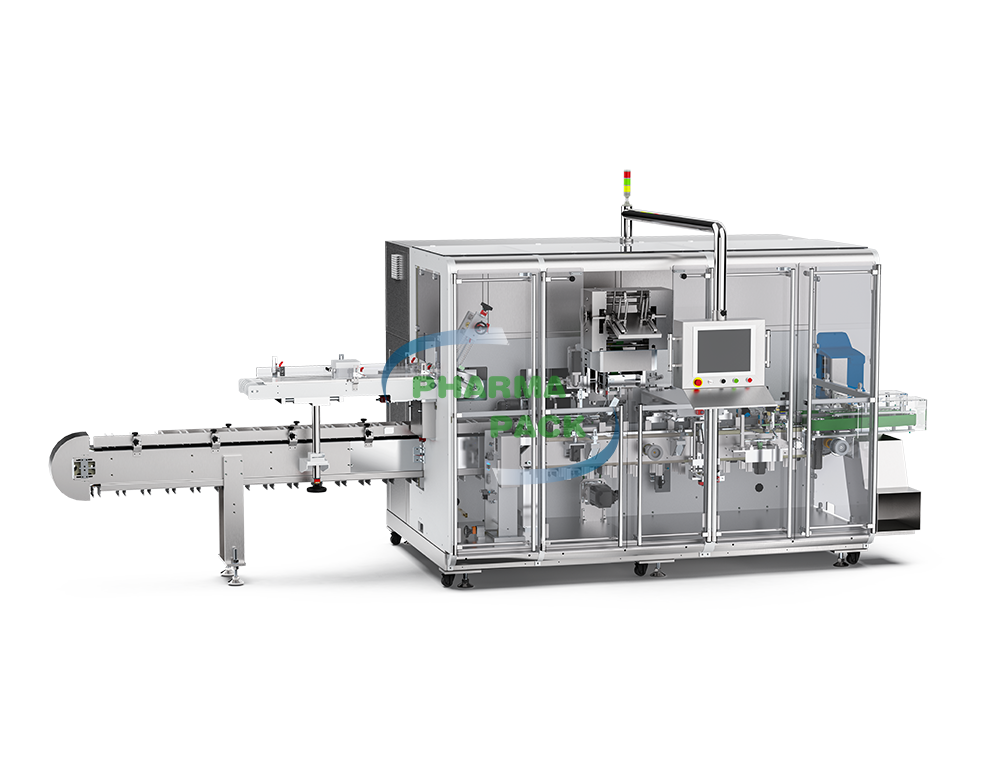

At Pharmapack, we’re passionate about redefining packaging solutions that cater to the diverse needs of our clients. Our latest innovation, the LFBI-10, is a sophisticated cartonator packing machine designed to elevate the efficiency and reliability of your packaging operations. With advanced features that streamline production and ensure high-quality sealing, the LFBI-10 stands out as an essential tool for any business focused on excellence in packaging. In this article, we will delve into the key attributes that make the LFBI-10 a game-changer in the industry.

Advanced Control with PLC and Touch Interface

The LFBI-10 incorporates a state-of-the-art PLC controller and a liquid crystal touch interface, which significantly enhance the convenience of production and product changeover. This advanced technology allows operators to easily monitor and control the packaging process, making adjustments as needed with just a few taps on the screen.

Moreover, the electrical wiring, noise level, and safety protection devices of the LFBI-10 comply with relevant industrial standards. This ensures not only operational efficiency but also a safe working environment for our team. By investing in this cartonator packing machine, we can assure our clients of a reliable and user-friendly solution that meets the highest industry benchmarks.

Versatile Sealing Capabilities

One of the standout features of the LFBI-10 is its versatility in sealing pre-glued cartons. It is designed to handle cartons with flaps inserted at the back or those with flaps inserted directly. This flexibility makes it suitable for a wide range of products, allowing businesses to adapt seamlessly to market demands.

Additionally, the LFBI-10 can be equipped with a hot melt glue device, enabling hot melt glue sealing for enhanced security and durability. For those looking for even more flexibility, the cartonator packing machine can also operate in a mixed mode, applying both flap insertion and glue sealing as required. This adaptability ensures that we can package various products efficiently while maintaining the quality and integrity of the packaging.

Enhanced Production Efficiency

The LFBI-10 is not just about versatility; it’s also engineered to maximize production efficiency. With its rapid changeover capabilities and intuitive controls, we can minimize downtime and keep our production lines running smoothly. The ease of adjusting settings means that operators can quickly switch between different products without extensive training or lengthy setup times.

By streamlining our operations with the LFBI-10, we can meet customer demands more effectively and improve our overall throughput. This efficiency is crucial in today’s fast-paced market, where responsiveness to changing demands can make all the difference.

Conclusion

Pharmapack is proud to introduce the LFBI-10, a cutting-edge cartonator packing machine that exemplifies our commitment to innovation and efficiency in the packaging industry. With its advanced PLC controller, versatile sealing options, and enhanced production capabilities, the LFBI-10 is designed to meet the diverse needs of our clients while ensuring high-quality packaging solutions. We invite you to explore how this exceptional cartonator packing machine can transform your packaging operations and contribute to your business’s success. Together, we can achieve excellence in packaging and elevate your brand to new heights.