The success of any packaging line in the heavily regulated pharmaceutical sector depends on accuracy, productivity, and cost-effectiveness. To overcome these obstacles, Pharmapack, a reliable supplier in pharmaceutical packaging solutions, provides state-of-the-art technology. At the core of our innovations is the automatic counter, an essential part that helps improve production processes, save operating costs, and increase accuracy. This post will examine how our automatic counter technology improves pharmaceutical packing, guaranteeing accuracy and superior performance throughout the entire procedure.

Cutting-Edge Accuracy: How Pharmapack's Automatic Counter Ensures Precision

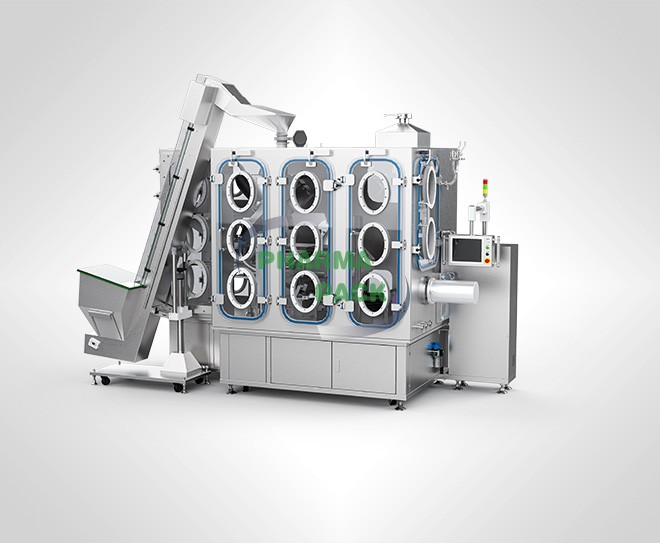

The pharmaceutical industry demands rigorous standards of accuracy, especially when it comes to counting products like tablets, capsules, and other oral medications. Pharmapack automatic counter system delivers the level of precision required to meet these standards consistently. Our automatic counter uses advanced sensors and intelligent software algorithms to ensure that every product is counted accurately, preventing errors such as underfilled or overfilled bottles.

Maintaining this level of accuracy is critical not only for compliance but also for maintaining product integrity. Incorrect counts can lead to costly product recalls, regulatory fines, and damaged reputations. Pharmapack automatic counter helps pharmaceutical manufacturers avoid these risks by ensuring that each package contains the correct number of items, thus enhancing product reliability and customer trust.

By integrating this advanced technology into packaging lines, we enable manufacturers to increase production speed without sacrificing accuracy, ensuring that packaging is both efficient and compliant with the highest industry standards.

Optimizing the Capping Process: The Integrated Cover Hanging System

Pharmapack innovative automatic counter system goes beyond just counting products; it also enhances the capping process through its integrated cover hanging system. This system, linked to the turntable and screw cap, ensures that bottles are capped securely and consistently, preventing issues such as loose or improperly sealed caps that can compromise product safety.

The cover hanging system works in harmony with the automatic counter to ensure that after each product is counted and filled, the capping process is seamlessly integrated into the packaging line. The synchronized movement between the turntable, the cover system, and the screw cap ensures that each bottle is sealed with precision, reducing the need for manual intervention and minimizing the risk of contamination.

By optimizing the capping process, we help pharmaceutical manufacturers increase production efficiency, improve packaging quality, and ensure that each product is securely sealed before reaching the consumer.

Conclusion

Pharmapack automatic counter technology offers a transformative solution for pharmaceutical packaging. By delivering precise counting, cost-effective performance through the combo machine, and optimizing the capping process, we provide manufacturers with an all-in-one system that meets the industry's demanding standards. Whether you're looking to improve accuracy, reduce costs, or increase operational efficiency, Pharmapack automatic counter is the ideal solution for modern pharmaceutical packaging. With our advanced technology, we help ensure that every package is accurately counted, securely sealed, and ready to deliver high-quality pharmaceutical products to the market.