당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

2. Touch screen in English and Chinese, PLC control, automatic and efficient bottle management and automatic stopping of clogged bottles in accordance with production conditions.

3. Equipped with electrostatic elimination device to clean plastic bottles and internal dust

4. Applicable to a variety of plastic bottle specifications, such as round bottles, square bottles and shaped bottles, etc., the product specifications can be changed easily and quickly.

5. Bottle feeding clamping belt does not drop powder and does not pollute bottles

6. Touch screen one-key production change function: you can select the program formula of various bottle types on the touch screen, and realize automatic adjustment of one-key production change under the action of servo adjustment mechanism

Stainless steel large-capacity silo, large capacity, no need for frequent refilling, automatic alarm when there is no bottle; bottle storage silo door can be automatically opened and closed by control, convenient for refilling and dustproof

It is used to separate the bottles that just come out from the turntable; when changing the bottle type, through the role of servo motor and screw nut mechanism, the bottle dividing wheel can be in different positions to adapt to different sizes of bottles.

Clamping bottle management belt is controlled by servo motor, no need to replace the mold, to achieve automatic adjustment of one key to change the production function.

The bottle standing mechanism is used to stand up the bottle mouth in the lying state; through the role of servo motor and screw nut mechanism, the bottle standing block can be at different heights, so as to adapt to different sizes of bottles; the bottle standing mechanism is used to stand up the bottle mouth in the lying state; through the role of servo motor and screw nut mechanism, the bottle standing block can be at different heights, so as to adapt to different sizes of bottles

When changing the bottle type, through the role of servo motor and screw nut mechanism, the vacuum nozzle and high-pressure line ion wind nozzle can be at different heights, so as to adapt to different sizes of bottles;

When the clamping belt sends the bottle out, its speed is synchronized with the main conveyor belt and does not reverse the bottle

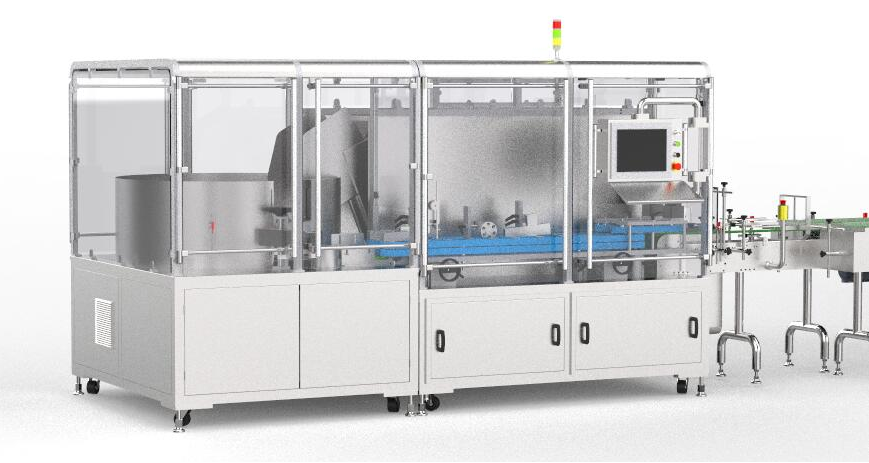

The maximum production speed of ALFU-40CAS is 400 bottles/min, the applicable bottles are square bottles 35~90mm, round bottles φ35~φ100mm applicable bottle height 50~210mm, power supply AC380V 50/60HZ, power about 10KW, air pressure 0.5~0.7Mpa, air consumption about 500L/min clean air, shape size about 3150mm( L) × 1800mm (W) × 1850mm (H), weight about 1600kg.

Bottle unscrambling machine ALFU-40CAS is built with high quality material, with production situation automatic and efficient bottle arrangement, with production situation automatic and efficient bottle arrangement, with outstanding structural advantages, can help you achieve high speed bottle arrangement!