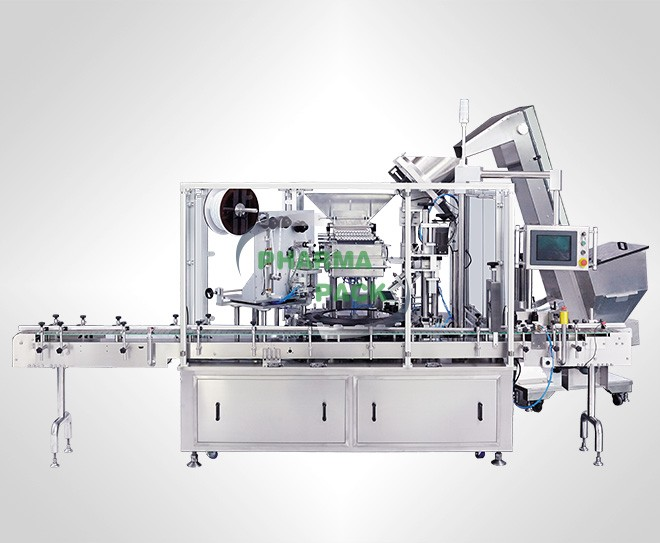

We take great pride in becoming the industry standard for pharmaceutical packaging innovations here at Pharmapack. Our commitment to quality and efficiency is embodied in our flagship product, the LF-0601CD Monoblock tablet & capsule counting line. This advanced machine streamlines the entire packaging process, ensuring that pharmaceutical companies can meet their production targets while maintaining the highest standards of safety and accuracy.

Efficient Infeeding and Desiccant Insertion

The journey of our packaging process begins with the bottle enters the turntable infeeding station by conveyor, where efficiency is paramount. As the turntable rotates, it smoothly transports each bottle to the desiccant station. Here, our desiccant inserter cuts and fills the desiccant into each bottle, an essential step to maintain product integrity. After this, the turntable brings the bottle into the desiccant detection station to verify whether the insertion was successful. Bottles that do not meet our stringent quality standards are promptly rejected, while those that pass the inspection are routed to the counting and filling station. This meticulous attention to detail ensures that every bottle is prepared correctly, significantly reducing the risk of contamination and preserving the potency of the pharmaceuticals inside. Our automatic tablet counter technology guarantees accurate counts, minimizing waste and maximizing efficiency.

Accurate Counting and Filling Process

Once the bottles have passed the desiccant inspection, they flow seamlessly to the counting and filling station. Here, our automatic tablet counter comes into play, accurately counting the tablets or capsules before they are filled into the bottles. This precision is critical in the pharmaceutical industry, where even the slightest error can lead to significant consequences. After counting, the bottles are directed to another detection station to ensure that each one is filled correctly. Bottles that do not meet our quality standards are rejected, while the compliant bottles proceed to the capping stage. Our robust design ensures that power consumption remains efficient, operating at just 3.8Kw. This energy efficiency not only reduces operating costs but also aligns with our commitment to sustainable practices.

Seamless Capping and Quality Assurance

The final stage of our LF-0601CD Monoblock line is the capping process. Our cap sorting unit meticulously ensures that the correct cap is sent to the capping station, where it is securely placed on each bottle. Bottles with improper capping are immediately rejected, while those with successfully applied caps are deemed ready for distribution. This rigorous quality assurance process ensures that our clients receive only the highest quality products. The LF-0601CD is designed with dimensions of 3300 (L)×2600(W)×2500(H) and weighs 1500kg, including the elevator, making it a compact and efficient addition to any production line. With its advanced technology and streamlined processes, Pharmapack is proud to offer a solution that optimizes both space and productivity.

Conclusion

In conclusion, Pharmapack is dedicated to providing reliable solutions in pharmaceutical packaging through our LF-0601CD Monoblock tablet & capsule counting line. With our focus on efficiency, accuracy, and sustainability, we are confident that our automatic tablet counter will meet and exceed the needs of our clients. By choosing Pharmapack, you are investing in a partnership that prioritizes quality and innovation, ensuring your products are packaged to the highest standards.