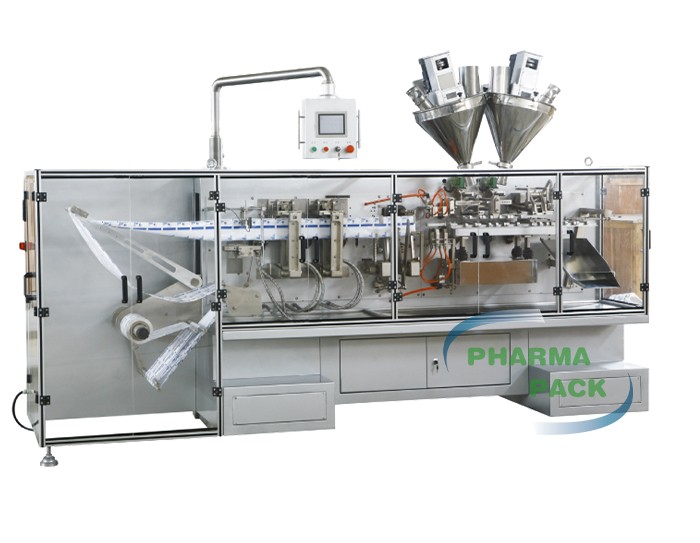

In an era where speed and precision are critical for maintaining competitive edge, the PB-1800AL Horizontal Packing Machine by Pharmapack is setting new standards for packaging automation. Designed for high-throughput production lines, this cutting-edge solution combines reliability and speed with seamless integration into existing workflows. Its dual outlet design and user-friendly interface minimize manual effort, making it the perfect tool for industries that demand both efficiency and quality. Whether in food, pharmaceuticals, or consumer goods, the PB-1800AL is transforming how manufacturers approach their packaging needs, offering enhanced productivity and consistent results with every cycle.

Discover the PB-1800AL Horizontal Automatic Packing Solution

Pharmapack PB-1800AL horizontal packing machine is designed to optimize the packaging process with a focus on speed, precision, and versatility. This machine features a dual outlet design, allowing it to simultaneously package products at a higher throughput, making it ideal for busy production lines. Its horizontal structure provides increased stability and smoother operation, while its intuitive interface and automatic functions reduce the need for manual intervention, further streamlining the entire process. In high-demand production environments, where time is critical, the PB-1800AL stands out as an efficient solution that helps manufacturers meet tight deadlines and maintain consistent product quality.

Advanced Features: Diamond and Line-Tearing Areas

One of the most remarkable aspects of the PB-1800AL horizontal packing machine is its inclusion of both diamond and line-tearing areas, offering enhanced tearability and convenience for end-users. The diamond tearing area is designed to provide a clean and easy-to-tear package, allowing consumers to open products with minimal effort. This feature not only improves user experience but also reduces the risk of damage to the packaging, ensuring the integrity of the contents inside.

The line-tearing area, another key innovation, provides a precise and controlled way for products to be opened along a defined tear line. This feature helps maintain product freshness and security by ensuring that the package opens predictably and without compromise. These tearing areas are particularly beneficial in packaging for food, pharmaceuticals, and consumer goods, where product integrity and ease of access are critical.

How Pharmapack Ensures Superior Quality and Efficiency

Our goal at Pharmapack is to provide packaging solutions that increase efficiency and cut down on waste. For example, our PB-1800AL horizontal packing machine demonstrates this dedication. This machine's sophisticated automation minimises manual labour, lowers the possibility of mistakes, and guarantees consistently high-quality packaging.

In addition to its superior performance, the PB-1800AL helps businesses lower operational costs through faster processing times and reduced material waste. The precision engineering of the machine not only improves packaging consistency but also cuts down on the need for rework or product disposal. As a result, manufacturers benefit from increased productivity, higher cost savings, and a more sustainable production process.

Conclusion

Pharmapack PB-1800AL horizontal packing machine is not just a tool for today-it's an investment in long-term operational efficiency and product excellence. By choosing our cutting-edge packaging solutions, businesses can stay ahead of the competition and meet evolving consumer demands.