당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

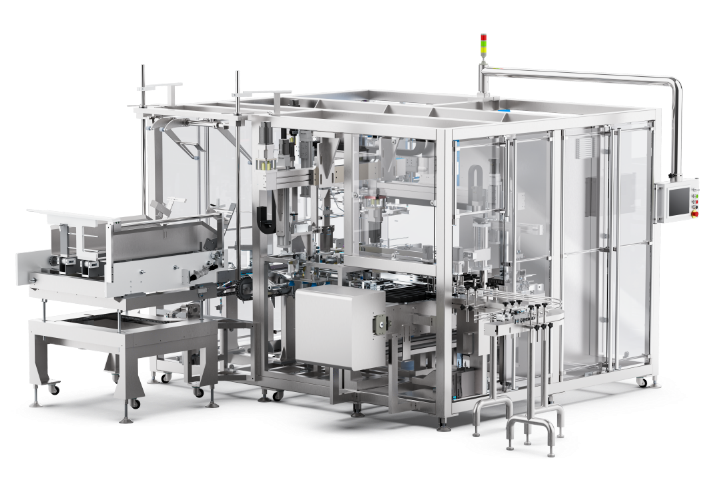

With the continuous advancement of manufacturing technology, the case making and packing machine has become one of the main equipment in the packaging industry. The all-in-one box making and boxing machine launched by pppharmapack is a multi-functional machine that integrates box development, bottle quantitative retraction, and box folding and sealing, which greatly improves production efficiency and packaging quality. This article will introduce and analyze in detail from the aspects of device features, application scenarios, advantages and disadvantages.

As one of the world's leading packaging machinery manufacturers, pppharmapack has been committed to creating efficient, reliable and safe packaging equipment. The all-in-one case making and packing machine is one of the representative products, and its main features are as follows.

1. Quickly adjust to the programmed packaging size

The all-in-one case making and packing machine uses digital technology and can be quickly adjusted to the required packaging size. At the same time, the device can also store combinations of various sizes, which facilitates quick switching during production.

2. Simplified mechanical system

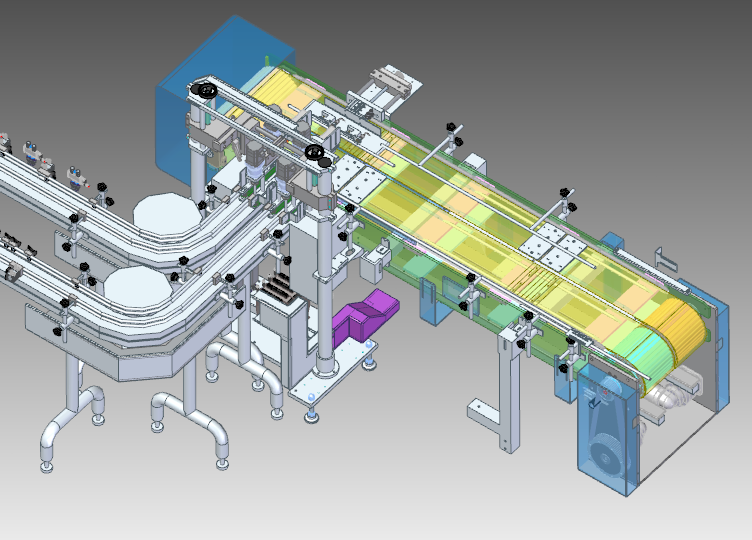

The all-in-one box making and packing machine uses an electronic synchronous automation platform to simplify the mechanical system to a new electronic synchronous automation platform. The mechanical system employs a combination of servo drives, electronic cams and a compact in-line variable speed system that greatly reduces the wiring of the machine and most of the adjustment chain and its associated mechanical counters.

3. High precision and reduced noise level

The servo motor control system of the case making and packing machine can achieve higher operating accuracy and lower noise level, and provide better operating environment and sanitation conditions.

4. Ergonomic operating experience

The all-in-one box making and boxing machine is designed on the basis of ergonomic requirements. The operation process is simple and requires less maintenance, ensuring a hygienic environment and reducing maintenance costs. The optimized design of the timing belt greatly reduces potential problems with dust and residual grease, and eliminates the need for regular periodic chain adjustments and maintenance.

5. It is convenient to change the variety and adjust

All adjustment points are equipped with regulators, scales and variety specification tables, and only need to be adjusted according to the set parameter values. The operation is more convenient and faster.

6. High-quality electrostatic spraying treatment

The appearance of the case-making and packing machine adopts electrostatic spraying treatment technology to ensure a beautiful, clean and high-quality appearance.

7. Compact cabinet design

The compact cabinet design of the Famagal all-in-one box making and packing machine not only reduces the space used by the customer, ensures the safety of the equipment, but also ensures that the customer can make full use of the space.

The case-making and packing machine is used in a wide range of fields, mainly including organic chemical, food, pharmaceutical manufacturing and other fields. In the field of chemical industry, the case making and packing machine can be applied to the packaging of food cans, beverage bottles, cosmetic bottles, medicine bottles and other bottle types. In healthcare and pharmaceuticals, case-filling and case-filling machines can be used for the entire pharmaceutical product line packaging process. In addition, in industries such as the electronic product industry and hardware tools, the integrated case making and packing machine can also be applied to product packaging of various sizes.

In general, the all-in-one Famaga case making and packing machine is an efficient, reliable and safe packaging equipment, which is suitable for many fields. The device can be quickly adjusted to the desired package size, reducing manual operations and conforming to the ergonomic operating experience. Compared with traditional packaging equipment, this equipment has more advantages and is more convenient and quick to use.

In today's fierce market competition, pppharmapack is committed to creating differentiated advantages through quality and innovation. We not only provide customers with the most advanced technology and solutions, but also help customers improve production efficiency, reduce costs and enhance core competitiveness. Our products have been widely used in production lines in many industries, and have been highly appraised and recognized by customers. If you have any packaging machine needs, please feel free to contact us.