In today's fast-paced pharmaceutical and cosmetic sectors, efficient packaging solutions are more crucial than ever. As industries strive for higher productivity and quality, the demand for innovative equipment, such as bottle carton packaging machines, continues to rise. At Pharmapack, we pride ourselves on being at the forefront of packaging technology, delivering solutions that not only meet but exceed industry standards.

Innovative Design Features of the LFBI-10 Intermittent Horizontal Cartoner

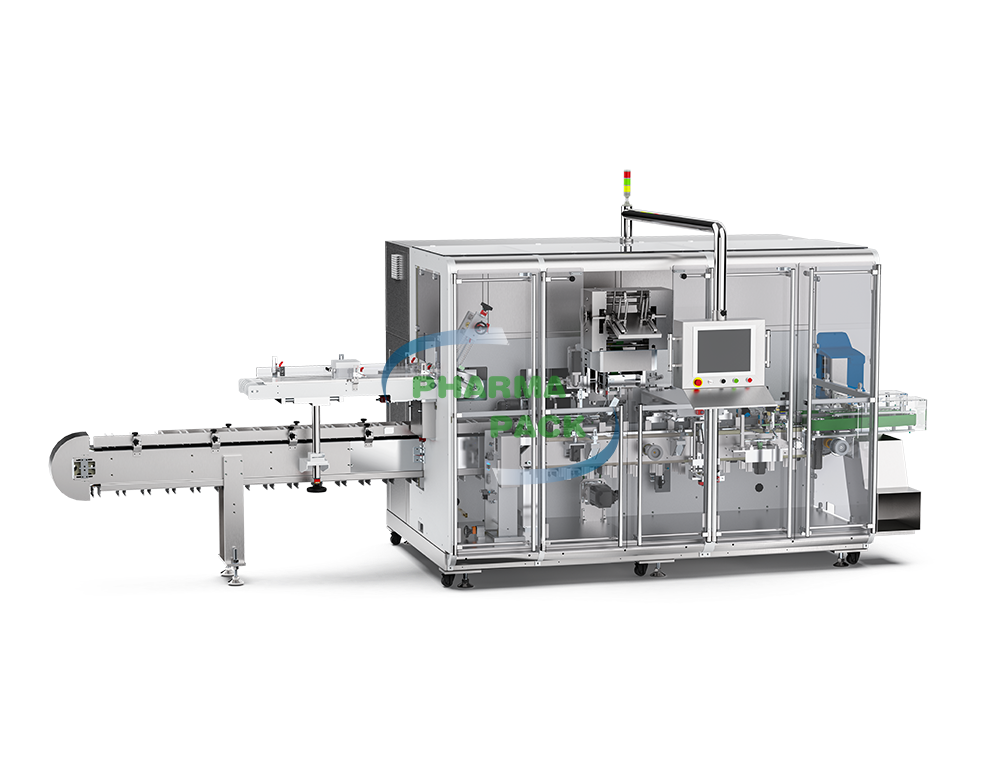

One of our flagship products, the LFBI-10 Intermittent Horizontal Cartoner, exemplifies the cutting-edge technology that Pharmapack offers. This bottle carton packaging machine is specifically designed for the automatic cartoning of medicines and cosmetics, ensuring a seamless and efficient packaging process.

A standout feature of the LFBI-10 is its unique "Balcony" structure. This innovative design places the main driving components and auxiliary mechanisms on the sides of the conveying system. This arrangement enhances operational efficiency by providing easier access for cleaning and maintenance. With the LFBI-10, operators can quickly inspect and maintain the machine, minimizing downtime and maximizing productivity.

Furthermore, the "Balcony" structure is designed to prevent dust and debris from falling into the drive mechanism. This feature is particularly important in the pharmaceutical and cosmetic industries, where cleanliness is paramount. By ensuring a contamination-free environment, our bottle carton packaging machine helps maintain the integrity and quality of the products being packaged.

Advantages of Implementing Pharmapack's LFBI-10 in Your Operations

Integrating Pharmapack's LFBI-10 into your production line brings numerous advantages. With a maximum production speed of up to 100 cartons per minute, this bottle carton packaging machine significantly boosts efficiency, allowing businesses to meet high demand without sacrificing quality.

Moreover, the LFBI-10 is designed for easy product changeovers. The streamlined process ensures that manufacturers can switch between different products with minimal disruption. This flexibility is vital in today's market, where adaptability is key to staying competitive.

The design of the LFBI-10 not only simplifies cleaning but also enhances overall operational effectiveness. The side-mounted driving components allow for easy access, making routine maintenance a breeze. This thoughtful design minimizes the risk of contamination, contributing to higher quality standards in your packaging process.

By choosing Pharmapack's LFBI-10, you're investing in a solution that enhances your production capabilities while ensuring compliance with industry standards. Our commitment to quality and innovation means that you can trust our machines to deliver reliable performance day in and day out.

Conclusion

In conclusion, as the demand for efficient bottle carton packaging machines continues to grow, Pharmapack remains dedicated to providing state-of-the-art solutions tailored to the pharmaceutical and cosmetic industries. Our LFBI-10 Intermittent Horizontal Cartoner stands out for its innovative features, operational efficiency, and commitment to quality. By implementing our packaging solutions, you'll not only enhance your production speed but also ensure the safety and integrity of your products. Choose Pharmapack for your packaging needs and experience the difference that quality technology can make.