As the pharmaceutical industry evolves, so does the technology behind pharmaceutical packaging equipment. Pharmaceutical packaging not only plays a pivotal role in ensuring product integrity but also significantly impacts production efficiency and cost-effectiveness. Pharmapack, a reliable supplier in the packaging equipment industry, is dedicated to providing innovative solutions that meet the growing demands of the pharmaceutical sector. In this article, we'll explore the role of pharmaceutical packaging equipment, highlight the features that make our PFM-1006WR stand out, and explain why choosing us for your packaging solutions is a smart move.

The Role of Pharmaceutical Packaging Equipment

Pharmaceutical packaging equipment is crucial for maintaining the quality and safety of pharmaceutical products from manufacturing to distribution. Proper packaging helps protect drugs from contamination, degradation, and environmental factors that could compromise their effectiveness. Additionally, efficient packaging equipment ensures that products are securely sealed, labelled correctly, and ready for distribution.

In today's highly regulated environment, the pharmaceutical industry demands packaging solutions that not only meet safety standards but also maintain product integrity throughout the supply chain. Automated pharmaceutical packaging equipment, such as the machines offered by Pharmapack, simplifies and streamlines the packaging process, reducing the risk of human error and increasing the speed and precision of production.

Features That Set Pharmapack's PFM-1006WR Apart

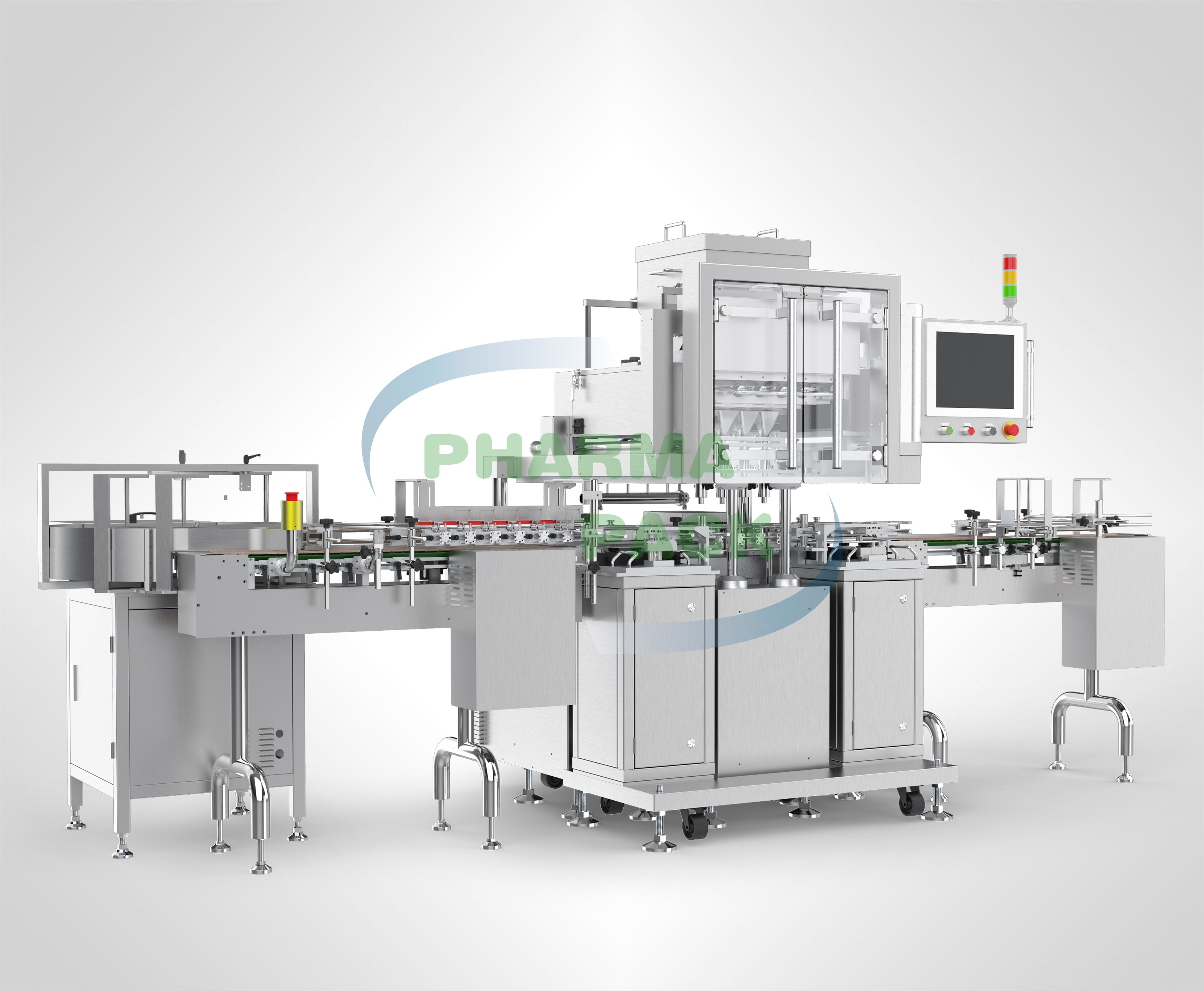

One standout product in our portfolio is the PFM-1006WR, a state-of-the-art pharmaceutical packaging machine designed to meet the unique demands of the industry. This packaging solution combines cutting-edge technology with user-friendly features to deliver exceptional performance and efficiency.

Intuitive Touch Screen PLC Control

The PFM-1006WR is equipped with an intuitive touch screen PLC (Programmable Logic Controller) control system that allows operators to easily manage and monitor the packaging process. This advanced interface simplifies machine operation, making it accessible even for those with limited technical expertise. The touchscreen interface provides real-time data, enabling operators to adjust settings and parameters with ease, ensuring optimal performance and reducing downtime.

No Bottle, No Filling Functionality

One of the standout features of the PFM-1006WR is its "no bottle, no filling" functionality. This innovative feature automatically halts the filling process if no bottles are present, preventing product waste and ensuring that pharmaceutical products are filled only when the packaging process is properly aligned. This feature not only reduces the likelihood of product waste but also promotes environmental sustainability by minimizing unnecessary waste and loss.

Choosing Pharmapack for Your Packaging Solutions

When it comes to pharmaceutical packaging equipment, choosing a reliable and experienced partner is crucial. Pharmapack is a trusted name in the industry, known for its commitment to quality, precision, and innovation. With years of expertise in the field, we have earned a reputation for providing cutting-edge solutions that help pharmaceutical companies increase operational efficiency, reduce costs, and improve product quality.

Conclusion

In an industry where quality and precision are paramount, our dedication to developing advanced pharmaceutical packaging equipment like the PFM-1006WR sets them apart as a leader in innovation. By prioritizing product integrity, user-friendly design, and efficiency, we provide solutions that align with the evolving needs of pharmaceutical companies. Choosing us means partnering with a company that values both progress and reliability, ensuring your packaging operations meet the highest standards of safety and effectiveness.