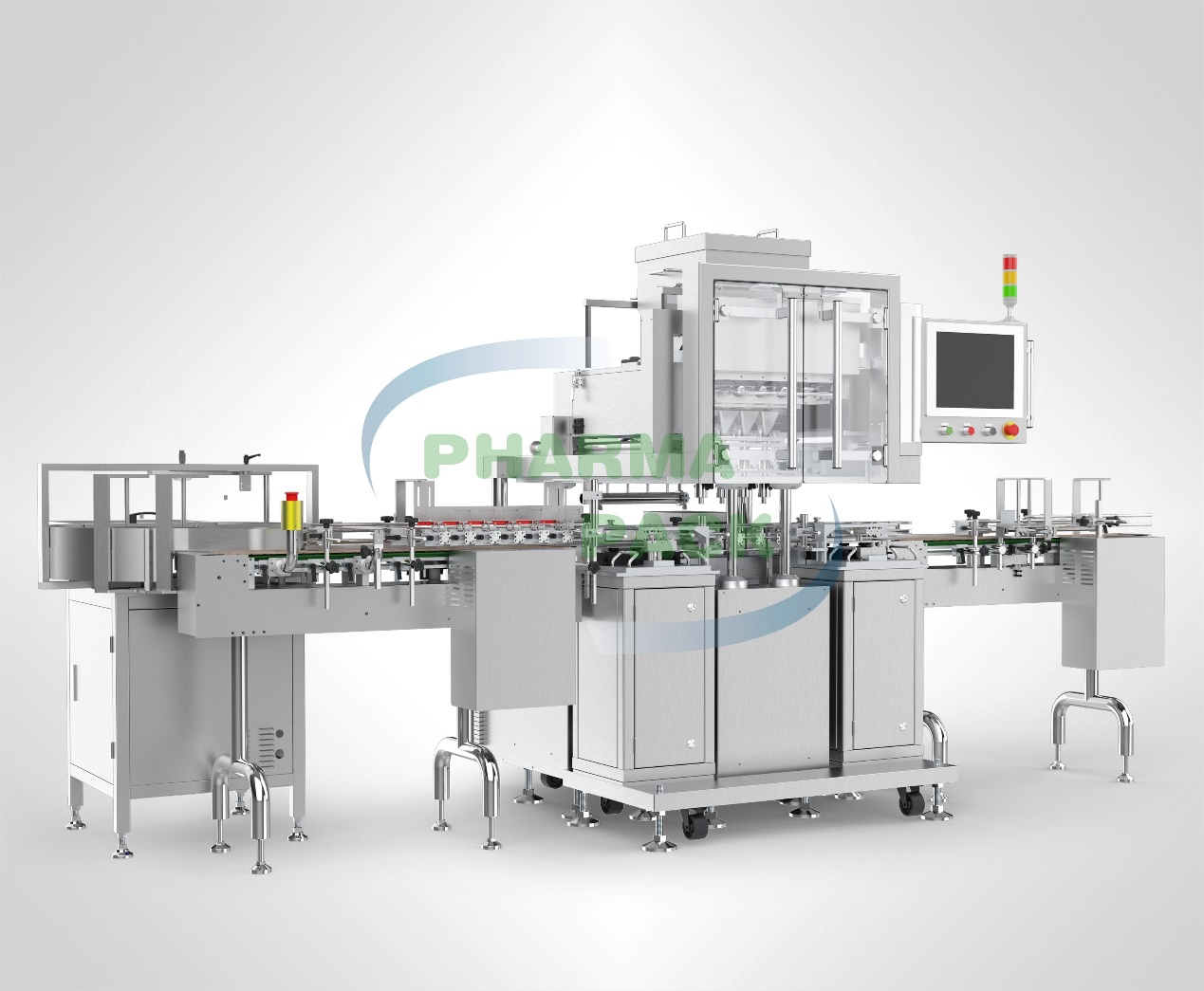

In the fast-paced world of pharmaceutical manufacturing, where precision and efficiency are paramount, we at Pharmapack are redefining the standards of packaging technology. Imagine a machine that not only streamlines your production line but also enhances the accuracy of every bottle filled. Introducing our PFM-1006WR—a game changer in the realm of pharmaceutical bottle packaging lines. With its innovative design and cutting-edge features, this machine is set to transform the way you approach your packaging processes.

Precision in Bottle Feeding

The PFM-1006WR utilizes a screw positioning system for bottle feeding, ensuring accurate placement every time. This precision is crucial for maintaining the integrity of the filling process and preventing any operational mishaps. We understand that accuracy is paramount in pharmaceutical packaging, where even the slightest error can lead to significant consequences.

With this machine, the bottle feeding process is seamless and efficient, allowing for a smooth transition from loading to filling. This attention to detail not only minimizes waste but also maximizes production output, making the PFM-1006WR an essential component of any pharmaceutical bottle packaging line.

User-Friendly Control System

One of the standout features of the PFM-1006WR is its touch screen PLC control system. This user-friendly interface simplifies operation, allowing operators to easily monitor and adjust settings with minimal training. Importantly, the machine is designed to remain in standby mode when no bottles are detected, conserving energy and reducing wear on the equipment.

This intelligent design feature enhances the overall efficiency of your pharmaceutical bottle packaging line. By ensuring that the machine only operates when necessary, we help you save on operational costs while maintaining high productivity levels. Our focus on user-friendly technology makes the PFM-1006WR a valuable asset in any production environment.

High-Quality Materials and Components

At Pharmapack, we prioritize quality in every aspect of our machines. The PFM-1006WR is constructed with 304 stainless steel in all parts that come into contact with materials, ensuring durability and easy cleaning. This choice of materials not only meets industry hygiene standards but also extends the lifespan of the machine.

Furthermore, we source all motors, cylinders, electrical accessories, and pneumatic components from well-known brands. This commitment to quality ensures that your pharmaceutical bottle packaging line operates reliably and efficiently. By investing in a PFM-1006WR, you are choosing a machine that is built to last, reducing the risk of downtime and maintenance issues.

Conclusion:

At Pharmapack, we believe that innovation and quality are fundamental to success in the pharmaceutical packaging industry. The PFM-1006WR embodies our commitment to delivering high-performance solutions that meet the diverse needs of our clients. With its precision bottle feeding, user-friendly controls, and high-quality materials, the PFM-1006WR is the perfect addition to your pharmaceutical bottle packaging line.

We invite you to partner with us and discover how the PFM-1006WR can transform your production processes. Together, we can enhance your operational efficiency and ensure that your products meet the highest standards of quality and safety. Choose Pharmapack for innovative solutions that elevate your pharmaceutical packaging capabilities and help you achieve your business goals.