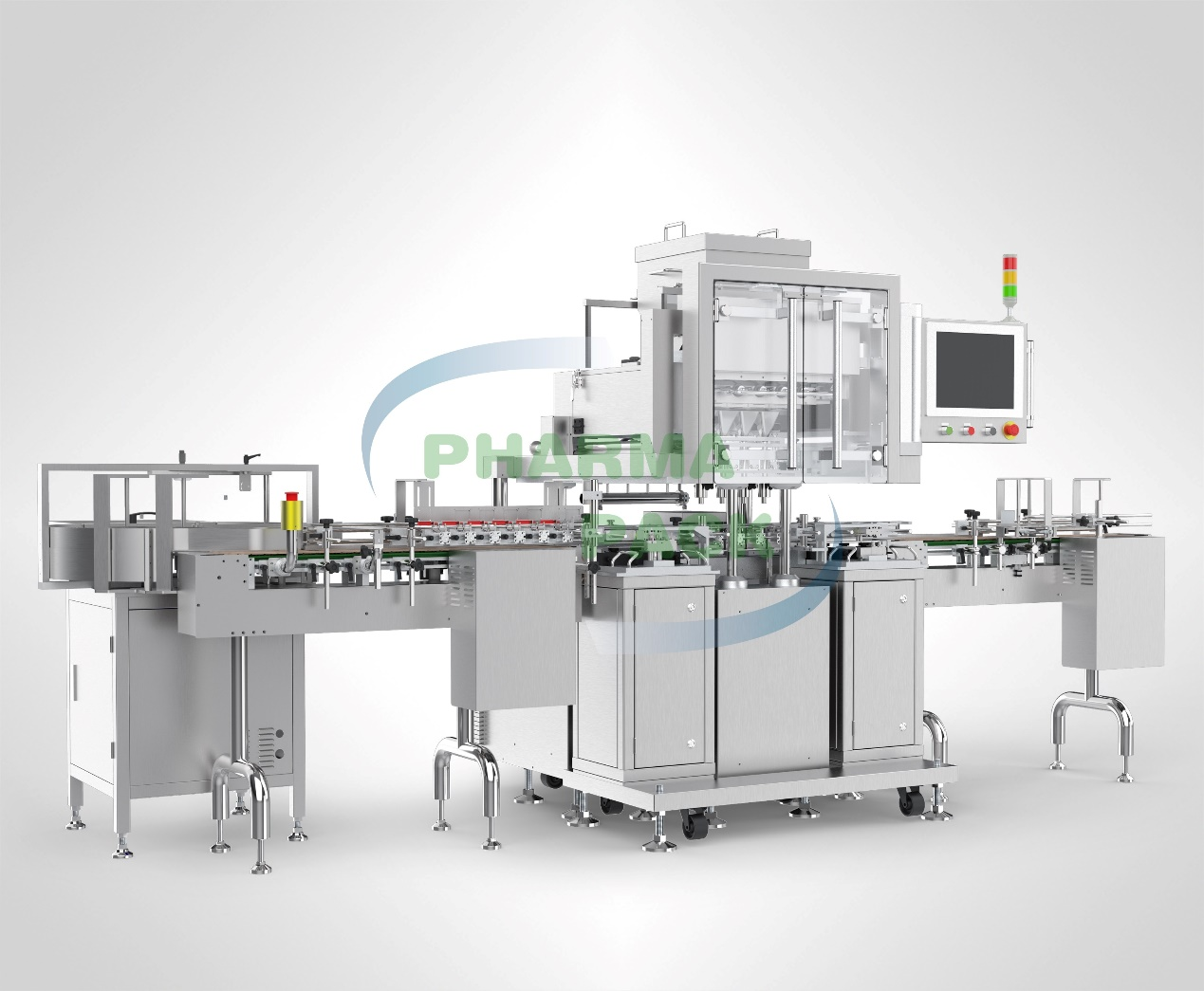

Innovative solutions that enhance efficiency in the pharmaceutical packaging industry are our dedicated focus here at Pharmapack. When it comes to high-tech bottle counting and filling machines, our PFM-1006WR model is at the very epicenter. This machine is designed to simplify operations while incorporating precision, user-friendliness, and adaptability to support our clients' diverse needs.

Durable and Easy to Maintain

The PFM-1006WR features an all-stainless steel structure combined with a transparent material box, ensuring durability and hygiene in every operation. One of the standout advantages of this design is that it requires no tools for dismantling, making it incredibly easy to clean and maintain. We understand that downtime for maintenance can be costly, so our focus on user-friendly design allows operators to quickly disassemble and wash the machine, ensuring it remains compliant with industry standards.

This ease of maintenance not only saves time but also enhances the overall efficiency of your production line. By incorporating the PFM-1006WR as your go-to bottle counting and filling machine, you can ensure that your operations run smoothly and consistently, meeting the demands of the market without compromising on quality.

Precision Control for Accurate Measurements

At the heart of the PFM-1006WR is its high-precision servo motor control filling system. This technology guarantees accurate measurements for every bottle, significantly reducing the risk of errors that can occur with less advanced machines. We recognise that precision is critical in the pharmaceutical industry, where every millilitre counts.

With our bottle counting and filling machine, you can trust that each product is filled to the exact specifications required, enhancing quality control and customer satisfaction. This commitment to precision not only helps maintain product integrity but also supports compliance with regulatory requirements, positioning your brand as a trusted leader in the industry.

Customizable Process Parameter Formulas

Flexibility is another key feature of the PFM-1006WR. The machine allows for the storage of various product adjustment parameter formulas, with the capability to save up to 30 unique process parameter formulas for future use. This feature is particularly beneficial for companies that handle multiple products, as it enables quick and efficient transitions between different filling processes.

By utilizing our bottle counting and filling machine, operators can easily switch between products without the need for extensive reconfiguration. This adaptability not only boosts productivity but also ensures that your operations can respond quickly to changing market demands, giving you a competitive edge.

Conclusion:

At Pharmapack, we believe that innovation is key to success in the pharmaceutical packaging industry. The PFM-1006WR bottle counting and filling machine exemplifies our commitment to delivering high-quality, efficient solutions that meet the evolving needs of our clients. With its durable design, precision control, and customizable features, the PFM-1006WR is the perfect addition to any production line.

We invite you to partner with us and explore how the PFM-1006WR can transform your operations. By choosing Pharmapack, you are not only investing in a reliable machine but also in a future of enhanced efficiency and quality in your packaging processes. Together, let’s elevate your production capabilities and ensure your brand stands out in the competitive marketplace.